-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 25. 2025, 16:03:18

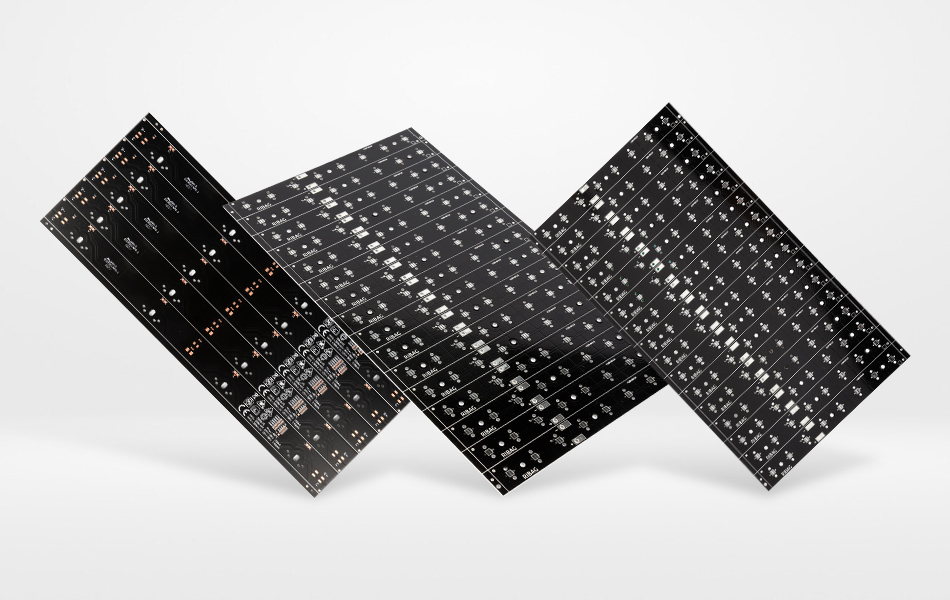

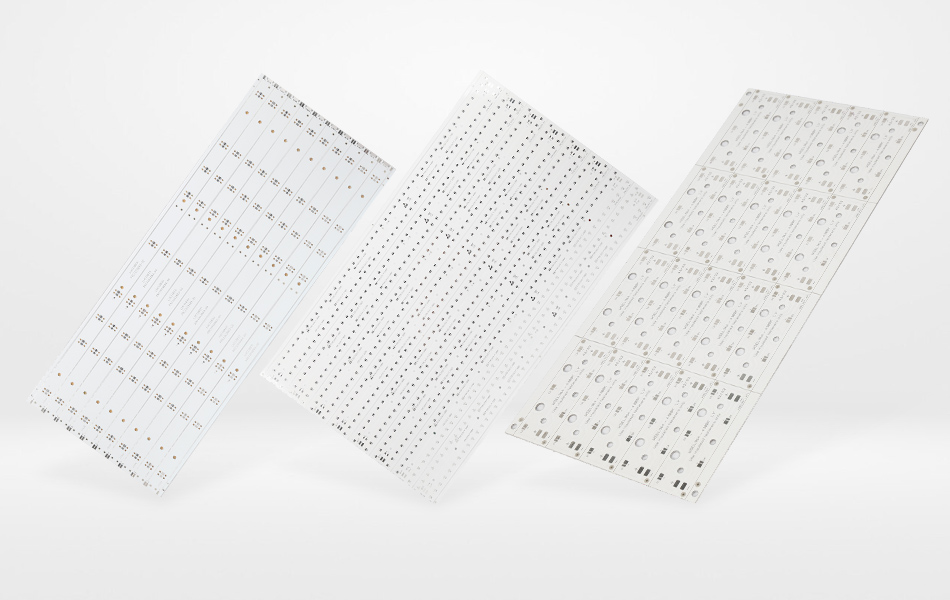

In the landscape of high-performance electronic materials, HA80 Aluminum PCB has emerged as a specialized solution tailored for applications demanding exceptional thermal management, electrical stability, and mechanical durability. Designed to address the challenges of power-dense electronics in industries such as automotive, industrial automation, and LED lighting, HA80 Aluminum PCB combines advanced material engineering with precision manufacturing to deliver consistent performance in harsh operating environments. This article explores the material composition, performance attributes, application ecosystems, and quality standards of HA80 Aluminum PCB, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Material Architecture of HA80 Aluminum PCB

HA80 Aluminum PCB is engineered as a multi-layer composite, with each component optimized to balance thermal conductivity, electrical insulation, and structural integrity:

Core Layer Composition

Aluminum Substrate: The foundational layer of HA80 Aluminum PCB is crafted from high-grade aluminum alloy, selected for its uniform thermal conductivity and mechanical rigidity. This substrate acts as a primary heat dissipation pathway, efficiently transferring heat from active components to the surrounding environment while resisting warping under thermal stress—a critical feature in high-power applications.

Thermally Enhanced Dielectric Layer: A proprietary dielectric material forms the insulating barrier between the aluminum substrate and copper circuit layer. Formulated with ceramic reinforcements and high-performance polymers, this layer minimizes thermal resistance to enable efficient heat transfer while maintaining high electrical insulation strength. Its stable dielectric properties (low dissipation factor, consistent dielectric constant) ensure minimal signal loss in high-frequency scenarios.

High-Purity Copper Circuit Layer: Bonded to the dielectric layer via advanced lamination techniques, the copper circuit layer uses ultra-pure foil to ensure low electrical resistance and uniform heat spreading. Precision etching processes create fine, consistent circuit traces, supporting both high-density designs and impedance-controlled applications.

This architecture creates a synergistic thermal-electrical system, where heat management and signal integrity are seamlessly integrated to meet the demands of power-dense electronics.

Key Performance Attributes of HA80 Aluminum PCB

HA80 Aluminum PCB distinguishes itself through a set of performance characteristics that make it ideal for demanding applications:

Superior Thermal Management

Efficient Heat Dissipation: The combination of high-conductivity aluminum substrate and low-thermal-resistance dielectric layer ensures rapid heat transfer from components such as power transistors, LEDs, and motor drivers. This minimizes thermal hotspots, a common cause of performance degradation and premature component failure in high-power systems.

Thermal Stability Across Temperatures: HA80 Aluminum PCB maintains consistent thermal performance across a wide operating temperature range, from extreme cold to elevated heat. This stability is critical for outdoor applications, automotive underhood systems, and industrial environments where temperature fluctuations are common.

Electrical Performance and Signal Integrity

Low Electrical Loss: The dielectric layer’s low dissipation factor and stable dielectric constant reduce signal attenuation, making HA80 Aluminum PCB suitable for high-frequency applications such as sensor interfaces and communication modules.

High Insulation Strength: The dielectric material maintains robust electrical insulation even under prolonged use, preventing leakage currents and ensuring safe operation in high-voltage scenarios, including power inverters and industrial control systems.

Mechanical Durability

Vibration and Impact Resistance: The aluminum substrate and reinforced dielectric layer endow HA80 Aluminum PCB with exceptional resistance to vibration and mechanical impact. This durability makes it suitable for rugged environments such as industrial machinery, automotive chassis, and aerospace equipment.

Resistance to Environmental Stress: HA80 Aluminum PCB is engineered to withstand exposure to moisture, dust, and chemical agents, thanks to protective surface treatments and corrosion-resistant materials. This resilience extends service life in outdoor and harsh industrial settings.

Industry Applications of HA80 Aluminum PCB

HA80 Aluminum PCB’s unique blend of thermal, electrical, and mechanical properties makes it a preferred choice in diverse high-demand sectors:

Automotive Electronics

Power Electronics: In electric and hybrid vehicles, HA80 Aluminum PCB manages heat in battery management systems (BMS), inverters, and motor controllers. Its thermal efficiency prevents overheating in power-dense components, ensuring safe and reliable operation.

Vehicle Lighting Systems: HA80 Aluminum PCB supports high-output LED headlights, taillights, and interior lighting, dissipating heat to maintain brightness consistency and extend LED lifespan. Its vibration resistance ensures performance in vehicle-mounted applications.

Industrial Automation

Motor Drives and Controls: Industrial motor drives and programmable logic controllers (PLCs) rely on HA80 Aluminum PCB to dissipate heat from IGBT modules and power semiconductors. This thermal management ensures uninterrupted operation in factories with high ambient temperatures.

Sensor and Actuator Modules: In industrial IoT (IIoT) systems, HA80 Aluminum PCB provides stable electrical performance for sensors and actuators, withstanding dust, moisture, and temperature fluctuations in manufacturing environments.

LED Lighting and Renewable Energy

High-Power LED Fixtures: HA80 Aluminum PCB is widely used in commercial, industrial, and outdoor LED lighting (e.g., streetlights, stadium lighting), where efficient heat dissipation prevents lumen depreciation and extends fixture life.

Renewable Energy Equipment: Solar inverters and wind turbine control systems leverage HA80 Aluminum PCB for thermal management in power conversion components, ensuring efficiency in outdoor installations exposed to varying weather conditions.

Manufacturing and Quality Assurance for HA80 Aluminum PCB

The production of HA80 Aluminum PCB adheres to stringent manufacturing standards and quality control protocols to ensure consistency and reliability:

Precision Manufacturing Processes

Controlled Lamination: The aluminum substrate, dielectric layer, and copper foil are bonded under precisely controlled temperature and pressure conditions to eliminate voids and ensure uniform adhesion. This step is critical for minimizing thermal resistance at layer interfaces.

High-Accuracy Etching: Advanced etching techniques (laser or chemical) create precise circuit traces and vias, ensuring dimensional accuracy and impedance consistency—key for high-frequency and high-density designs.

Surface Treatment: Protective coatings (e.g., solder masks, conformal coatings) are applied to enhance corrosion resistance, solderability, and environmental protection, tailored to application-specific requirements.

Rigorous Quality Validation

Thermal Performance Testing: HA80 Aluminum PCB undergoes thermal mapping and thermal resistance analysis to verify heat dissipation efficiency under simulated operating conditions.

Electrical Testing: Insulation resistance, continuity checks, and high-potential (hipot) tests validate electrical integrity, ensuring no short circuits or signal degradation.

Environmental Stress Testing: Samples are subjected to thermal cycling, vibration, and humidity exposure to simulate real-world conditions, ensuring durability in harsh environments.

Advantages Over Conventional PCB Materials

HA80 Aluminum PCB outperforms traditional FR-4 PCBs and standard aluminum PCBs in key metrics:

Enhanced Thermal Conductivity: Compared to FR-4, HA80 Aluminum PCB’s aluminum substrate and optimized dielectric layer provide superior heat dissipation, making it ideal for high-power components that generate significant heat.

Improved Mechanical Durability: HA80’s aluminum core offers greater rigidity and vibration resistance than flexible PCBs or thin FR-4 boards, reducing the risk of mechanical failure in rugged applications.

Stable Electrical Properties: The dielectric layer’s consistent performance across temperature ranges ensures reliable signal transmission, outperforming materials prone to electrical property degradation under heat.

Future Trends and Application Expansion

As industries continue to push for higher power densities and compact designs, HA80 Aluminum PCB is poised to play a growing role in emerging technologies:

Automotive Electrification: With the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), HA80 Aluminum PCB will support thermal management in next-generation power electronics and sensor modules.

Smart Industrial Systems: In Industry 4.0, HA80 Aluminum PCB will enable more compact, efficient motor drives and sensor networks, supporting real-time data collection and automation.

Sustainable Lighting: As LED technology advances toward higher efficiency, HA80 Aluminum PCB will remain critical for thermal management in energy-efficient lighting solutions.

Conclusion

HA80 Aluminum PCB represents a specialized solution for power-dense, high-reliability electronics, combining thermal efficiency, electrical stability, and mechanical durability in a single platform. Its advanced material architecture and rigorous manufacturing standards make it a trusted choice for automotive, industrial, and LED lighting applications, where performance and longevity are paramount. As industries continue to demand more from electronic systems, HA80 Aluminum PCB will remain a key enabler, providing engineers with a versatile tool to address the challenges of modern electronics.

Keywords: HA80 Aluminum PCB, thermal management, high-power electronics, automotive applications, industrial automation, LED lighting, PCB reliability.

This article provides a comprehensive, technically focused overview of HA80 Aluminum PCB, emphasizing its unique attributes and industry relevance while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB