-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 23. 2025, 09:09:57

In the dynamic landscape of electronics, the pursuit of miniaturization and enhanced functionality has led to a surge in heat generation within electronic devices. Traditional PCBs often struggle to manage this heat effectively, resulting in performance degradation, component failures, and shortened device lifespans. Aluminum PCBs with high thermal conductivity have emerged as a game - changing solution, leveraging the unique properties of aluminum to address these thermal challenges. This article explores the various aspects of high thermal conductivity aluminum PCBs, including their structure, benefits, design considerations, manufacturing processes, applications, and market trends.

Structure of High Thermal Conductivity Aluminum PCBs

Layer Composition

A high thermal conductivity aluminum PCB typically features a multi - layer structure. At its core lies the aluminum substrate, which serves as the primary heat - dissipation medium. The aluminum substrate not only offers excellent thermal conductivity but also provides mechanical stability to the PCB, enabling it to withstand physical stress in various applications.

Sandwiched between the aluminum substrate and the outer copper layers is the dielectric layer. This layer plays a dual role: it provides electrical insulation to prevent short - circuits between the conductive copper traces and the aluminum substrate, while also facilitating heat transfer. Specialized dielectric materials, often enhanced with thermally conductive fillers, are used to optimize the balance between electrical and thermal performance.

The outer copper layers are patterned to form the electrical traces, pads, and planes required for component interconnection and signal transmission. Copper's high electrical conductivity makes it ideal for this purpose, and it also contributes to the initial stage of heat transfer from components to the aluminum substrate.

Material Selection

The choice of materials for each layer is crucial. For the aluminum substrate, alloys are selected based on a balance of thermal conductivity, mechanical strength, and cost - effectiveness. Different alloys offer varying properties, such as enhanced corrosion resistance or higher strength, to suit specific application requirements.

The dielectric material is carefully formulated, with thermally conductive polymers often filled with ceramic particles like aluminum oxide or boron nitride. These fillers improve the dielectric layer's thermal conductivity without sacrificing its electrical insulation capabilities. The thickness of the dielectric layer is optimized to ensure efficient heat transfer while maintaining reliable electrical isolation.

High - purity copper foils are used for the copper layers. The purity of the copper directly impacts its electrical conductivity, and the thickness is determined according to the current - carrying capacity and heat - dissipation needs of the PCB.

Advantages of High Thermal Conductivity Aluminum PCBs

Exceptional Heat Dissipation

The most significant advantage of these PCBs is their ability to efficiently dissipate heat. In applications with high - power components, such as power transistors, LEDs, and advanced integrated circuits, substantial heat is generated during operation. High thermal conductivity aluminum PCBs quickly transfer this heat away from components. The aluminum substrate acts as a large heat sink, absorbing heat from the copper layers and distributing it across its surface for effective dissipation into the environment. This helps maintain components within their optimal operating temperature range, enhancing device performance and reliability.

Robust Durability

The aluminum substrate provides high thermal conductivity aluminum PCBs with enhanced mechanical strength. Aluminum's rigidity makes the PCB resistant to bending, vibration, and shock, which is particularly valuable in harsh environments. For example, in automotive electronics, where PCBs are exposed to continuous vibrations and temperature fluctuations, these PCBs can withstand such conditions without deforming or damaging components, reducing maintenance and replacement needs.

Extended Component Lifespan

By effectively managing heat, high thermal conductivity aluminum PCBs contribute to extending the lifespan of electronic components. High temperatures accelerate component degradation and lead to premature failure. When components are mounted on these PCBs, the lower operating temperatures achieved through efficient heat dissipation slow down the aging process, reducing the cost of component replacement and improving overall system reliability.

Environmental Friendliness

Aluminum is a highly recyclable material, making high thermal conductivity aluminum PCBs an environmentally friendly choice. At the end of a product's life cycle, the aluminum substrate can be easily separated and recycled, minimizing electronic waste. Additionally, their efficient heat - dissipation capabilities can reduce the need for additional cooling components, leading to energy savings and more sustainable device operation.

Design Considerations for High Thermal Conductivity Aluminum PCBs

Thermal Design

Component Placement

Strategic component placement is vital for effective thermal management. Heat - generating components should be positioned to maximize heat transfer to the aluminum substrate. This may involve placing them directly over the substrate or near thermal vias, which are small conductive holes connecting different layers to the aluminum substrate. Grouping components by heat - generation levels and placing high - heat components in areas with better heat - dissipation paths further optimize thermal performance.

Thermal Via Design

Thermal vias play a key role in heat transfer within the PCB. Their size, number, and distribution need to be optimized based on component heat - generation characteristics. Designers use specialized software to simulate heat flow and determine the best thermal via configuration, ensuring efficient heat conduction from components to the aluminum substrate.

Heat - Sink Integration

In some applications, integrating heat sinks is necessary to enhance heat dissipation. Good thermal contact between the heat sink and the aluminum substrate, achieved through thermal interface materials, is essential. The design of the heat sink, including its size, shape, and fin configuration, should be tailored to the PCB's heat - dissipation requirements.

Electrical Design

Trace Routing

Trace routing in high thermal conductivity aluminum PCBs requires careful planning. Designers must consider signal integrity, impedance matching, and crosstalk, while also accounting for the impact of the aluminum substrate on electromagnetic fields. Specialized design software helps optimize trace widths, lengths, and spacings to ensure reliable signal transmission.

Power and Ground Plane Design

Power and ground plane design is crucial for power distribution and reducing electromagnetic interference (EMI). Well - designed planes ensure a stable electrical supply to components. Integrating power and ground plane design with thermal design, such as using thermal vias to connect planes to the aluminum substrate, helps manage heat generated by electrical current.

Design for Manufacturability

Adhering to design for manufacturability principles simplifies production. Using standard component footprints, avoiding complex shapes, and ensuring compatibility with manufacturing processes reduce production costs and shorten time - to - market. Clear design guidelines for fabricators, including soldering process specifications and feature tolerances, are also important.

Manufacturing Processes of High Thermal Conductivity Aluminum PCBs

Material Preparation

The manufacturing process begins with material preparation. High - quality aluminum sheets are selected and cut to the required size and shape for the substrate. The dielectric material is prepared by mixing base resin with thermally conductive fillers and then processed into sheets or pre - impregnated onto a carrier. High - purity copper foils are also prepared to the desired thickness.

Lamination

Lamination bonds the aluminum substrate, dielectric layer, and copper foils together. Heat and pressure are applied to cure the dielectric material, creating a strong bond. Precise control of lamination parameters, such as temperature, pressure, and time, is necessary to avoid defects like voids or delaminations that could affect PCB performance.

Drilling and Plating

After lamination, drilling creates holes for vias, component mounting, and electrical connections. High - precision drilling machines ensure accurate hole placement and clean walls. The drilled holes are then electroplated with copper to create electrical connections and provide a solderable surface for component attachment.

Circuit Patterning

Photolithography is commonly used for circuit patterning. A photosensitive resist is applied to the copper surface, exposed to ultraviolet light through a patterned mask, and then developed. The remaining copper is etched away to form the electrical circuits, with careful control to ensure accurate trace widths and no shorts or open circuits.

Applications of High Thermal Conductivity Aluminum PCBs

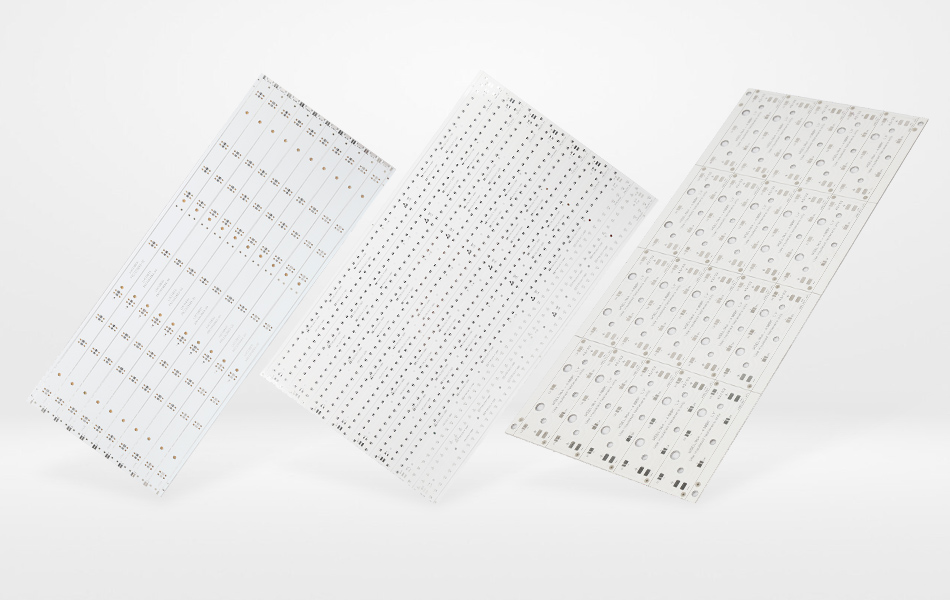

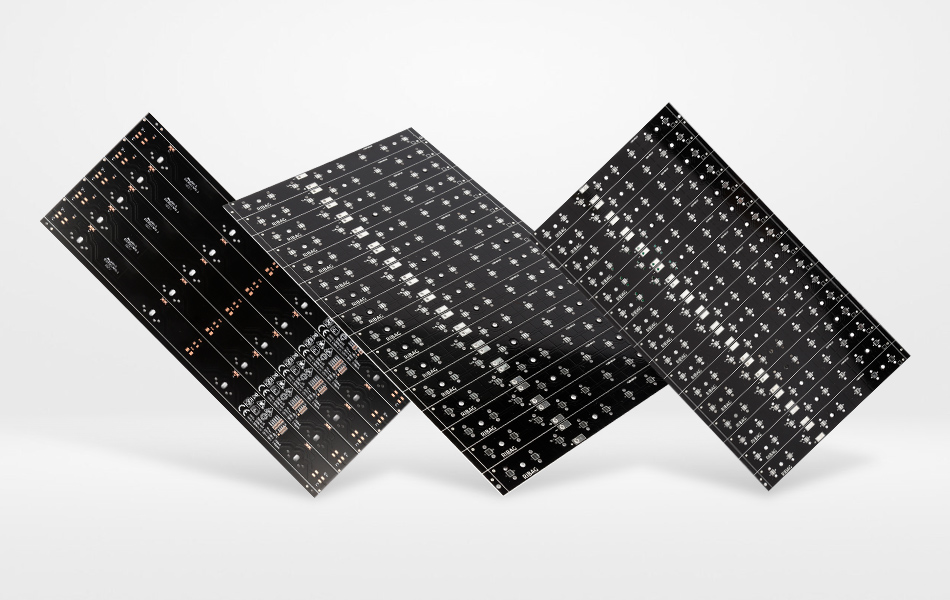

LED Lighting

High thermal conductivity aluminum PCBs are widely used in LED lighting. LEDs generate significant heat during operation, and these PCBs efficiently dissipate this heat, maintaining LED brightness and extending their lifespan. Their mechanical strength also makes them suitable for various lighting fixtures, including those in outdoor and industrial settings.

Power Electronics

In power electronics applications like power supplies, inverters, and motor drives, high - power components generate substantial heat. These PCBs effectively manage the heat, improving device efficiency and component lifespan, and ensuring reliable operation of power electronics systems.

Automotive Electronics

The automotive industry increasingly adopts high thermal conductivity aluminum PCBs for systems such as engine control units, advanced driver - assistance systems, and infotainment systems. These PCBs can withstand the harsh vehicle environment, with its vibrations, temperature fluctuations, and mechanical stress, while efficiently managing heat to ensure reliable electronic system operation.

Telecommunications

In telecommunications equipment, including base stations and routers, these PCBs are used to handle the heat generated by high - power components. They ensure stable signal processing and transmission by maintaining component temperatures within acceptable ranges, even in high - heat - generating environments.

Consumer Electronics

Consumer devices such as smartphones, tablets, and laptops also benefit from high thermal conductivity aluminum PCBs. As these devices become more powerful, the need for effective heat management grows. These PCBs help prevent performance throttling due to overheating, enhancing the user experience and extending device lifespan.

Market Dynamics of High Thermal Conductivity Aluminum PCBs

Market Growth

The market for high thermal conductivity aluminum PCBs is experiencing significant growth, driven by increasing demand in various industries. The expansion of LED lighting, the growth of the automotive and telecommunications sectors, and the continuous advancement of consumer electronics are all fueling market growth. As more industries recognize the benefits of these PCBs, the demand is expected to continue rising.

Competitive Landscape

The market is highly competitive, with both established and emerging manufacturers vying for market share. Key competitive factors include product quality, cost - effectiveness, technological innovation, and customer service. Manufacturers are constantly investing in research and development to improve PCB performance and reduce production costs.

Challenges

Challenges in the market include high production costs due to the use of specialized materials and manufacturing processes. The complexity of designing and manufacturing high thermal conductivity aluminum PCBs also increases as electronics become more advanced. Ensuring consistent quality in mass production is another significant challenge for manufacturers.

Future Trends

Future trends in high thermal conductivity aluminum PCBs include advancements in materials to further improve thermal and electrical performance. Integration with emerging technologies such as 5G, the Internet of Things (IoT), and artificial intelligence (AI) will also drive innovation. Additionally, there will be a greater focus on sustainable manufacturing processes to meet environmental requirements.

Conclusion

High thermal conductivity aluminum PCBs have become indispensable in modern electronics, offering superior heat management, durability, and other benefits across a wide range of applications. Despite the challenges faced in the market, ongoing advancements and emerging trends present significant opportunities for growth and innovation. As the electronics industry continues to evolve, these PCBs will play an increasingly crucial role in enabling the development of more efficient, reliable, and high - performing electronic devices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB