-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 29. 2025, 16:15:54

In the competitive landscape of high-end electronics, product reliability and performance consistency have become the core criteria for market success. Behind every trusted electronic device lies the solid support of a High Quality Flex FPCB Manufacturer. Unlike ordinary flex FPCB manufacturers that prioritize cost over quality, a High Quality Flex FPCB Manufacturer is committed to delivering flexible printed circuit boards that meet stringent quality standards, with stable electrical performance, excellent durability, and consistent batch-to-batch quality. From premium consumer electronics to industrial control systems and automotive electronics, these manufacturers provide the foundational components that ensure electronic products operate reliably in diverse scenarios. Their focus on quality runs through every link of production, making them indispensable strategic partners for brands pursuing long-term market competitiveness.

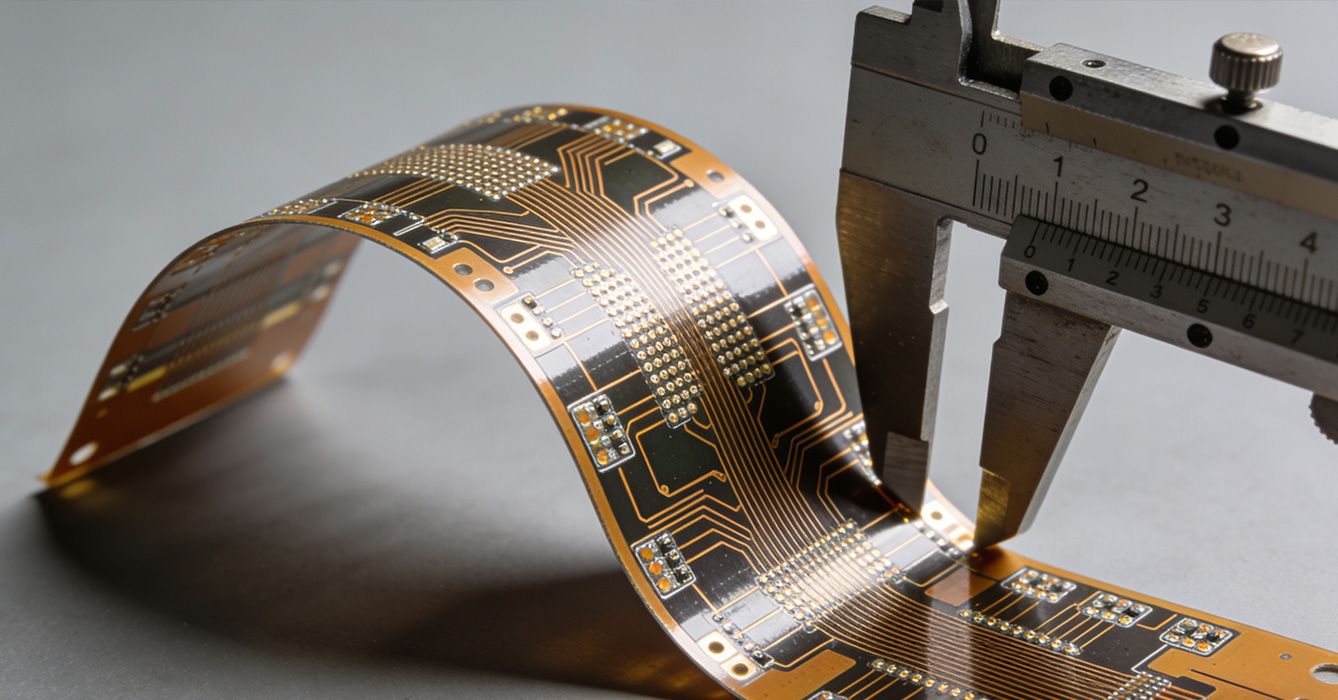

A standout High Quality Flex FPCB Manufacturer distinguishes itself through three core traits that underpin its quality commitment. Firstly, it implements a rigorous full-cycle quality management system. From the selection of raw materials, where only high-grade substrates and components that meet international standards are used, to every production process—including circuit patterning, lamination, and etching—strict quality checks are implemented to eliminate defects. This full-cycle control ensures that each flex FPCB meets the predefined quality benchmarks before leaving the factory.

Secondly, it possesses advanced production technology and equipment. High-quality flex FPCB production relies on state-of-the-art manufacturing technologies, such as precision laser drilling, automated soldering, and high-resolution optical inspection. These advanced tools not only improve production accuracy but also reduce human errors, laying a solid foundation for consistent quality. Additionally, a professional High Quality Flex FPCB Manufacturer invests in continuous technological upgrading to keep pace with the evolving quality requirements of high-end electronics, such as higher signal integrity and better environmental resistance.

Thirdly, it holds authoritative international quality certifications. Certifications such as ISO 9001 (quality management system), IATF 16949 (automotive industry quality standard), and RoHS (environmental protection standard) are not just labels for these manufacturers but tangible proof of their quality management capabilities. Complying with these international standards ensures that their flex FPCBs can meet the quality and regulatory requirements of global markets, facilitating the global expansion of their client’s products.

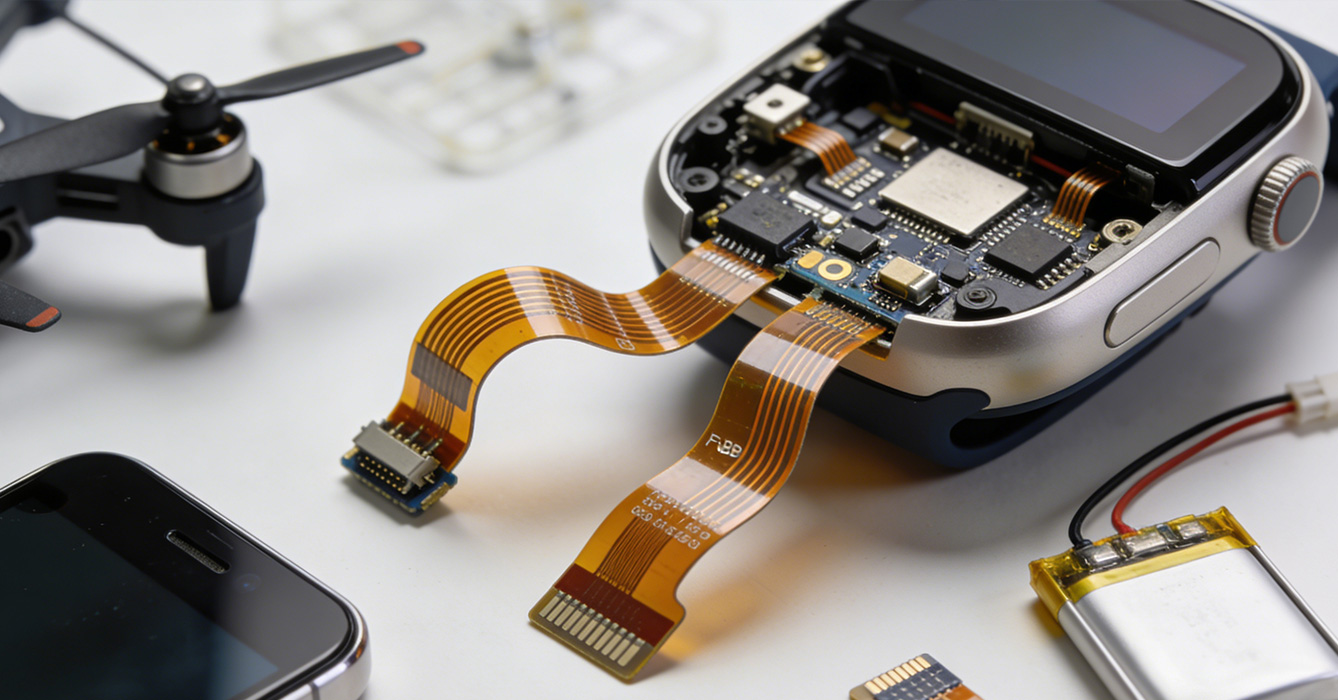

The high-quality flex FPCBs supplied by a High Quality Flex FPCB Manufacturer have been widely applied in various high-end electronic sectors, driving the improvement of product reliability. In the premium consumer electronics sector, they are the core components of foldable smartphones, high-end smartwatches, and wireless noise-canceling earbuds. These products require flex FPCBs with excellent bending resistance and stable signal transmission to ensure long-term reliable use under frequent user operations—requirements that only a High Quality Flex FPCB Manufacturer can fulfill.

In the automotive electronics sector, High Quality Flex FPCB Manufacturer play a crucial role in supplying components for advanced driver-assistance systems (ADAS), in-vehicle infotainment systems, and electric vehicle (EV) powertrain components. Automotive electronics operate in harsh environments with extreme temperatures, vibrations, and electromagnetic interference, so flex FPCBs must have superior environmental resistance and reliability. The high-quality products from these manufacturers ensure the safe and stable operation of automotive electronic systems, which is critical for driving safety.

The industrial control sector also benefits significantly from High Quality Flex FPCB Manufacturer. Industrial control systems, such as programmable logic controllers (PLCs) and sensor modules, require flex FPCBs that can operate stably for long periods in industrial environments with high humidity, dust, and voltage fluctuations. The high-quality flex FPCBs ensure the continuous and reliable operation of these systems, reducing downtime and improving industrial production efficiency.

Choosing the right High Quality Flex FPCB Manufacturer is critical to ensuring the quality and reliability of end products. Firstly, verify the manufacturer’s quality management system and certifications. Prioritize manufacturers that hold relevant international quality certifications and can provide detailed quality control documentation, as this reflects their formalized quality management capabilities.

Secondly, assess their production technology and equipment level. A reliable High Quality Flex FPCB Manufacturer should be equipped with advanced production and testing equipment, and be able to demonstrate their technological advantages in key processes such as signal integrity optimization and environmental resistance enhancement. Thirdly, evaluate their batch production consistency. Requesting sample testing and batch quality reports can help verify whether the manufacturer can maintain stable quality across different production batches.

Finally, consider their after-sales service and technical support. A professional High Quality Flex FPCB Manufacturer should provide timely technical consultation and after-sales support, helping clients solve quality-related issues that may arise during product assembly and use. This comprehensive service ensures a smooth cooperation process and protects the client’s product quality.

As high-end electronics continue to evolve toward intelligence and multi-functionality, High Quality Flex FPCB Manufacturer are actively advancing toward quality upgrading and application diversification. One key trend is the continuous improvement of quality standards to meet the more stringent requirements of emerging technologies, such as 5G, AI, and IoT. This includes optimizing signal integrity for high-frequency applications and enhancing durability for long-term use in complex environments.

Another trend is the expansion of high-quality product lines to cover more application scenarios. Manufacturers are developing high-quality flex FPCBs tailored to specific sectors, such as medical-grade flex FPCBs with biocompatibility and aerospace-grade products with extreme environmental resistance. Additionally, sustainability has become an important part of quality management, with more High Quality Flex FPCB Manufacturer adopting eco-friendly materials and production processes to achieve green and low-carbon manufacturing, aligning with global environmental protection trends.

In conclusion, a High Quality Flex FPCB Manufacturer is the core guarantee for the reliability and performance of high-end electronic products. Its rigorous quality management system, advanced production technology, and comprehensive quality control capabilities make it an indispensable partner for electronic brands. By selecting a reputable High Quality Flex FPCB Manufacturer that aligns with their quality requirements, businesses can enhance the competitiveness of their products and gain an edge in the global market. As the demand for high-quality, reliable electronic products continues to grow, the role of High Quality Flex FPCB Manufacturer will become even more prominent in shaping the future of the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB