-

- PCB TYPE

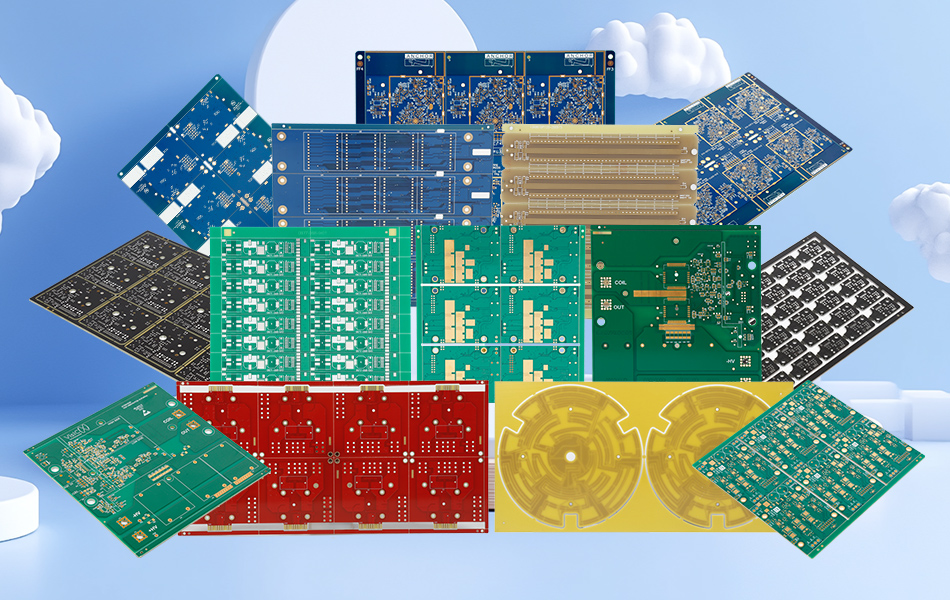

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 05. 2025, 09:05:06

In the demanding landscape of high-performance electronics, where temperature fluctuations can span from sub-zero to extreme heat, High Stability Low CTE FR4 has emerged as a material of choice for engineers seeking unparalleled dimensional stability. This advanced variant of glass-reinforced epoxy laminate combines the proven attributes of Low CTE FR4 with enhanced formulations that push the boundaries of thermal resilience, making it indispensable for applications where even minute dimensional changes can lead to catastrophic failures. Unlike standard Low CTE FR4, which focuses primarily on reducing thermal expansion, High Stability Low CTE FR4 is engineered to maintain consistent performance across extended temperature ranges, aggressive thermal cycling, and harsh environmental conditions. This article delves into the technical intricacies of High Stability Low CTE FR4, exploring its composition, performance metrics, manufacturing nuances, and critical applications in industries such as aerospace, automotive, and industrial automation.

High Stability Low CTE FR4 represents a leap forward in laminate technology, designed to address the most stringent stability requirements in electronics. While conventional Low CTE FR4 reduces thermal expansion to minimize stress, High Stability variants take this a step further by ensuring that this low expansion remains consistent over time, across wide temperature swings, and under prolonged exposure to heat. This "stability" is measured by the material’s ability to resist drift in CTE values, maintain mechanical strength after thousands of thermal cycles, and preserve electrical properties in extreme conditions—factors that separate it from standard Low CTE materials.

Key to this distinction is the material’s behavior above its glass transition temperature (Tg). While standard Low CTE FR4 may exhibit a noticeable increase in expansion once Tg is exceeded, High Stability Low CTE FR4 is formulated to delay this transition and minimize the post-Tg expansion spike. For example, where standard Low CTE FR4 might show a 300% increase in z-axis CTE above Tg, High Stability variants limit this to 200% or less, ensuring that even in transient over-temperature events, the material retains structural integrity. This makes it ideal for applications like satellite electronics, where brief but intense thermal spikes are common, or automotive underhood systems, where continuous operation near Tg is typical.

The superior performance of High Stability Low CTE FR4 stems from a meticulously optimized composition that synergizes resin chemistry, reinforcement, and additives to enhance long-term stability:

Advanced Resin Systems: Moving beyond standard novolac epoxies, High Stability Low CTE FR4 often uses multi-component resin blends, including cycloaliphatic epoxies and anhydride hardeners. These formulations form a highly cross-linked molecular structure with exceptional thermal endurance, resisting chain scission (breakdown) at elevated temperatures. The resin matrix is cured using a two-stage process—first at 180–200°C for 90 minutes, then post-cured at 200–220°C for an additional 60 minutes—to maximize cross-link density, a critical factor in preventing thermal degradation over time.

High-Performance Glass Reinforcement: Instead of standard E-glass, High Stability variants often incorporate S-glass or quartz fibers, which offer lower inherent CTE (3–4 ppm/°C for quartz vs. 5 ppm/°C for E-glass) and higher tensile strength. These fibers are woven into ultra-tight patterns (e.g., 106 weave, finer than 1080) to create a more uniform reinforcement network, reducing localized expansion hotspots. The fiber-to-resin ratio is increased to 65–70% by weight, leveraging the glass’s stability to counteract resin expansion.

Nano-Engineered Fillers: Beyond conventional silica fillers, High Stability Low CTE FR4 uses nano-scale fillers (50–100 nm) such as fumed silica or alumina nanoparticles. These tiny particles disperse more uniformly in the resin, creating a "nanocomposite" that inhibits molecular movement in the epoxy matrix—key to reducing CTE drift over time. Filler loading is carefully balanced at 30–40% by weight; higher concentrations would improve CTE but compromise processability, while lower levels would reduce stability.

Stabilizing Additives: Anti-oxidants are incorporated to prevent resin degradation under prolonged heat exposure, while thermal stabilizers (e.g., hindered phenols) slow down the breakdown of chemical bonds at temperatures near Td. These additives ensure that the material’s properties remain consistent even after 10,000+ hours of operation at 150°C, a requirement for aerospace and military applications.

The physical properties of High Stability Low CTE FR4 are defined by their consistency across time and temperature, with datasheets emphasizing metrics that reflect long-term stability:

Thermal Expansion Consistency: In-plane CTE is 6–10 ppm/°C (below Tg) and 25–35 ppm/°C (above Tg), with minimal variation (<1 ppm/°C) across production batches. Z-axis CTE is 35–50 ppm/°C (below Tg) and 120–180 ppm/°C (above Tg), with the critical distinction that these values remain stable even after 1,000 thermal cycles. This contrasts with standard Low CTE FR4, where CTE can drift by 2–3 ppm/°C after cycling.

Dimensional Stability Over Time: After 5,000 hours of exposure to 150°C, High Stability Low CTE FR4 shows total dimensional change of ≤0.05%, compared to 0.1–0.15% for standard Low CTE materials. This long-term stability is vital for precision applications like optical communication modules, where component alignment must be maintained over years of operation.

Moisture Resistance: Despite its high filler content, High Stability Low CTE FR4 achieves moisture absorption ≤0.15% (24-hour immersion), comparable to standard FR4. This is achieved through hydrophobic surface treatments on fillers and resin modifiers that reduce water uptake—critical for marine or outdoor electronics where humidity is constant.

Surface Hardness: A higher Rockwell hardness (M scale: 100–110) than standard Low CTE FR4, due to dense filler packing, ensures resistance to scratch and indentation during handling and assembly, preserving surface integrity for reliable soldering.

High Stability Low CTE FR4’s electrical properties are engineered to remain consistent under thermal stress, making it suitable for high-frequency and high-voltage applications where signal integrity is critical:

Dielectric Constant (Dk) Stability: Dk ranges from 4.4–4.8 at 1 MHz, with a maximum variation of ≤2% across -55°C to +175°C. This is significantly better than standard Low CTE FR4, which may show 4–5% variation in the same range. For 5G and radar systems operating at 28 GHz, this stability ensures minimal impedance drift, reducing signal reflection and loss.

Dissipation Factor (Df): ≤0.02 at 1 MHz, with a negligible increase (≤0.022 at 150°C) due to the high-quality resin and filler interface. This low and stable Df makes High Stability Low CTE FR4 ideal for long-haul communication PCBs, where signal attenuation over distance must be minimized.

High-Temperature Insulation Resistance: Volume resistivity remains ≥10¹³ Ω·cm at 150°C (after 1,000 hours), a 10x improvement over standard Low CTE FR4. This ensures reliable insulation in high-temperature power electronics, such as EV inverters, where leakage current can cause efficiency losses or safety hazards.

Arc Resistance: ≥120 seconds (per ASTM D495), exceeding standard FR4’s 90 seconds, due to the flame-retardant fillers and high cross-link density. This makes it suitable for high-voltage applications like industrial transformers or grid-tied inverters.

The mechanical properties of High Stability Low CTE FR4 are optimized to withstand the cumulative stress of repeated thermal expansion and contraction:

Tensile Strength Retention: ≥400 MPa after 1,000 thermal cycles (-55°C to +150°C), representing a retention rate of 90% (vs. 70–75% for standard Low CTE FR4). This high retention ensures the material resists cracking in vibration-prone environments like aerospace launch vehicles.

Flexural Modulus Stability: Maintains 85% of its room-temperature flexural modulus (25 GPa) at 150°C, compared to 65–70% for standard variants. This rigidity is critical for maintaining component alignment in precision assemblies, such as laser diode mounts or sensor arrays.

Peel Strength After Aging: ≥1.0 N/mm for 1 oz copper after 500 hours at 150°C, ensuring copper traces remain bonded even in prolonged high-heat conditions. This is achieved through specialized coupling agents that resist thermal oxidation at the copper-resin interface.

Impact Resistance Under Cold Conditions: Charpy impact strength ≥15 kJ/m² at -55°C, a key improvement over standard Low CTE FR4 (12–13 kJ/m²), making it suitable for cryogenic applications like LNG sensors or space-based electronics.

Thermal performance defines High Stability Low CTE FR4, with properties tailored to excel in the most extreme conditions:

Elevated Glass Transition Temperature (Tg): 170–190°C, 20–30°C higher than standard Low CTE FR4, achieved through the advanced resin system. This higher Tg extends the range of temperatures where the material remains in its rigid, low-expansion state, critical for applications like turbine engine sensors operating at 150–160°C.

High Decomposition Temperature (Td): ≥350°C, ensuring compatibility with aggressive soldering processes (e.g., laser soldering with peak temperatures up to 300°C) and resistance to thermal degradation in long-term high-heat operation.

Thermal Conductivity: 0.4–0.5 W/m·K, enhanced by boron nitride fillers that form thermally conductive pathways in the resin matrix. This improves heat spreading from high-power components like GaN transistors, reducing hotspots that can accelerate aging.

Thermal Cycling Endurance: Survives 3,000+ thermal cycles (-55°C to +150°C) with no delamination, via cracking, or significant CTE drift. This is validated through rigorous testing per MIL-STD-883 Method 1010, making it qualified for military and aerospace applications.

The advanced composition of High Stability Low CTE FR4 demands precise manufacturing controls to realize its performance potential:

Lamination: Ultra-high pressure (400–500 psi) and extended cure cycles (180–240 minutes) are required to ensure complete resin infiltration of the dense fiber weave and uniform dispersion of nano-fillers. A controlled cooling rate (1°C/min) prevents internal stresses that could compromise dimensional stability.

Drilling and Routing: The combination of hard fillers and tight fiber weave requires diamond-coated carbide tools with specialized geometries (e.g., parabolic flutes) to minimize tool wear and resin smearing. Drill speeds are reduced to 10,000–40,000 RPM, with feed rates of 0.05–0.15 mm/rev, to ensure clean via walls.

Plating and Surface Treatment: Plasma desmearing is preferred over chemical methods, as it more effectively removes resin from around nano-fillers without damaging the fiber-resin interface. This ensures uniform copper adhesion in vias, critical for high-reliability connections.

Solder Mask and Coating: UV-curable solder masks with high thermal resistance (Tg ≥200°C) are required to match the laminate’s stability. A thin layer of silicone conformal coating is often applied post-assembly to further protect against moisture and thermal stress.

High Stability Low CTE FR4 meets the most stringent industry standards, reflecting its suitability for safety-critical applications:

IPC-4101/42: Classified under Type 3 (ultra-high performance) with CTE requirements tighter than standard Low CTE FR4 (in-plane ≤10 ppm/°C, z-axis ≤50 ppm/°C below Tg).

MIL-PRF-31032: Qualified for military applications, with additional testing for radiation resistance (total ionizing dose ≥100 kRad) and thermal vacuum performance, ensuring reliability in space environments.

AEC-Q200 Grade 0: Complies with the highest automotive standard, which requires operation from -40°C to +150°C for 1,000 hours, making it suitable for EV battery management systems and powertrain controllers.

UL 94 V-0 (1.6 mm): Maintains flame retardancy even after thermal aging, critical for aerospace and industrial applications where fire safety is paramount.

High Stability Low CTE FR4 undergoes rigorous testing beyond standard protocols to validate its stability claims:

Long-Term Thermal Aging: Exposed to 175°C for 10,000 hours, with periodic testing of CTE, mechanical strength, and electrical properties. Acceptance criteria require <5% change in key metrics, ensuring long-term reliability.

Thermal Shock Testing: 1,000 cycles of -196°C (liquid nitrogen) to +150°C (hot oil) to simulate extreme temperature swings, with no visible cracks or delamination—critical for space and cryogenic applications.

Vibration-Thermal Combined Testing: Subjected to random vibration (20–2,000 Hz, 20 g RMS) while undergoing thermal cycling (-55°C to +150°C), replicating the harsh environment of aerospace launch vehicles. High Stability Low CTE FR4 shows <1% via failure rate, compared to 5–10% for standard Low CTE materials.

Nano-CT Scanning: 3D imaging of the laminate structure before and after testing confirms uniform filler dispersion and no void growth, validating the material’s structural integrity at the microscale.

High Stability Low CTE FR4 is specified in applications where failure is not an option:

Aerospace and Space Systems: Satellite communication payloads, launch vehicle avionics, and planetary rover electronics rely on its ability to withstand extreme temperature swings (-150°C to +120°C) and radiation exposure. Its stability ensures antenna alignment and sensor calibration remain precise over multi-year missions.

Automotive Ultra-High-Voltage (UHV) Systems: EVs with 800V+ architectures use High Stability Low CTE FR4 in power electronics (inverters, converters) to handle the thermal stress of high-current operation, preventing via failures that could cause battery fires.

Industrial Turbine Sensors: Gas and steam turbine control systems, operating at 150–180°C, depend on the material’s stability to maintain the accuracy of vibration and temperature sensors, which are critical for preventing catastrophic turbine failures.

Medical Imaging Equipment: MRI and CT scanner PCBs use High Stability Low CTE FR4 to maintain component alignment, ensuring image resolution remains consistent even during prolonged operation that generates heat.

While unmatched in its class, High Stability Low CTE FR4 has limitations that guide material selection:

Cost: 50–70% more expensive than standard Low CTE FR4, due to specialized raw materials (nano-fillers, S-glass) and extended manufacturing processes. This restricts its use to high-value, safety-critical applications.

Weight: Slightly higher density (2.0–2.2 g/cm³) than standard FR4, a consideration for weight-sensitive aerospace applications where every gram impacts fuel efficiency.

Emerging alternatives include ceramic matrix composites (CMCs) with near-zero CTE but at 3–4x the cost, and carbon fiber-reinforced polymers (CFRPs) with excellent stability but poor electrical insulation. For most applications, however, High Stability Low CTE FR4 remains the optimal balance of performance, cost, and processability.

Research and development continue to push the material’s capabilities:

Graphene-Enhanced Formulations: Adding graphene nanoplatelets to the resin matrix aims to reduce in-plane CTE to ≤5 ppm/°C while improving thermal conductivity to 0.8–1.0 W/m·K, targeting next-gen 6G and quantum computing applications.

Self-Healing Resins: Incorporating microcapsules of healing agents that rupture under thermal stress, repairing microcracks in the resin matrix to extend service life in extreme environments.

Recyclable Variants: Developing bio-based epoxy resins with high cross-link density, combined with recycled glass fibers, to reduce environmental impact without sacrificing stability—aligning with global sustainability goals.

High Stability Low CTE FR4 represents the pinnacle of laminate technology for applications demanding uncompromising dimensional stability and thermal resilience. By combining advanced resin chemistry, high-performance reinforcement, and nano-engineered fillers, it delivers consistent performance across extreme temperatures, aggressive thermal cycling, and prolonged heat exposure—factors that make it indispensable in aerospace, automotive, and industrial sectors. As electronics continue to operate in increasingly harsh environments, High Stability Low CTE FR4 will play a critical role in enabling next-generation technologies, from deep-space probes to ultra-high-

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB