-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 17. 2025, 10:25:32

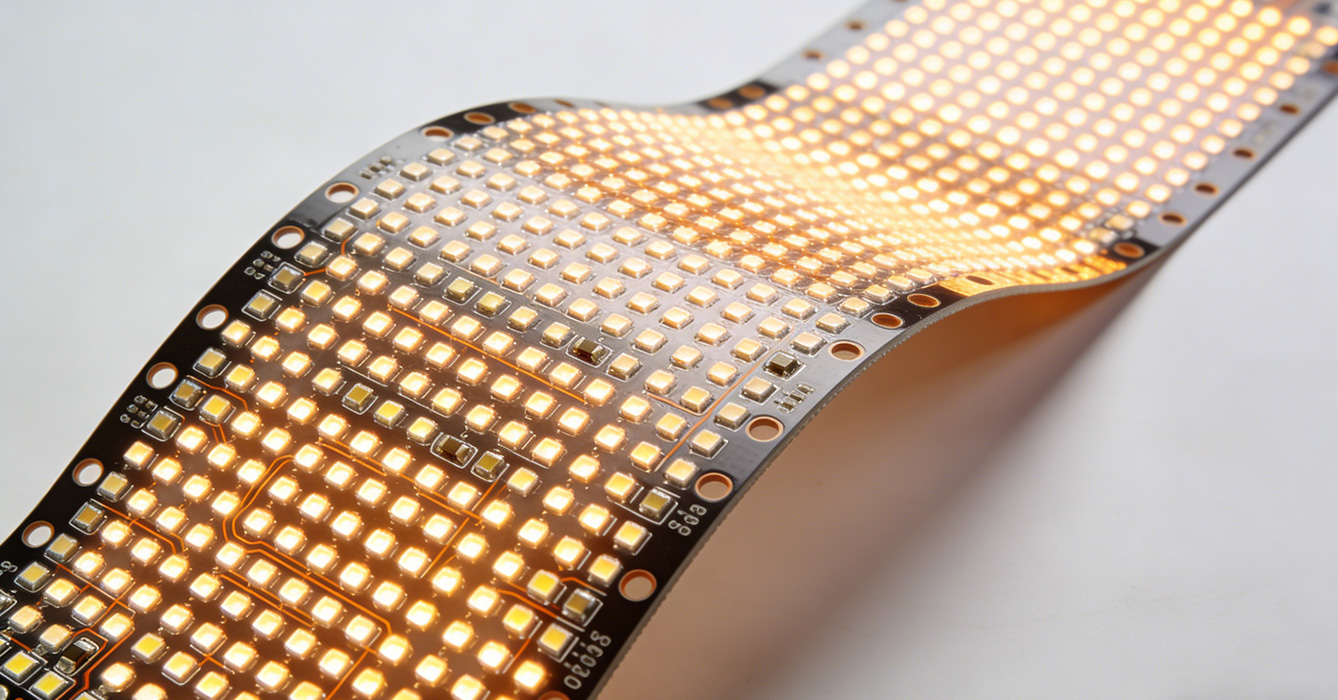

As high brightness LED (HBLED) technology penetrates commercial lighting, stage illumination, and high-definition display sectors, the demand for High Brightness LED Flex PCB has escalated rapidly. This specialized circuit solution integrates light efficiency enhancement, precise thermal management, and advanced packaging technologies, addressing the core challenges of HBLED systems—such as heat accumulation and light loss—while leveraging the flexibility and compactness of flexible PCBs. Unlike standard LED flex PCBs designed for general illumination, High Brightness LED Flex PCB is engineered to maximize luminous efficiency, ensure long-term stability under high-power operation, and enable creative lighting designs. For lighting manufacturers, adopting high-performance High Brightness LED Flex PCB is pivotal to delivering high-lumen, energy-efficient lighting solutions and expanding into premium market segments.

The performance of High Brightness LED Flex PCB relies on the seamless synergy between light efficiency optimization and thermal management, as excessive heat directly impairs luminous efficiency and lifespan:

- Thermally Enhanced Flexible Substrates: To address heat accumulation in high-power HBLEDs, High Brightness LED Flex PCB adopts metal-clad flexible substrates (e.g., aluminum-based or copper-based polyimide) instead of traditional pure PI substrates. These substrates combine excellent flexibility with high thermal conductivity, efficiently transferring heat from LED chips to the ambient environment. The integrated thermal pathway reduces the junction temperature of LEDs, minimizing light decay and extending the service life of lighting systems. This design is particularly critical for high-density HBLED configurations such as linear high-brightness strips.

- High-Reflectivity Material & Surface Treatment: Light loss is a major concern for high brightness applications. High Brightness LED Flex PCB utilizes nano-ceramic filled PI substrates with a surface reflectivity of over 95%, maximizing the utilization of emitted light by minimizing absorption. Additionally, the circuit traces and solder pads undergo specialized surface treatments (e.g., high-reflectivity silver plating or organic coatings), reducing light blocking and ensuring uniform light distribution. This optimization significantly enhances the overall light efficiency of HBLED systems without increasing power consumption.

High Brightness LED Flex PCB fully leverages Chip-on-Board (COB) packaging technology to unlock the full potential of HBLEDs, overcoming the limitations of traditional SMD packaging:

- COB Integration for Dense Illumination: COB packaging directly bonds bare HBLED chips to the flexible substrate, eliminating the need for individual LED packages. This enables ultra-high-density chip placement, creating a uniform surface light source that delivers high brightness without visible pixelation. High Brightness LED Flex PCB with COB packaging also simplifies the manufacturing process by reducing assembly steps, improving production yield, and lowering overall costs. It is ideally suited for high-brightness applications such as stage lighting and large-area commercial displays.

- Encapsulation Optimization for Light Efficiency: The encapsulation material of COB-integrated High Brightness LED Flex PCB is carefully selected for high light transmittance and UV resistance. Silicone-based encapsulants with optimized refractive indices are used to minimize light refraction loss, ensuring maximum light output. The encapsulation process also provides mechanical protection for bare chips, enhancing the reliability of High Brightness LED Flex PCB in harsh operating environments such as outdoor stadiums.

Advanced manufacturing processes ensure the consistency and reliability of High Brightness LED Flex PCB, critical for mass-produced high-brightness lighting systems:

- Micron-Level Precision Etching: High Brightness LED Flex PCB requires ultra-fine circuit traces to support high-density HBLED integration. Precision etching technology achieves trace widths and spacings of less than 50μm, ensuring stable current distribution across all LED chips. This precise circuit design prevents local overheating and ensures uniform brightness, a key requirement for high-end lighting applications.

- Roll-to-Roll (R2R) Production for Scalability: For large-volume high-brightness LED flex strips, R2R continuous production technology is adopted. This process enables automated, high-speed manufacturing, reducing material waste and ensuring consistent product quality. R2R production also supports the fabrication of "infinitely long" High Brightness LED Flex PCB, meeting the requirements of large-scale lighting projects such as architectural facade lighting and sports venue illumination.

High Brightness LED Flex PCB enables innovative solutions across diverse high-brightness lighting applications, leveraging its flexibility and high-performance characteristics:

- Stage & Entertainment Lighting: In stage lighting and concert venues, High Brightness LED Flex PCB’s flexibility allows it to be shaped into complex forms (e.g., curved light bars, custom logos), creating dynamic and immersive lighting effects. Its high brightness and uniform light output ensure clear illumination even in large spaces, while efficient thermal management supports long-hour continuous operation.

- Commercial & Architectural Lighting: For high-end retail stores, museums, and architectural facade lighting, High Brightness LED Flex PCB with COB packaging delivers high-intensity, uniform light that enhances product displays and architectural details. Its thin and flexible design enables seamless integration into hidden light slots and curved surfaces, maintaining the aesthetic integrity of the space.

- High-Definition LED Displays: In mini/micro LED displays and large-scale outdoor billboards, High Brightness LED Flex PCB provides the high-density interconnection and high brightness required for clear visibility in bright daylight. Its flexibility supports the development of curved and foldable high-definition displays, expanding the application boundaries of LED display technology.

The development of High Brightness LED Flex PCB is evolving toward smart functionality and enhanced energy efficiency to meet the growing demand for sustainable lighting:

- Smart Dimming & Control Integration: Future High Brightness LED Flex PCB will integrate driver ICs and sensors directly into the flexible substrate, enabling intelligent dimming and color temperature adjustment. This smart functionality supports adaptive lighting systems that respond to ambient light conditions and user preferences, enhancing energy efficiency and user experience.

- Energy Efficiency Optimization: Research is focused on developing low-power consumption High Brightness LED Flex PCB by optimizing substrate materials and circuit designs. The integration of energy-harvesting technologies (e.g., solar-assisted power supply) is also being explored, further reducing the environmental impact of high-brightness lighting systems.

- Cost Reduction for Mass Adoption: Advancements in automated COB packaging and R2R production technologies will reduce the manufacturing cost of High Brightness LED Flex PCB, making high-brightness flexible lighting accessible to mainstream applications such as residential high-brightness strips and automotive high-brightness ambient lighting.

In conclusion, High Brightness LED Flex PCB is a critical enabler of high-performance, flexible lighting solutions, combining thermal management excellence, light efficiency optimization, and advanced COB packaging. Its unique capabilities support innovation across stage lighting, commercial displays, and architectural illumination sectors. As the industry moves toward smart and sustainable lighting, High Brightness LED Flex PCB will play an increasingly vital role in shaping the future of high-brightness LED applications, delivering both performance and environmental benefits.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB