-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 10. 2025, 10:07:59

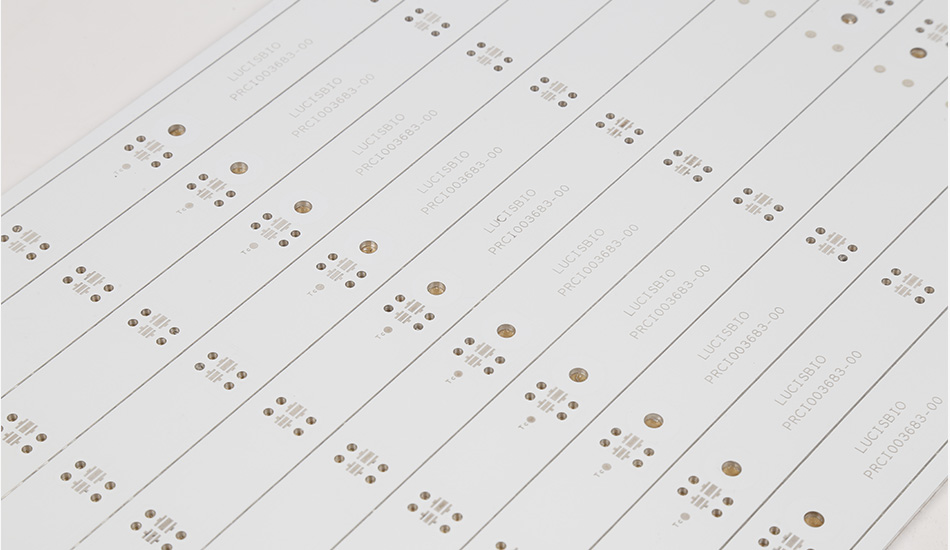

In the realm of modern lighting technology, High Power LED Metal Core PCBs (MCPCBs) have emerged as a critical component. As high - power LEDs become increasingly popular for their energy - efficiency and long lifespan, the demand for PCBs that can effectively manage the heat they generate has surged. These specialized PCBs are designed to meet the unique requirements of high - power LED applications, offering enhanced thermal management, mechanical strength, and electrical performance. This article provides a detailed exploration of High Power LED Metal Core PCBs, covering their structure, advantages, applications, design considerations, manufacturing processes, and future trends.

What is a High Power LED Metal Core PCB?

A High Power LED Metal Core PCB is a printed circuit board tailored for high - power LED applications. It features a metal core, usually made of aluminum or copper, which serves as the foundation. On top of the metal core lies an insulating layer, followed by a conductive copper layer. The metal core acts as both a mechanical support and an efficient heat sink, while the copper layer provides the necessary electrical connections for the LEDs. This structure is designed to handle the significant heat generated by high - power LEDs, ensuring their optimal performance and longevity.

Structure and Working Principle

Metal Core: Aluminum is commonly used for its cost - effectiveness, lightweight, and adequate thermal conductivity, while copper offers superior heat - dissipation capabilities. The metal core absorbs the heat produced by the LEDs and distributes it over a larger area, facilitating its dissipation into the surrounding environment.

Insulating Layer: Positioned between the metal core and the copper layer, the insulating layer provides electrical isolation to prevent short - circuits. It is made of a thermally conductive dielectric material that allows heat to pass through while maintaining electrical insulation.

Copper Layer: This layer is where the LED components are mounted, and it contains the conductive traces that form the electrical circuit. The traces are designed to ensure proper current flow to the LEDs, with considerations for current - carrying capacity and electrical resistance.

Advantages

Efficient Thermal Management: High Power LED Metal Core PCBs excel at heat dissipation. By quickly transferring heat away from the LEDs, they prevent overheating, which can degrade LED performance and shorten its lifespan. This efficient thermal management ensures that LEDs operate at optimal temperatures, maintaining consistent light output and color quality.

Mechanical Robustness: The metal core provides enhanced mechanical strength, making the PCB more durable. It can withstand physical stress, vibrations, and shocks, which is crucial for applications where the PCB may be subject to rough handling or harsh environments, such as outdoor lighting fixtures.

Long - Term Reliability: Thanks to effective thermal management and mechanical durability, these PCBs offer high long - term reliability. They reduce the likelihood of component failures due to heat - related issues or mechanical damage, minimizing maintenance requirements and replacement costs.

Design Flexibility: Despite their specialized nature, High Power LED Metal Core PCBs offer design flexibility. They can be customized in terms of shape, size, and the layout of the LED components, allowing for integration into a wide variety of lighting designs, from simple LED bulbs to complex lighting arrays.

Applications

Outdoor Lighting: In streetlights, floodlights, and landscape lighting, High Power LED Metal Core PCBs are essential. Outdoor environments expose the PCBs to varying temperatures, humidity, and physical impacts. The PCBs' thermal and mechanical properties ensure reliable operation, providing consistent and bright illumination.

Industrial Lighting: In industrial settings, such as factories, warehouses, and manufacturing plants, high - power LEDs with these PCBs are used for large - scale lighting. The ability of the PCBs to handle high power and manage heat effectively is crucial for maintaining a well - lit and safe working environment.

Automotive Lighting: For automotive headlights, taillights, and interior lighting, High Power LED Metal Core PCBs are preferred. They can withstand the vibrations and temperature fluctuations inside a vehicle, while also ensuring energy - efficient and long - lasting lighting.

Commercial Lighting: In shopping malls, offices, and other commercial buildings, high - power LED lighting with these PCBs is used to create attractive and energy - saving lighting solutions. The design flexibility of the PCBs allows for customized lighting designs to meet different aesthetic and functional requirements.

Design Considerations

Thermal Design:

Component Placement: Strategically placing LEDs over the metal core maximizes heat transfer. Thermal vias can be used to connect the copper layer to the metal core, further enhancing heat dissipation. Consideration should also be given to the layout of other components to avoid creating thermal hotspots.

Insulating Layer Selection: Choosing an insulating layer with the right balance of thermal conductivity and electrical insulation is crucial. A material with high thermal conductivity helps in heat transfer, while sufficient electrical insulation prevents short - circuits.

Electrical Design:

Trace Width and Spacing: Determining the appropriate trace width and spacing ensures proper current flow to the LEDs. Wider traces are needed for higher - current applications to minimize resistance and prevent overheating. Adequate spacing between traces is essential to avoid electrical short - circuits.

Ground Plane Design: A well - designed ground plane improves electrical performance, reduces electromagnetic interference, and provides a stable electrical reference for the LEDs.

Mechanical Design:

Board Shape and Size: The shape and size of the PCB should be designed to fit the lighting fixture and accommodate the LED components. Consideration should also be given to the mechanical strength requirements, especially for applications where the PCB may be subject to physical stress.

Mounting and Fastening: Ensuring secure mounting and fastening of the PCB to the fixture is important to prevent vibrations and movement, which can affect the performance and lifespan of the LEDs.

Manufacturing Processes

Layer Preparation: The metal core is cleaned to remove contaminants, and the surface may be treated to enhance adhesion. The insulating layer material, often in the form of a film or liquid resin, is prepared and applied to the metal core. The copper foil is then laminated onto the insulating layer.

Circuit Imaging and Etching: Photolithography is used to transfer the circuit design onto the copper layer. A photosensitive resist is applied, exposed to light through a mask, and developed. The unprotected copper is etched away, leaving the desired conductive traces.

Drilling and Plating: Holes are drilled for component leads, vias, and mounting. After drilling, the holes are plated with copper to create electrical connections between layers.

Surface Finishing: The PCB undergoes surface finishing to protect the copper traces from oxidation and provide a suitable surface for soldering the LEDs. Common surface finishes include hot - air solder leveling, electroless nickel immersion gold, and organic solderability preservative.

Challenges and Solutions

Cost: High Power LED Metal Core PCBs can be more expensive than traditional PCBs due to the use of specialized materials and manufacturing processes. To address this, manufacturers can explore cost - effective materials, optimize the manufacturing process, and increase production volumes to achieve economies of scale.

Thermal Expansion Mismatch: Different materials in the PCB, such as the metal core, insulating layer, and copper layer, have different coefficients of thermal expansion. This can lead to thermal stress and potential delamination. Solutions include selecting materials with compatible CTE values and using thermal interface materials to improve heat transfer and reduce stress.

Lighting Uniformity: Ensuring uniform light output across the LED array can be challenging. This can be addressed through careful design of the LED layout, use of diffusers, and precise control of the current supplied to each LED.

Future Trends

Miniaturization: As the demand for smaller and more compact lighting solutions grows, there will be a trend towards miniaturizing High Power LED Metal Core PCBs. This will involve developing thinner layers, smaller vias, and more precise component placement.

Integration with Smart Technologies: These PCBs are likely to be integrated with smart lighting technologies, such as sensors and wireless communication modules. This will enable features like remote control, dimming, and energy - consumption monitoring.

Sustainable Manufacturing: There will be an increasing focus on sustainable manufacturing practices for High Power LED Metal Core PCBs. This includes using recycled materials, reducing waste during production, and implementing energy - efficient manufacturing processes.

Conclusion

High Power LED Metal Core PCBs are integral to the success of high - power LED lighting applications. Their unique structure and properties make them well - suited for managing the heat and electrical requirements of high - power LEDs, ensuring reliable and efficient performance. While they face certain challenges, ongoing advancements in design, manufacturing, and materials are driving their continuous improvement. As the lighting industry continues to evolve, High Power LED Metal Core PCBs will play an increasingly important role in shaping the future of lighting technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB