-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 08. 2025, 13:00:48

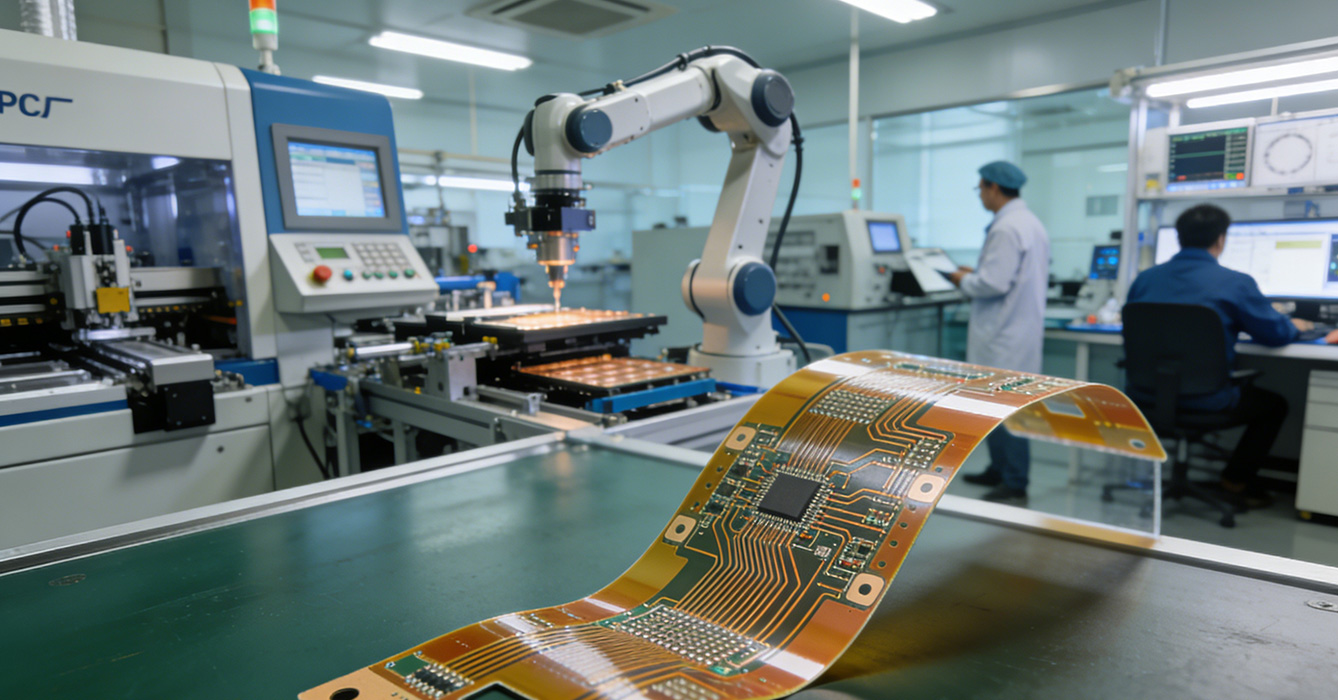

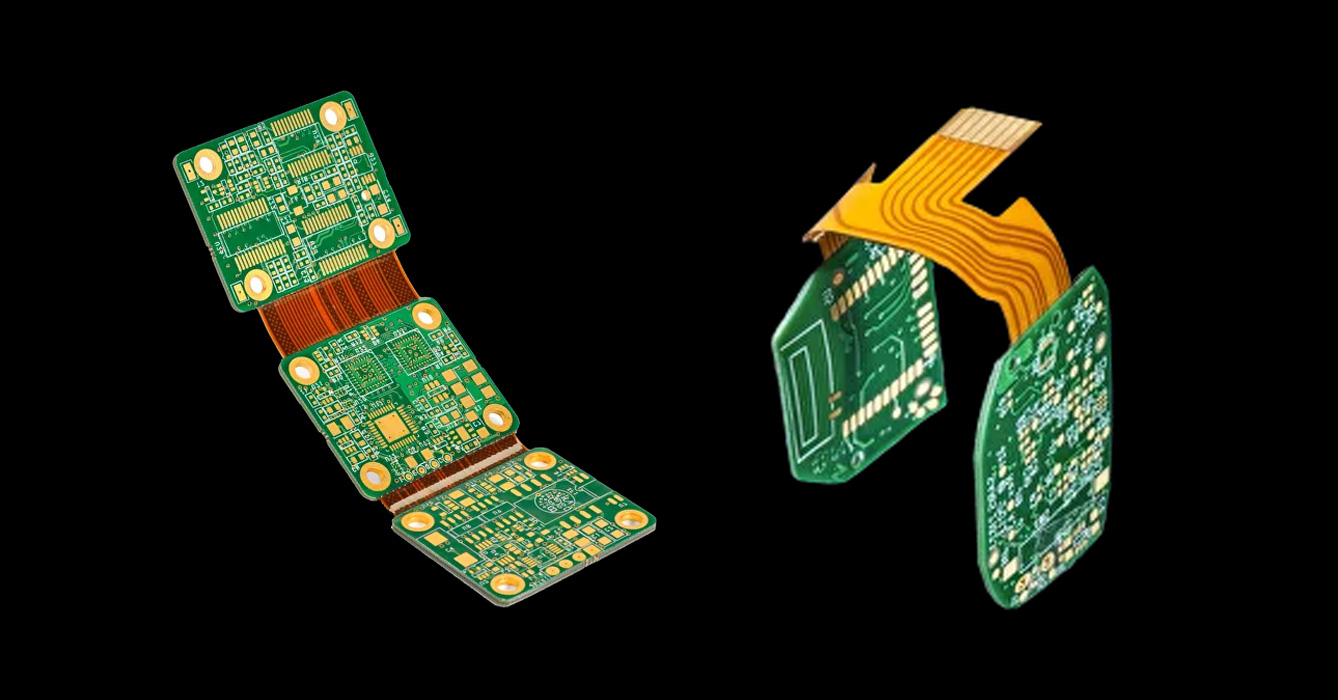

As high brightness (HB) LED lighting gains traction in high-demand scenarios—from stadium illumination, high-bay industrial lighting to automotive high-beam headlights and stage lighting—the role of a professional High Brightness LED FPC Supplier has become indispensable. Specializing in flexible printed circuits (FPCs) engineered for high-power, high-lumen LED systems, these suppliers bridge the gap between HB LED’s luminous performance requirements and the technical challenges of power handling, heat dissipation, and light uniformity. Unlike generic LED FPC suppliers, a High Brightness LED FPC Supplier focuses on integrating high-current compatibility, thermal management, and precision circuit design to ensure FPCs can support HB LEDs’ full luminous potential while maintaining long-term reliability. For LED lighting brands aiming to compete in high-brightness segments, partnering with a reputable High Brightness LED FPC Supplier is critical to delivering high-performance, market-leading products.

High brightness LEDs operate at higher power densities, posing unique technical challenges that specialized High Brightness LED FPC Suppliers are tailored to address:

- High-Current Compatibility & Low Impedance Design: HB LEDs require stable high-current supply to achieve peak brightness. Top suppliers design FPCs with low-impedance conductive materials (e.g., high-purity copper foils) and optimized circuit routing—such as widened trace widths and minimized current paths—to reduce power loss and voltage drop. This ensures consistent high-current delivery to each LED chip, avoiding brightness dips or uneven luminous output.

- Mitigating Light Degradation & Thermal Stress: High power operation generates significant heat, which accelerates LED light degradation (lumen depreciation) and FPC material aging. High Brightness LED FPC Suppliers integrate thermal management into FPC design, using high-thermal-conductivity substrates (e.g., aluminum-based flexible substrates) and heat-dissipating coverlay materials. They also optimize FPC layout to distribute heat evenly, preventing hotspots that damage LEDs or FPC circuits.

- Ensuring Circuit Stability Under High Power: High-current operation increases the risk of circuit overheating, short circuits, and insulation breakdown. Suppliers adopt high-temperature-resistant, flame-retardant FPC materials (compliant with UL 94 V-0 standards) and implement reinforced insulation structures at key nodes. Precision manufacturing processes—such as controlled impedance routing and strict solder joint quality control—further enhance circuit stability under high-power loads.

A professional High Brightness LED FPC Supplier goes beyond basic power handling, focusing on optimizing FPCs to maximize HB LED luminous efficiency:

- Uniform Light Distribution Design: Consistent brightness across the LED array is critical for high-brightness lighting. Suppliers use ultra-precise circuit etching technologies to ensure uniform trace resistance, enabling balanced current distribution to every LED chip. They also collaborate with lighting designers to optimize FPC layout, matching LED placement to achieve seamless light mixing and eliminate dark spots.

- Impedance Matching for Power Efficiency: Poor impedance matching wastes power and reduces luminous efficiency. High Brightness LED FPC Suppliers use advanced EDA (Electronic Design Automation) tools to simulate and optimize FPC impedance, ensuring efficient power transfer from the driver to the LEDs. This minimizes power loss, allowing more electrical energy to be converted into visible light.

- UV & Environmental Resistance for Outdoor Bright Lighting: Many high-brightness applications (e.g., outdoor high-bay lighting, stadium lights) are exposed to UV radiation and harsh weather. Suppliers treat FPC surfaces with UV-resistant coatings and use weatherproof materials to prevent material degradation, ensuring consistent luminous performance and FPC reliability over long-term outdoor use.

High Brightness LED FPC Suppliers tailor solutions to the unique requirements of different high-brightness lighting segments:

- Industrial High-Bay & Stadium Lighting: Supplies high-current FPCs with enhanced heat dissipation capabilities for large-area, high-lumen lighting systems. These FPCs support dense LED arrays (hundreds of HB LEDs per module) and are designed for easy integration with heat sinks, ensuring stable operation in 24/7 industrial or sports venue environments.

- Automotive High-Brightness Lighting: Delivers automotive-grade FPCs for high-beam headlights, fog lights, and daytime running lights (DRLs) with HB LEDs. The FPCs comply with IATF 16949 standards, resisting high temperatures (up to 150°C+), vibration, and automotive fluids while ensuring precise light beam control.

- Stage & Entertainment Lighting: Provides flexible FPCs for dynamic stage lighting (e.g., moving head lights, LED strips) that require both high brightness and structural flexibility. These FPCs support rapid dimming and color switching functions, with low latency circuit design to match the real-time performance needs of entertainment lighting.

- High-Definition Display Backlighting: Develops ultra-thin FPCs for high-brightness LCD/mini-LED backlights (e.g., large-format commercial displays, automotive infotainment screens). The FPCs enable dense LED placement for high contrast ratios, with uniform current distribution to ensure consistent brightness across the display surface.

To ensure performance in high-power scenarios, High Brightness LED FPC Suppliers implement rigorous testing and comply with strict industry standards:

- High-Power Reliability Testing: Key tests include long-term high-current aging testing (to simulate continuous operation), thermal cycling testing (to validate heat resistance), and lumen maintenance monitoring (to ensure minimal light degradation). These tests confirm that FPCs support HB LEDs’ lifespan requirements (typically 50,000+ hours).

- Global Industry Compliance: Suppliers comply with international standards such as IPC-6012/2221 (FPC quality), RoHS/REACH (environmental protection), and lighting-specific certifications (UL 8750, CE). For automotive applications, they meet additional AEC-Q200 standards for passive components, ensuring compliance with automotive safety and reliability requirements.

In conclusion, a High Brightness LED FPC Supplier is a critical enabler of high-performance HB LED lighting, leveraging specialized high-current design, thermal management, and luminous efficiency optimization to unlock the full potential of high-brightness LEDs. Their ability to tailor solutions to diverse high-power applications and ensure long-term reliability addresses the core pain points of HB LED lighting design. As the demand for high-lumen, energy-efficient lighting continues to grow across industrial, automotive, and entertainment sectors, partnering with a professional High Brightness LED FPC Supplier will remain a strategic choice for brands seeking to gain a competitive edge in the high-brightness LED market.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB