-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 20. 2025, 15:56:35

In the rapidly evolving world of electronics, high-density flex PCB assembly has become a critical component in modern technology. As devices shrink and become more complex, the need for compact, reliable, and flexible printed circuit boards (PCBs) has never been greater. Let's delve into the world of high-density flex PCBs, exploring their fabrication, assembly services, and why they are essential in today's tech-driven landscape.

PCB fabrication is the process of creating the physical board that will hold and connect the electronic components. It involves several steps that transform a design into a functional product. Here's a breakdown of the key stages:

The journey begins with the design of the PCB, which is usually done using specialized software. Engineers create a schematic that maps out the electronic circuit, ensuring all components are correctly placed and connected.

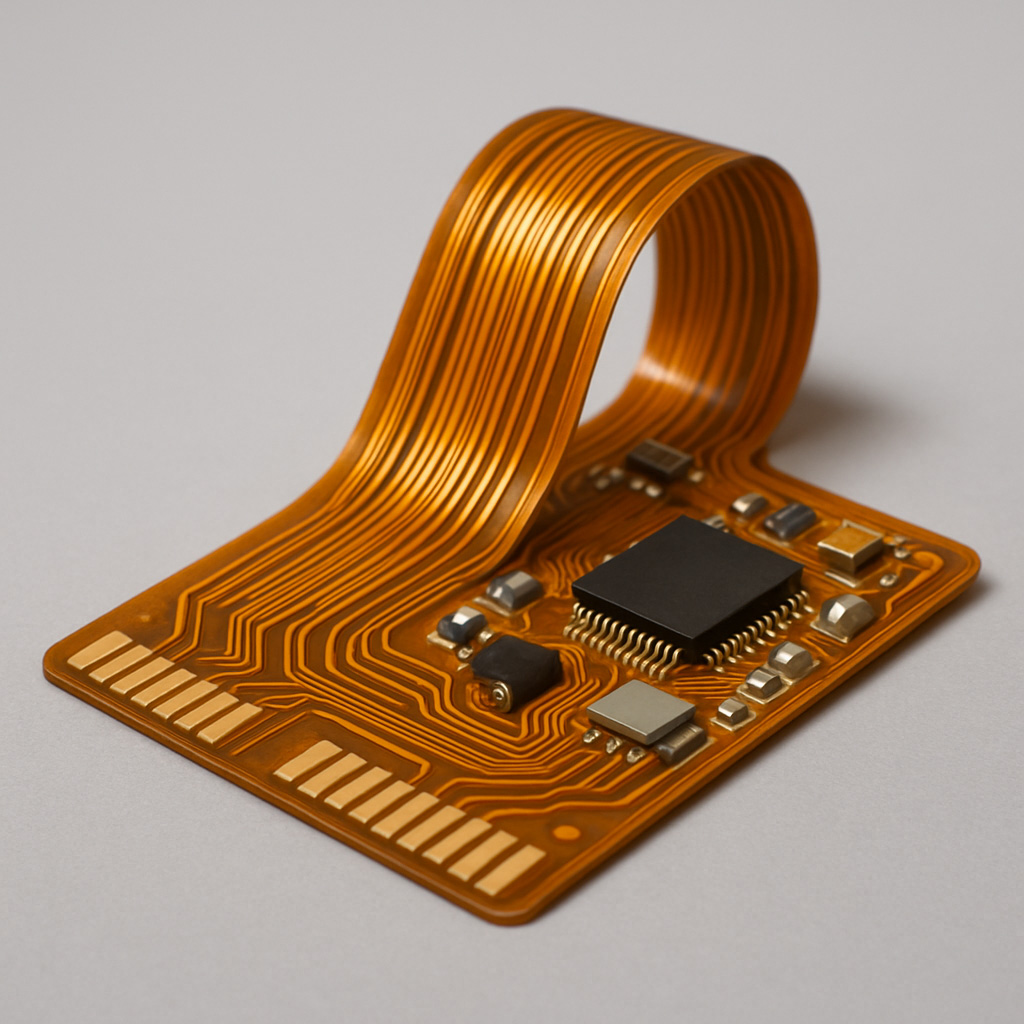

Choosing the right materials is crucial for high-density flex PCBs. The flexibility of the board is achieved through the use of flexible substrates, such as polyimide, which allows the board to bend and flex without breaking. This flexibility is essential for applications where space is limited or where the board needs to conform to a specific shape.

High-density PCBs often require multiple layers to accommodate the complex circuitry. The layers are stacked and bonded together, with vias (small holes) drilled to allow electrical connections between the layers.

Once the layers are stacked, the board undergoes an etching process to remove excess copper, leaving behind the desired circuit pattern. Plating involves adding a thin layer of metal to the surface and through the vias, which improves electrical conductivity and component adhesion.

A solder mask is applied to protect the copper traces from oxidation and short-circuiting. The silkscreen is then added, providing labels and identifiers for components, making assembly and maintenance easier.

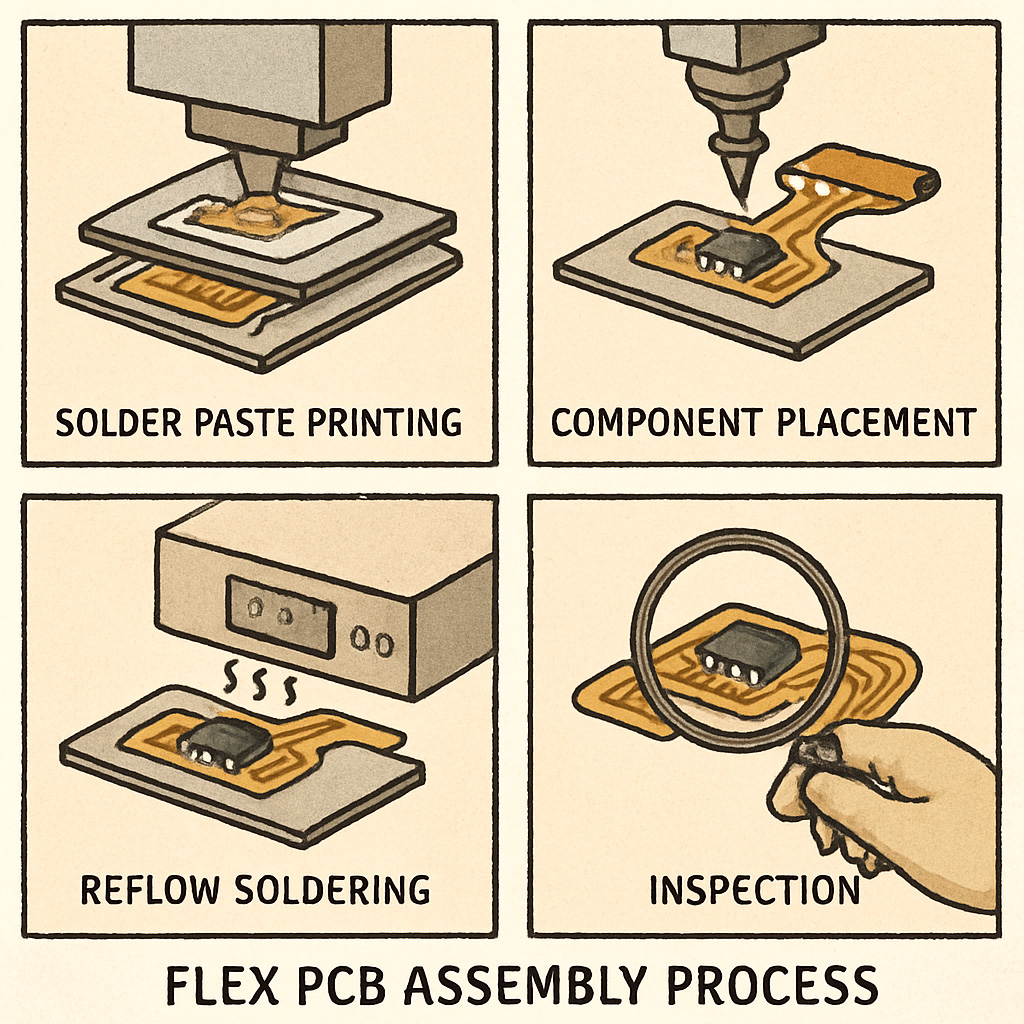

Once the PCB is fabricated, it moves on to the assembly phase, where the actual electronic components are placed and soldered onto the board. Here's how PCB assembly services bring designs to life:

Using automated machinery, components are precisely placed onto the PCB according to the design specifications. High-density flex PCBs require meticulous attention to detail due to their compact nature.

Soldering is the process of securing components to the board. Techniques such as reflow soldering and wave soldering are commonly used. Reflow soldering involves passing the board through an oven, melting the solder to create strong electrical connections.

Quality control is a critical step in PCB assembly. Each board undergoes rigorous testing, including visual inspections and automated optical inspections (AOI), to ensure that it functions correctly and meets industry standards.

Before shipping, assembled boards are subjected to final testing to verify their functionality. This includes electrical testing to check for shorts, opens, and other defects that could affect performance.

High-density flex PCB assembly offers several advantages that make it indispensable for modern electronics:

One of the primary benefits of high-density flex PCBs is their ability to fit into compact spaces. Their flexible nature allows them to be folded or bent, making them ideal for use in small devices like smartphones, wearable technology, and medical implants.

Flex PCBs are designed to withstand harsh conditions. Their flexibility and resilience make them less prone to damage from vibrations and physical stress, which is crucial in automotive and aerospace applications.

The ability to integrate multiple functions into a single board leads to enhanced performance. High-density flex PCBs support high-speed signal transmission and reduce the need for interconnects, resulting in better signal integrity and reduced electromagnetic interference (EMI).

While the initial investment in designing and manufacturing high-density flex PCBs may be higher, the long-term benefits outweigh the costs. Their reliability and reduced need for repairs or replacements make them a cost-effective solution for many industries.

High-density flex PCBs are found in various industries, each benefiting from their unique properties:

In consumer electronics, such as smartphones and tablets, high-density flex PCBs allow for sleek designs and improved functionality. They enable manufacturers to pack more features into smaller devices without compromising performance.

Medical devices, including pacemakers and hearing aids, rely on high-density flex PCBs for their small size and reliability. These boards can be shaped to fit within the human body, providing critical functionality in life-saving technologies.

In the automotive industry, flex PCBs are used in advanced driver-assistance systems (ADAS), infotainment systems, and lighting. Their durability and ability to withstand extreme temperatures make them ideal for automotive applications.

Aerospace and defense industries use high-density flex PCBs for their lightweight and robust nature. They are employed in navigation systems, communication devices, and avionics, where reliability is paramount.

When it comes to high-density flex PCB assembly, selecting the right partner is crucial. Here are some factors to consider:

Choose a partner with a proven track record in high-density flex PCB assembly. Their expertise will ensure that your boards are manufactured and assembled to the highest standards.

Look for a partner with state-of-the-art facilities and equipment. Advanced machinery and technology are essential for producing high-quality, reliable PCBs.

Ensure that your partner has a robust quality assurance process in place. This includes certifications such as ISO 9001 and IPC standards, which guarantee that the products meet industry requirements.

Good customer support is essential for a successful partnership. Choose a partner who offers excellent communication and is responsive to your needs throughout the project.

High-density flex PCB assembly plays a vital role in the advancement of modern electronics. With their space-saving design, enhanced durability, and improved performance, these PCBs are essential for industries ranging from consumer electronics to aerospace. By understanding the fabrication and assembly process and choosing the right partner, you can harness the full potential of high-density flex PCBs for your next project.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB