-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 02. 2025, 11:36:27

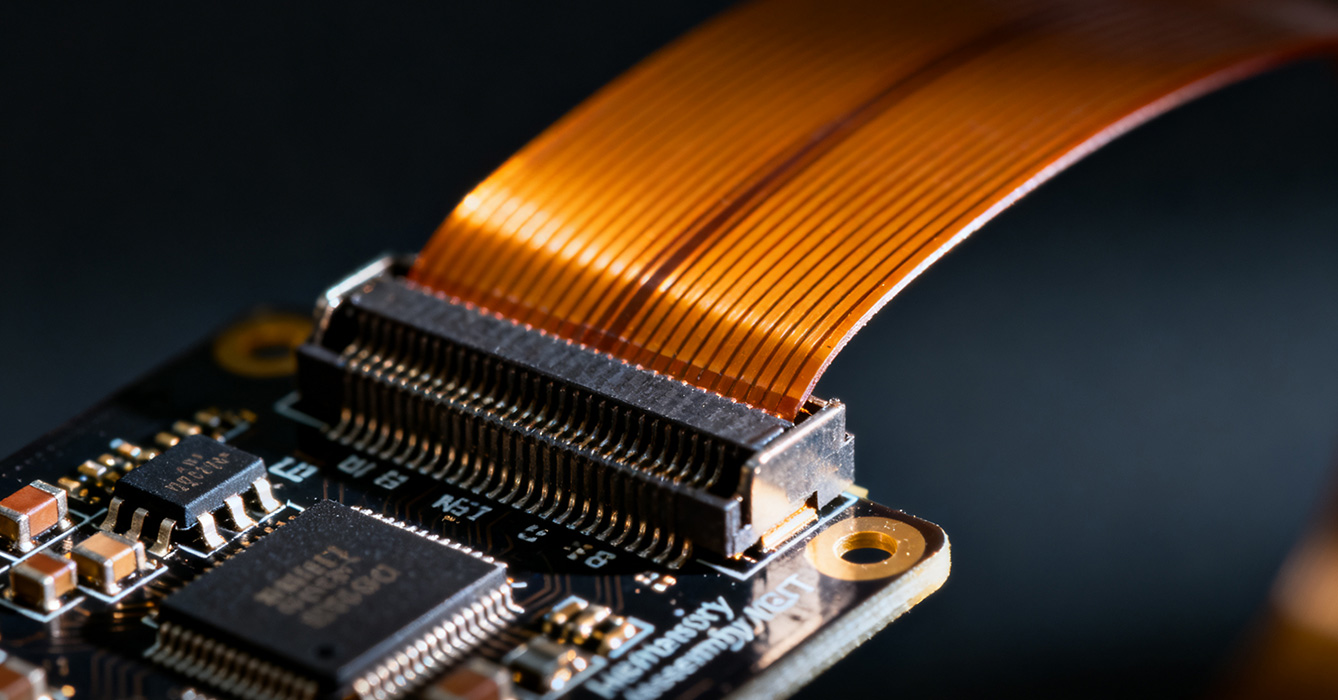

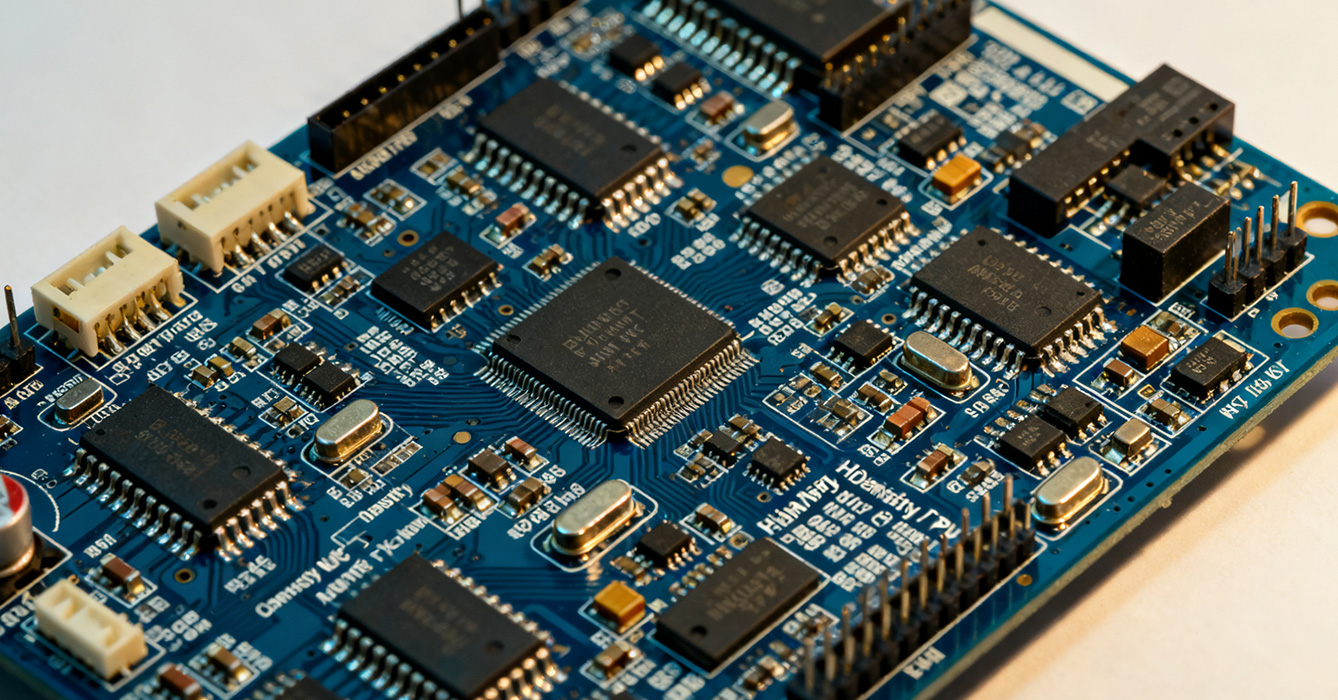

As electronic devices trend toward ultra-miniaturization, high functionality, and flexible form factors, High Density SMT FPC Assembly has emerged as a critical technology in advanced electronic manufacturing. This specialized assembly process combines the precision of high-density surface mount technology (SMT) with the flexibility of flexible printed circuits (FPCs), enabling the integration of hundreds of tiny components—such as microchips, resistors, and capacitors—onto flexible substrates. Unlike traditional rigid PCB SMT assembly, High Density SMT FPC Assembly requires unique expertise in handling flexible materials, controlling thermal stress, and ensuring precise component placement. For industries ranging from consumer electronics to medical devices and automotive systems, this assembly technology is a key enabler of products that balance compact design, high performance, and mechanical adaptability.

High Density SMT FPC Assembly delivers distinct benefits that address the core demands of modern electronic product design:

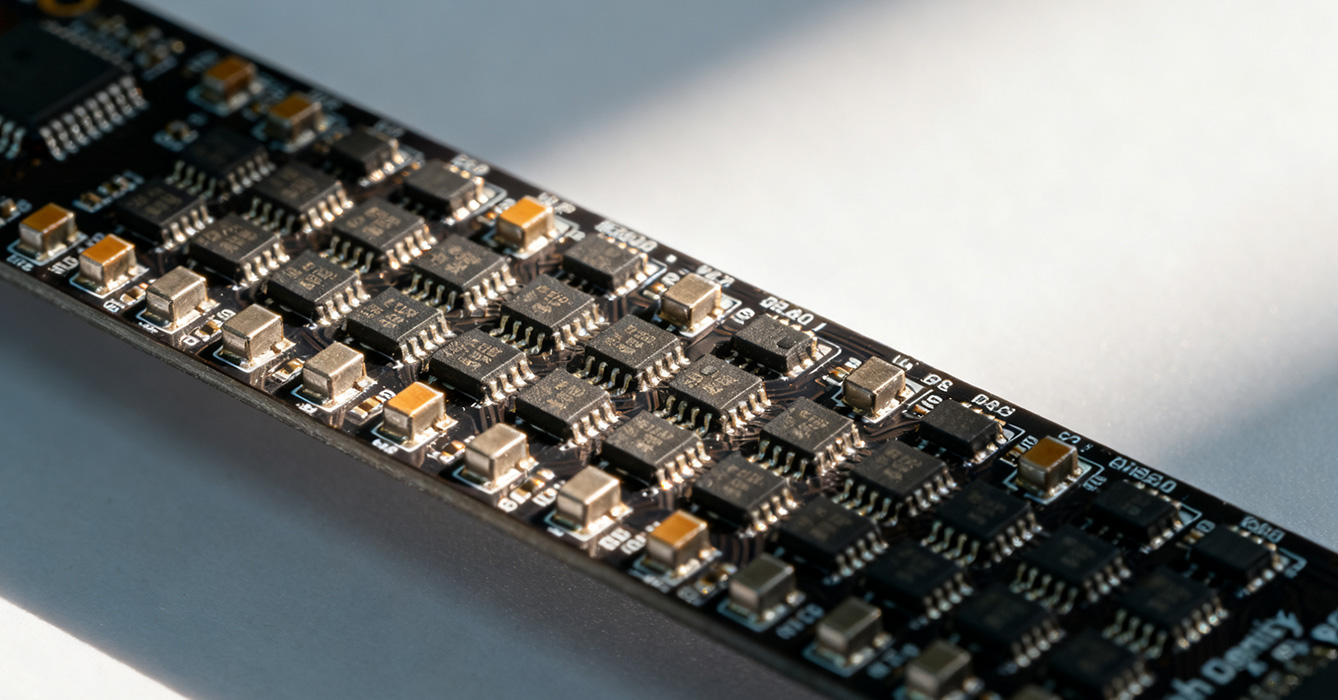

- Ultra-High Integration & Miniaturization: By leveraging high-density SMT贴装 (surface mount technology) capabilities, this assembly process enables the placement of ultra-small components (e.g., 01005 chips) at tight pitches on flexible FPC substrates. This significantly increases component density per unit area, allowing electronic devices to become smaller and lighter while incorporating more functions—critical for wearables, miniaturized medical sensors, and compact 5G modules.

- Mechanical Flexibility with Reliable Electrical Performance: Unlike rigid PCB assemblies that limit device form factor, High Density SMT FPC Assembly preserves the inherent flexibility of FPCs. The assembled circuits can bend, twist, or conform to curved surfaces without compromising the integrity of solder joints or component connections. This flexibility expands design possibilities for dynamic applications such as foldable smartphone hinges, robotic arms, and wearable health monitors.

- Enhanced Production Efficiency & Cost-Effectiveness: High Density SMT FPC Assembly leverages automated SMT equipment for precise, high-speed component placement, reducing manual intervention and human error. This automation improves production throughput and consistency, even for complex high-density layouts. Additionally, the integration of multiple functions onto a single FPC assembly reduces the number of interconnects and assembly steps, lowering overall manufacturing costs.

- Compatibility with High-Frequency & High-Power Applications: Advanced High Density SMT FPC Assembly processes use specialized materials (e.g., low-loss dielectrics) and precise soldering techniques to ensure stable signal transmission in high-frequency devices (e.g., 5G millimeter-wave modules). They also incorporate thermal management solutions to handle heat dissipation in high-power components, expanding the technology’s applicability to demanding electronic systems.

The combination of high-density SMT and flexible substrates presents unique challenges that require specialized technical solutions:

- Flexible Substrate Stability During Assembly: FPCs are prone to warping or stretching under the high temperatures and mechanical stress of SMT processing. Leading assembly providers use custom fixtures and vacuum holding systems to secure FPCs during component placement and reflow soldering, ensuring dimensional stability and precise component alignment.

- Precision Control for Tiny Component Placement: High-density assemblies require placing components with pitches as small as 0.3mm or less. Advanced SMT equipment with vision alignment systems and high-precision nozzles is used to achieve sub-micron placement accuracy, preventing short circuits or poor solder joints.

- Solder Joint Reliability on Flexible Substrates: Thermal cycling and mechanical bending can cause solder joint fatigue in FPC assemblies. Solutions include using lead-free solder alloys with enhanced ductility, optimizing reflow profiles to minimize thermal stress, and applying underfill materials for critical components to reinforce solder joints.

- Quality Inspection of High-Density Layouts: Traditional visual inspection is insufficient for high-density FPC assemblies with hidden solder joints. Assembly providers employ automated optical inspection (AOI) for surface defects and X-ray inspection to verify the integrity of solder joints under components (e.g., BGA, QFN), ensuring comprehensive quality control.

High Density SMT FPC Assembly is indispensable in sectors that demand compact, flexible, and high-performance electronic systems:

- Consumer Electronics: Powers foldable smartphones, wireless earbuds, smartwatches, and VR/AR headsets. The technology enables the integration of display drivers, sensors, wireless modules, and batteries into ultra-compact, flexible designs, enhancing user experience and product portability.

- Medical Devices: Enables miniaturized, wearable health monitors (e.g., ECG patches, glucose monitors) and minimally invasive surgical tools. High Density SMT FPC Assembly ensures reliable performance in biocompatible, flexible circuits that conform to human anatomy, while meeting strict medical quality standards.

- Automotive Electronics: Supports advanced driver assistance systems (ADAS), EV powertrain components, and in-vehicle infotainment systems. The assembly’s flexibility allows it to fit into tight automotive spaces, while its high reliability ensures stable operation under extreme temperatures, vibration, and electromagnetic interference (EMI).

- Industrial IoT & Robotics: Powers compact industrial sensors, robotic end-effectors, and IoT edge devices. High Density SMT FPC Assembly enables these devices to withstand harsh industrial environments (dust, humidity, temperature fluctuations) while maintaining high integration and flexibility for dynamic applications.

In conclusion, High Density SMT FPC Assembly is a transformative technology that bridges the gap between high-density component integration and flexible form factors. By addressing the unique challenges of assembling tiny components on flexible substrates, it enables the development of innovative electronic products that are smaller, more functional, and more adaptable than ever before. As the demand for compact, flexible electronics continues to grow across industries, the role of High Density SMT FPC Assembly in driving innovation and market competitiveness will only become more critical. For manufacturers seeking to develop cutting-edge products, partnering with a provider skilled in this specialized assembly process is essential to ensuring quality, reliability, and successful product commercialization.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB