-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 27. 2025, 13:45:52

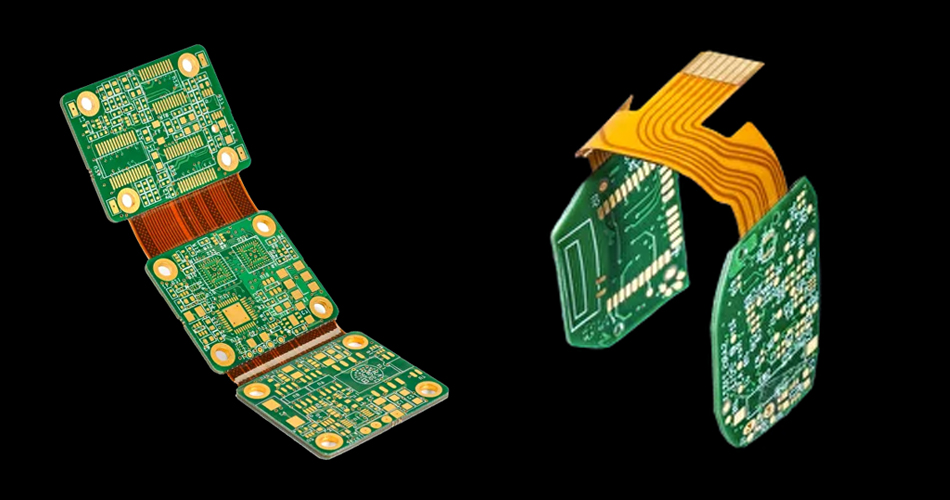

In the era of miniaturized, high-performance electronics, the demand for flexible printed circuits (FPCs) with exceptional precision has never been greater. The High Precision FPC Fabrication Process stands as a cornerstone technology, enabling the production of FPCs that meet the strict tolerances, signal integrity, and mechanical reliability required for cutting-edge devices. Unlike standard FPC fabrication, which prioritizes cost or speed, this specialized process focuses on meticulous control over every manufacturing step—from material selection to final assembly—delivering circuits that perform flawlessly in applications where even minor deviations can cause system failure. For industries ranging from aerospace to medical devices and consumer electronics, this process is the backbone of innovation, enabling designs that push the boundaries of what’s possible with flexible electronics.

At the core of the High Precision FPC Fabrication Process are four interconnected pillars that ensure exceptional quality and performance:

Meticulous Material Selection: Precision starts with choosing high-grade substrates (such as polyimide) and conductive materials that offer consistent electrical performance, mechanical flexibility, and resistance to environmental stress (temperature, humidity, chemicals). These materials are rigorously tested to ensure they meet strict specifications, providing a stable foundation for precise circuit formation.

Advanced Circuit Patterning: Utilizing state-of-the-art lithography and etching technologies, the process creates ultra-fine circuit traces and pads with minimal variation. High-precision equipment ensures tight line-width and line-spacing tolerances, critical for maintaining signal integrity in high-frequency or dense circuit designs. Unlike standard processes, which may compromise on detail for efficiency, this step prioritizes accuracy to prevent cross-talk or electrical interference.

Precision Lamination & Bonding: For multi-layer or rigid-flex FPCs, the lamination process is executed with exacting pressure and temperature control. This ensures uniform adhesion between layers, eliminating air bubbles or delamination risks that can degrade performance over time. The bonding of components (such as connectors or sensors) is also performed with precision, ensuring mechanical stability and reliable electrical contact.

Rigorous Quality Control: Every stage of the process is monitored by advanced inspection tools—including automated optical inspection (AOI) and X-ray testing—to detect defects early. This proactive quality control ensures that even microscopic flaws (such as trace breaks or misalignments) are identified and corrected before the FPC moves to the next stage, minimizing waste and ensuring consistent performance.

The demand for High Precision FPC Fabrication Process is driven by the evolving needs of advanced electronics, where precision directly impacts performance, reliability, and safety:

Signal Integrity for High-Frequency Devices: In applications like 5G-enabled devices, aerospace avionics, and industrial sensors, FPCs must transmit high-frequency signals without degradation. Precise circuit patterning and material control reduce signal loss and interference, ensuring reliable data transfer.

Miniaturization & Density: As devices become smaller and more complex, FPCs must fit into tighter spaces while accommodating more components. The High Precision FPC Fabrication Process enables dense circuit layouts with ultra-fine traces, supporting the miniaturization of wearables, medical implants, and portable electronics.

Mechanical Reliability in Dynamic Environments: Flexible electronics often operate in applications where they bend, twist, or vibrate (e.g., robotic arms, foldable phones, automotive components). Precision fabrication ensures that circuit traces and connections can withstand repeated mechanical stress without failure, extending product lifespan.

Safety-Critical Performance: In medical devices (e.g., pacemakers, diagnostic tools) and aerospace systems, FPC failures can have life-threatening consequences. The High Precision FPC Fabrication Process delivers the consistency and reliability required for these safety-critical applications, complying with strict industry standards.

The High Precision FPC Fabrication Process is indispensable across sectors where precision and reliability are non-negotiable:

Medical Devices: Powers implantable sensors, minimally invasive surgical tools, and portable diagnostic equipment. The process ensures FPCs meet biocompatibility standards and perform reliably in the human body or sterile medical environments.

Aerospace & Defense: Enables lightweight, high-performance FPCs for avionics systems, satellite components, and military communication devices. Precision fabrication ensures resistance to extreme temperatures, radiation, and vibration.

Consumer Electronics: Supports foldable smartphones, smartwatches, and wireless earbuds. The process delivers FPCs that combine flexibility with durability, surviving thousands of folds while maintaining electrical performance.

Industrial IoT & Automation: Powers high-precision sensors, robotic actuators, and smart factory control systems. Precision FPCs ensure accurate data collection and reliable operation in harsh industrial environments.

Automotive Electronics: Critical for ADAS sensors, in-vehicle infotainment, and EV powertrain components. The process delivers FPCs that withstand under-hood heat, vibration, and electrical stress while maintaining signal integrity.

As electronics continue to evolve toward higher frequencies, smaller form factors, and more demanding environments, the High Precision FPC Fabrication Process will advance in tandem. Future innovations may include the integration of advanced materials (such as carbon nanotubes) for enhanced performance, AI-driven quality control for real-time defect detection, and hybrid processes that combine flexibility with rigid structural elements for even more versatile designs. For manufacturers and engineers, investing in this precision process is not just a choice—it’s a necessity to stay competitive in a market where performance and reliability are paramount.

In conclusion, the High Precision FPC Fabrication Process is a specialized technology that enables the development of advanced flexible electronics. By prioritizing material quality, precise manufacturing steps, and rigorous quality control, it delivers FPCs that meet the strict demands of modern applications. From life-saving medical devices to cutting-edge consumer gadgets, this process is a critical enabler of innovation, ensuring that flexible electronics perform reliably, efficiently, and safely. As the electronics industry continues to push the boundaries of precision and miniaturization, the High Precision FPC Fabrication Process will remain an essential tool for turning bold design concepts into reality.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB