-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 22. 2025, 15:32:10

In the automotive industry, where safety, performance, and durability are non-negotiable, IATF 16949 certified auto PCBs (Printed Circuit Boards) have become indispensable. As vehicles evolve into complex electronic ecosystems—integrating advanced driver-assistance systems (ADAS), electric powertrains, and connected features—the demand for PCBs that meet rigorous quality standards has surged. IATF 16949, the global quality management standard for automotive production, sets the benchmark for PCB manufacturing, ensuring consistency, traceability, and reliability across the supply chain. This article explores the significance of IATF 16949 certification for auto PCBs, their technical requirements, application in critical automotive systems, and the role they play in driving innovation in automotive electronics.

Understanding IATF 16949 Certification for Auto PCBs

IATF 16949 is a specialized quality management standard derived from ISO 9001, tailored to the unique demands of the automotive industry. For auto PCBs, certification signifies adherence to processes that minimize defects, enhance traceability, and ensure compliance with automotive OEM (Original Equipment Manufacturer) requirements.

Core Principles of IATF 16949 for PCBs

Risk-Based Thinking: Manufacturers identify potential failures in PCB design, materials, and production, implementing preventive measures to mitigate risks—critical for PCBs used in safety-critical systems like braking or steering electronics.

Process Approach: Standardized workflows for PCB fabrication, from material selection to final inspection, ensure consistency across production batches. This reduces variability, a key challenge in automotive electronics where even minor defects can compromise safety.

Continuous Improvement: Data-driven feedback loops (e.g., defect analysis, customer complaints) drive ongoing enhancements in PCB manufacturing processes, aligning with automotive’s relentless pursuit of quality.

Supplier Management: IATF 16949 mandates strict oversight of PCB raw material suppliers (e.g., copper, dielectrics, solder masks), ensuring upstream quality in the supply chain.

Why Certification Matters for Auto PCBs

Automotive PCBs operate in harsh environments—exposed to vibration, temperature extremes, moisture, and chemical exposure. IATF 16949 certification ensures these PCBs are engineered to withstand such conditions through:

Rigorous Testing: Certified PCBs undergo environmental stress tests (thermal cycling, vibration, humidity) to validate durability.

Traceability: Full documentation of materials, production steps, and inspections allows OEMs to trace PCBs back to their origin, critical for recalls or root-cause analysis.

Compliance with OEM Specifications: Certification aligns PCB manufacturing with strict standards set by automakers (e.g., Ford, Toyota, Tesla), ensuring compatibility and performance in their systems.

Technical Requirements for IATF 16949 Certified Auto PCBs

IATF 16949 certified auto PCBs must meet specialized technical criteria to support automotive electronics’ unique demands:

Material Selection and Compatibility

High-Temperature Resistance: PCBs use substrates and dielectrics that withstand extreme temperatures (from sub-zero cold to engine-compartment heat), preventing delamination or insulation breakdown.

Chemical and Moisture Resistance: Materials resist degradation from oils, coolants, and humidity, ensuring reliability in underhood or cabin environments.

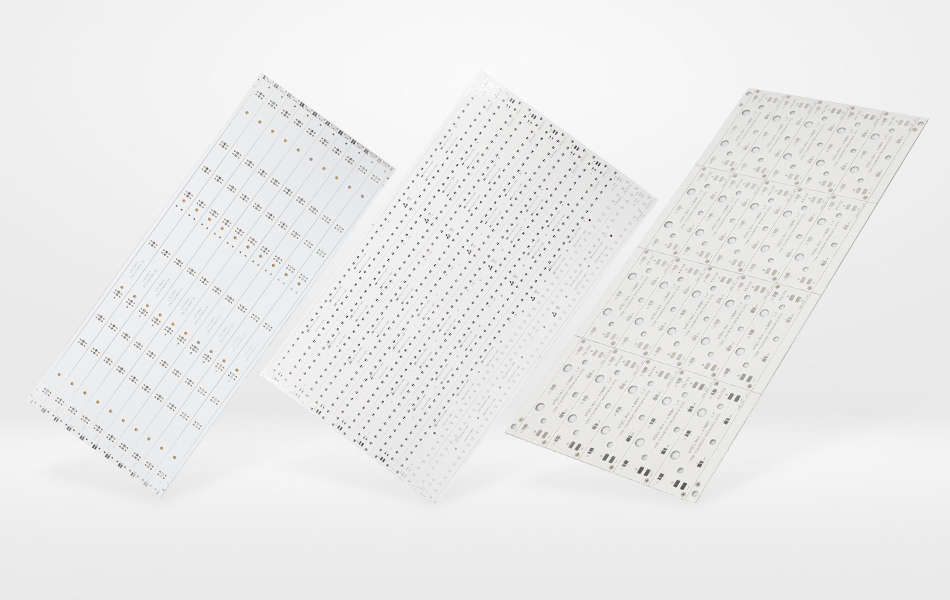

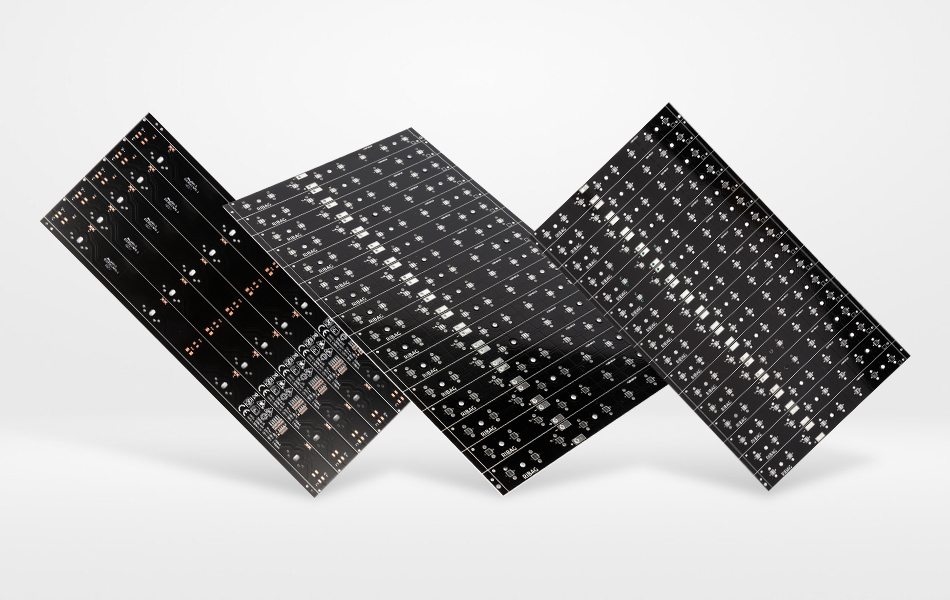

Thermal Conductivity: For power-dense applications (e.g., EV inverters, battery management systems), PCBs integrate thermally conductive substrates (e.g., aluminum-based laminates) to dissipate heat, reducing component stress.

Design for Automotive Environments

Vibration and Shock Tolerance: PCB layouts minimize stress points, with reinforced solder joints and rigid substrates to withstand vehicle vibration—critical for ADAS sensors and infotainment systems.

Signal Integrity: High-frequency PCBs (used in radar, LiDAR, and 5G connectivity) are designed to reduce electromagnetic interference (EMI), ensuring accurate data transmission in noisy automotive environments.

Miniaturization and Integration: As vehicles pack more electronics into limited space, certified PCBs support high-density interconnect (HDI) designs, enabling compact, multi-functional systems without sacrificing reliability.

Manufacturing Precision

Controlled Lamination: Advanced bonding techniques ensure uniform adhesion between layers, preventing delamination during thermal cycling—a common failure mode in uncertified PCBs.

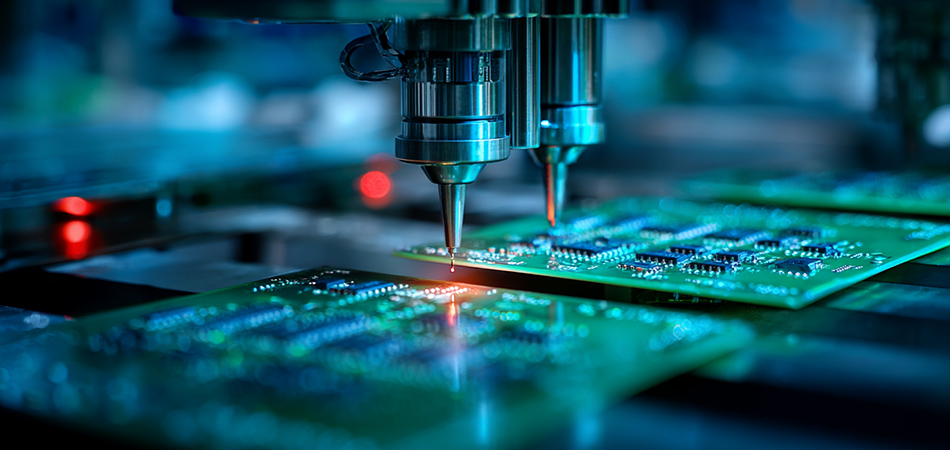

Solder Quality: Automated soldering processes with real-time inspection (e.g., AOI—Automated Optical Inspection) ensure consistent, defect-free joints, critical for electrical conductivity and mechanical strength.

Cleanroom Production: Dust and particle control in manufacturing environments prevents contaminants from compromising PCB performance, especially in sensitive ADAS components.

Applications of IATF 16949 Certified Auto PCBs

Certified PCBs are integral to nearly all modern automotive systems, particularly those critical to safety and performance:

Safety-Critical Systems

Advanced Driver-Assistance Systems (ADAS): PCBs power radar, LiDAR, and camera modules, enabling features like adaptive cruise control, automatic emergency braking, and lane-keeping assist. IATF 16949 ensures these PCBs deliver consistent performance, as failures could lead to accidents.

Braking and Steering Electronics: Anti-lock braking systems (ABS) and electric power steering (EPS) rely on certified PCBs to process sensor data and control actuators, with zero tolerance for defects.

Electric and Hybrid Vehicle (EV/HEV) Systems

Battery Management Systems (BMS): PCBs monitor and balance battery cells in EVs, preventing overcharging or overheating. Certification ensures accuracy in voltage and temperature sensing, critical for battery safety and longevity.

Inverters and Motor Controls: High-power PCBs convert DC power from batteries to AC for electric motors, withstanding high currents and thermal stress. IATF 16949 ensures these PCBs meet strict efficiency and reliability standards.

Comfort and Connectivity

Infotainment and Telematics: PCBs in touchscreens, navigation systems, and vehicle-to-everything (V2X) communication modules require stable performance in cabin environments. Certification ensures resistance to temperature fluctuations and vibration-induced signal loss.

Lighting Systems: LED headlights, taillights, and interior lighting rely on PCBs to manage power and dimming. Certified PCBs ensure consistent brightness and longevity, reducing warranty claims.

Quality Management in IATF 16949 Certified PCB Manufacturing

IATF 16949’s quality management system (QMS) drives every stage of auto PCB production, from design to delivery:

Design for Manufacturability (DFM) and Design for Assembly (DFA)

Cross-Functional Collaboration: Engineers, manufacturers, and OEM representatives collaborate early in design to identify potential issues (e.g., difficult soldering points, material incompatibilities), reducing costly reworks later.

Failure Mode and Effects Analysis (FMEA): Teams proactively identify risks (e.g., PCB warpage, trace corrosion) and implement design changes (e.g., thicker copper traces, protective coatings) to prevent failures.

Production Process Controls

Statistical Process Control (SPC): Real-time monitoring of production parameters (e.g., lamination temperature, solder paste application) ensures processes stay within acceptable limits, reducing variability.

Automated Inspection: AOI and X-ray inspection systems detect defects (e.g., short circuits, missing solder) that manual checks might miss, ensuring only compliant PCBs proceed to assembly.

Post-Production Validation

Environmental Testing: PCBs undergo thermal cycling (rapid temperature changes), vibration testing (simulating road conditions), and humidity testing to validate performance under stress.

Reliability Testing: Long-term endurance tests (e.g., extended operation at high temperatures) predict lifespan and performance degradation, ensuring PCBs meet automotive durability requirements (often 10+ years).

Benefits of IATF 16949 Certification for Stakeholders

For Automotive OEMs

Reduced Risk of Recalls: Certified PCBs minimize defect rates, lowering the likelihood of safety-related recalls that damage brand reputation and incur high costs.

Supply Chain Confidence: Certification ensures consistent quality across PCB suppliers, simplifying qualification and reducing audit burdens.

Alignment with Safety Standards: Compliance with IATF 16949 supports adherence to global automotive safety regulations (e.g., ISO 26262 for functional safety).

For PCB Manufacturers

Market Access: IATF 16949 certification is a prerequisite for supplying to major automakers, opening doors to the lucrative automotive electronics market.

Operational Efficiency: Standardized processes reduce waste, reworks, and downtime, improving productivity and profitability.

Enhanced Customer Trust: Certification signals a commitment to quality, strengthening relationships with automotive clients.

For End Users (Drivers and Fleet Operators)

Improved Vehicle Safety: Certified PCBs reduce the risk of electronic failures in safety systems, enhancing driver and passenger protection.

Longer Vehicle Lifespan: Reliable PCBs extend the life of critical components, reducing maintenance costs and improving resale value.

Consistent Performance: Vehicles with certified PCBs deliver stable performance in diverse conditions, from extreme weather to rough terrain.

Trends Shaping IATF 16949 Certified Auto PCBs

Electrification and High-Voltage PCBs

As EV adoption grows, demand for IATF 16949 certified high-voltage PCBs (used in inverters, chargers) is rising. These PCBs require enhanced insulation, thermal management, and safety features, with certification ensuring compliance with EV-specific standards.

Integration of Advanced Technologies

ADAS and Autonomy: PCBs for Level 3+ autonomous vehicles require higher precision and reliability, with IATF 16949 driving stricter controls on signal integrity and sensor connectivity.

5G and V2X Communication: PCBs supporting high-speed data transmission in connected cars need low-loss materials and tight manufacturing tolerances, validated through certification.

Sustainability in Manufacturing

IATF 16949 certified manufacturers are increasingly integrating sustainability into PCB production:

Eco-Friendly Materials: Use of halogen-free substrates and lead-free solders aligns with automotive OEMs’ carbon-neutral goals.

Energy-Efficient Processes: Adoption of renewable energy and waste-reduction measures in manufacturing supports global sustainability targets.

Conclusion

IATF 16949 certified auto PCBs are the backbone of modern automotive electronics, ensuring safety, reliability, and performance in vehicles worldwide. By adhering to rigorous quality management standards, these PCBs meet the unique challenges of automotive environments—from extreme temperatures to vibration—while enabling innovations in electrification, autonomy, and connectivity. For OEMs, certification reduces risk and ensures supply chain consistency; for manufacturers, it unlocks market opportunities and operational efficiency; for drivers, it delivers safer, more durable vehicles. As automotive technology advances, IATF 16949 certified auto PCBs will remain critical to translating innovation into real-world reliability, driving the future of mobility.

Keywords: IATF 16949 Certified Auto PCB, automotive electronics, quality management, ADAS, EV PCBs, automotive reliability, ISO 26262, PCB manufacturing.

This article provides a technical and industry-focused overview of IATF 16949 certified auto PCBs, emphasizing their role in automotive safety and innovation while optimizing for search engine visibility through relevant keywords and structured content.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB