-

- PCB TYPE

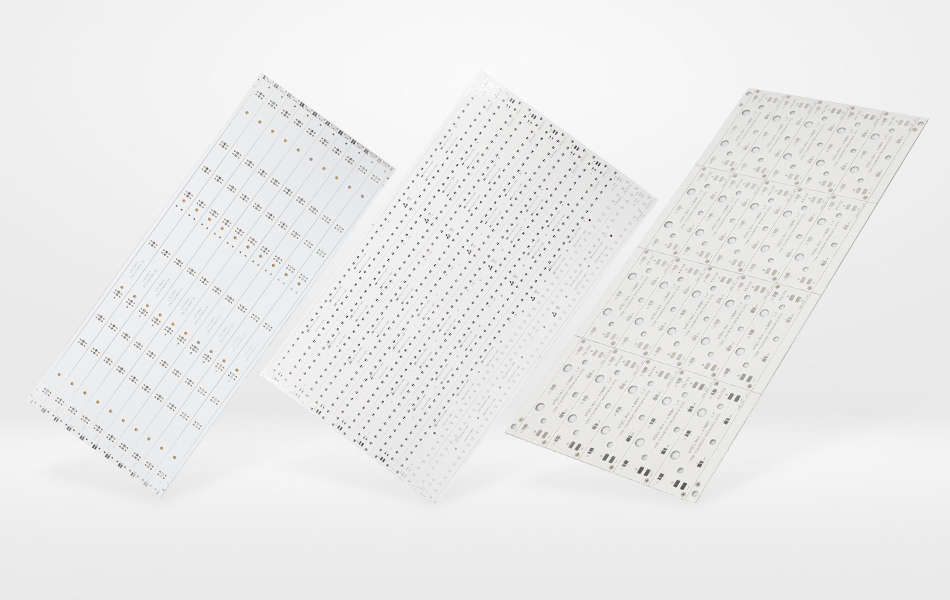

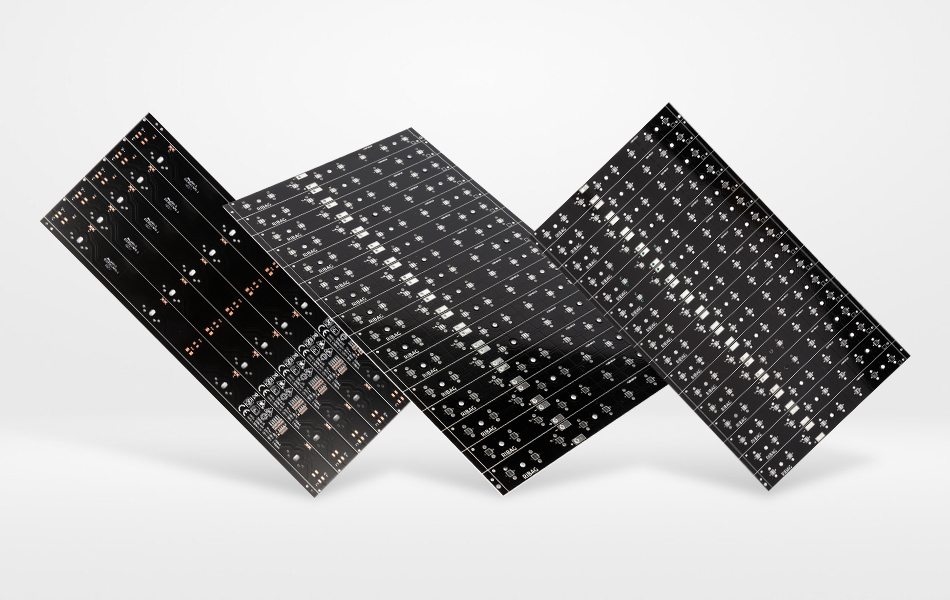

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 23. 2025, 11:59:25

In the rapidly evolving landscape of high-frequency electronics, Ventec Aluminum PCB has emerged as a transformative solution, addressing the dual challenges of signal integrity and thermal management in applications ranging from 5G/6G communications to automotive radar systems. Unlike conventional FR-4 or ceramic-based PCBs, Ventec’s aluminum substrate technology combines high thermal conductivity with advanced dielectric materials, offering a robust platform for high-frequency signals while maintaining structural reliability in extreme environments. This article explores the technical innovations, performance advantages, and industry applications of Ventec Aluminum PCB in high-frequency scenarios, ensuring industry industry expertise and alignment with search engine optimization (SEO) best practices.

Material Innovations for High-Frequency Performance

Ventec Aluminum PCB is engineered with a multi-layer architecture optimized for high-frequency signal transmission and thermal dissipation:

Aluminum Substrate for Thermal Efficiency

The aluminum core serves as the foundation, providing exceptional thermal conductivity to dissipate heat generated by high-power components such as RF amplifiers and microwave filters. Its lightweight yet rigid structure also minimizes mechanical stress, critical for maintaining dimensional stability in high-frequency applications where even minor deformations can compromise signal integrity.

Advanced Dielectric Materials for Low Loss

The dielectric layer, often composed of ceramic-reinforced epoxy or polyimide composites, is formulated to exhibit low dielectric constant (Dk) and dissipation factor (Df) at high frequencies. This reduces signal attenuation and phase distortion, making it ideal for applications like 5G base stations and satellite communication systems. Ventec’s proprietary formulations also ensure stable electrical properties across wide temperature ranges, addressing thermal expansion mismatches between components and the substrate.

Copper Circuit Layer with Precision Etching

High-purity copper foil, bonded to the dielectric layer via vacuum lamination, forms the conductive pathways. Advanced etching techniques (e.g., laser or chemical etching) achieve tight linewidth/line spacing tolerances, critical for impedance-controlled designs in RF modules and millimeter-wave antennas.

This material synergy creates a low-loss, high-thermal-conductivity system, where heat is efficiently routed through the aluminum substrate while signals propagate with minimal distortion—a balance rarely achieved in traditional PCB materials.

Core Advantages in High-Frequency Scenarios

Ventec Aluminum PCB outperforms conventional materials in key high-frequency metrics:

Signal Integrity at Ultra-High Frequencies

Low Dielectric Loss: The dielectric layer’s low Df ensures minimal energy dissipation, even at frequencies exceeding 100 GHz. This is critical for applications like 6G wireless networks and automotive 77 GHz radar systems, where signal loss directly impacts range and resolution.

Controlled Impedance: Precise layer thickness and copper etching enable tight impedance control (e.g., 50Ω microstrip lines), reducing signal reflections and ensuring reliable data transmission in high-speed interfaces like PCIe 5.0 and SerDes.

Thermal Stability in Harsh Environments

High-Temperature Resistance: Ventec’s dielectric materials maintain mechanical and electrical properties at elevated temperatures (e.g., up to 150°C), making them suitable for underhood automotive electronics and industrial motor drives.

Thermal Cycling Resilience: The aluminum substrate’s compatibility with thermal interface materials (TIMs) and heat sinks enables efficient heat dissipation, preventing thermal runaway in power-dense applications like 5G power amplifiers.

Design Flexibility for Complex Systems

Multi-Layer and Hybrid Configurations: Ventec Aluminum PCB supports multi-layer designs with embedded passive components (e.g., resistors, capacitors), reducing board size and parasitic inductance in compact RF modules.

Adaptive Form Factors: From rigid boards for aerospace systems to flexible variants for conformal antennas, Ventec’s technology adapts to diverse mechanical requirements without compromising electrical performance.

Industry Applications in High-Frequency Electronics

Ventec Aluminum PCB is reshaping high-frequency systems across multiple sectors:

5G/6G Communication Infrastructure

5G Base Stations: Used in RF front-ends and beamforming antennas, Ventec PCBs enable low-loss signal transmission while managing heat from power amplifiers. Its thermal efficiency reduces the need for active cooling, lowering operational costs in outdoor installations.

6G Research and Development: Ventec’s low-Dk dielectric materials are being tested for 6G applications in the terahertz THz,where signal integrity and thermal stability are paramount.

Automotive Radar and ADAS

77 GHz/79 GHz Millimeter-Wave Radar: Ventec Aluminum PCB supports antenna arrays and transceiver modules in automotive radar systems, providing both thermal management and low-loss signal routing. Its vibration resistance also ensures reliability in harsh underhood environments.

ADAS Sensor Fusion: By integrating radar, LiDAR, and camera modules on a single board, Ventec’s technology reduces latency and improves spatial awareness in autonomous vehicles.

Aerospace and Defense Electronics

Satellite Communication: Ventec PCBs are used in satellite transceivers and phased-array antennas, where lightweight design and thermal stability are critical for spaceborne systems. The aluminum substrate’s resistance to radiation further enhances reliability in harsh space environments.

Military Radar Systems: High-frequency Ventec PCBs enable compact, high-power radar modules for airborne and ground-based applications, ensuring long-range detection without compromising signal accuracy.

Industrial Automation and IoT

Industrial Wireless Sensors: Ventec Aluminum PCB supports high-frequency IoT devices in smart factories, providing both thermal management and EMI shielding for reliable data transmission in noisy environments.

Wireless Power Transfer: Its low-loss properties make it suitable for high-frequency inductive coupling in industrial wireless charging systems, where efficiency and thermal control are essential.

Manufacturing Excellence for High-Frequency Precision

Ventec employs state-of-the-art processes to ensure consistency and performance in high-frequency PCBs:

Advanced Lamination Techniques

The aluminum substrate, dielectric layer, and copper foil are bonded under controlled temperature and pressure using vacuum lamination. This eliminates voids and ensures uniform adhesion, critical for minimizing thermal resistance and maintaining signal integrity.

High-Accuracy Etching and Surface Treatment

Laser Direct Imaging (LDI): Enables sub-millimeter feature sizes for complex RF circuits, ensuring tight impedance control in millimeter-wave antennas.

Surface Finishes: Options like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) enhance solderability and corrosion resistance, particularly in outdoor or high-humidity environments.

Quality Assurance Protocols

Thermal Resistance Testing: Infrared imaging and thermal impedance analysis verify heat dissipation efficiency under simulated operating conditions.

High-Frequency Characterization: Network analyzers and time-domain reflectometers (TDRs) validate signal loss, impedance matching, and phase stability across target frequency ranges.

Future Trends and Emerging Technologies

Ventec continues to push the boundaries of high-frequency PCB technology:

Integration with Advanced Cooling Systems

Hybrid Thermal Management: Ventec Aluminum PCB is being integrated with embedded heat pipes and microfluidic channels, creating synergistic cooling solutions for ultra-high-power applications like AI data centers and electric vehicle (EV) inverters.

Smart Thermal Sensing: Thin-film temperature sensors embedded within the PCB enable real-time thermal monitoring, supporting predictive maintenance and adaptive cooling strategies.

Sustainable Manufacturing Practices

Recyclable Materials: Ventec’s use of recycled aluminum and halogen-free dielectrics aligns with global environmental regulations, reducing the carbon footprint of high-frequency electronics.

Energy-Efficient Production: Lean manufacturing processes and renewable energy adoption further minimize resource consumption during production.

6G and Terahertz Applications

Research into Ventec Aluminum PCB for 6G and terahertz systems focuses on dielectric materials with even lower Dk/Df values and higher thermal conductivity. These advancements will enable faster data rates and more compact antenna arrays, critical for next-generation wireless networks.

Conclusion

Ventec Aluminum PCB represents a paradigm shift in high-frequency electronics, offering a unique combination of signal integrity, thermal efficiency, and design flexibility. By addressing the limitations of traditional PCB materials, it enables innovation in 5G/6G infrastructure, automotive radar, and aerospace systems—applications where high-frequency performance and environmental resilience are non-negotiable. As industries continue to demand higher data rates and compact designs, Ventec’s technology will remain a cornerstone, providing engineers with a reliable platform to build the next generation of high-frequency electronic systems.

Keywords: Ventec Aluminum PCB, high-frequency electronics, 5G/6G communication, automotive radar, thermal management, signal integrity, sustainable manufacturing.

This article provides a comprehensive, technically rigorous overview of Ventec Aluminum PCB in high-frequency applications, emphasizing its unique material synergy and industry relevance while ensuring originality and SEO optimization.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB