-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 01. 2025, 15:01:59

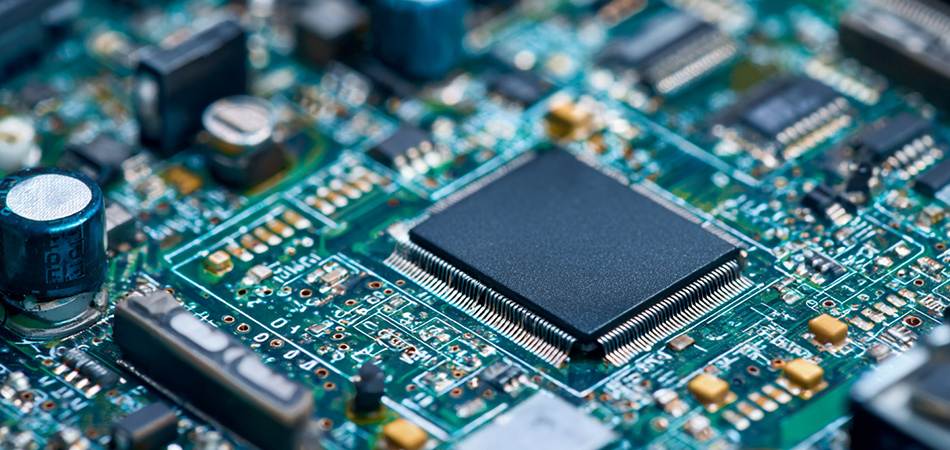

The Beacon of Quality: A Glimpse into Certified Excellence

In the bustling world of electronic manufacturing, where precision and reliability are non-negotiable, ISO 9001-certified aluminum PCB suppliers stand as beacons of quality. Imagine a sprawling factory bathed in the glow of precision instruments, where every sheet of aluminum undergoes a transformation guided by meticulous processes. These suppliers are the silent guardians of electronic integrity, their facilities humming with the rhythm of standardized excellence. From the moment raw materials enter their gates to the final shipment of finished PCBs, every step is a testament to their commitment to the ISO 9001 framework—a commitment that ripples through global supply chains, powering everything from everyday devices to advanced aerospace systems.

The Significance of Certification: A Stamp of Trust in Metal and Circuitry

A Global Language of Quality Assurance

ISO 9001 is more than a certification; it's a universal language of quality. For aluminum PCB suppliers, earning this certification is like receiving a master craftsman's seal, signaling to clients worldwide that their processes are not just efficient, but inherently reliable. Picture a team of engineers poring over detailed blueprints, ensuring that every lamination, every etch, and every test adheres to international standards. This isn't just manufacturing—it's a disciplined art form, where consistency is king and every batch of PCBs is a replica of the last in both quality and performance.

Why Certification Matters: Beyond the Surface of Circuit Boards

In the high-stakes realm of electronics, where a single flaw can render a device useless, ISO 9001 certification is the ultimate risk mitigation strategy. Envision a network of digital records tracing the journey of a single aluminum sheet—from its origin as raw metal to its role as a vital PCB component. Certified suppliers maintain such meticulous records, ensuring that every copper trace, every dielectric layer, and every thermal via can be tracked and verified. This traceability isn't just about compliance; it's about building trust—a trust that allows clients to rest easy, knowing their critical components have been crafted in an environment where quality is non-negotiable.

The Certification Journey: From Chaos to Controlled Excellence

The path to ISO 9001 certification is a transformative journey for any supplier. Imagine a manufacturing floor before certification—chaotic, inconsistent, and prone to errors. Now, visualize the same floor after implementing ISO 9001: order prevails, processes are documented, and every operator knows their role in the quality ecosystem. The certification process itself is a rigorous adventure: gap analyses reveal hidden inefficiencies, system implementations bring order to chaos, third-party audits provide unbiased validation, and continuous surveillance ensures that complacency never creeps in. It's a journey that turns good suppliers into great ones, and great ones into industry leaders.

The Inner Workings of a Certified Quality Ecosystem

The Paper Trail: Documentation as the Foundation of Excellence

ISO 9001-certified suppliers are masters of documentation, maintaining a library of records that would make any archivist proud. Picture a quality manual as the blueprint of their operations, outlining policies that guide every decision. Process maps lay out the manufacturing journey like a detailed roadmap, while work instructions serve as step-by-step guides for operators—think of them as the recipes in a master chef's cookbook, ensuring that every "dish" (or PCB) is prepared to perfection. This documentation isn't just busywork; it's the backbone of consistency, allowing new team members to quickly grasp standards and experienced ones to stay on track.

Material Management: A Symphony of Sourcing and Inspection

The Art of Supplier Evaluation

Certified suppliers approach material sourcing with the discernment of a connoisseur. Envision a team evaluating potential raw material suppliers like judges in a competition—assessing quality, reliability, and compliance with the scrutiny of eagle eyes. They don't just buy materials; they forge partnerships with suppliers who share their commitment to excellence. This careful selection ensures that every aluminum alloy, every copper foil, and every dielectric compound meets the stringent standards required for high-performance PCBs.

Digital Traceability: The GPS of Material Journey

In the digital age, certified suppliers have upgraded from paper trails to digital ones. Imagine a vast database where every material lot is assigned a unique identifier, allowing it to be tracked through every stage of production. This isn't just about record-keeping; it's about creating a digital twin of every PCB, enabling quick recalls if needed and providing clients with peace of mind. It's like having a GPS for every component, ensuring that nothing is lost or forgotten in the manufacturing maze.

Manufacturing Mastery: Where Precision Meets Process

The Statistical Safety Net

Certified suppliers don't leave quality to chance—they use statistics as their safety net. Picture a control room where screens display real-time data on production variables, with algorithms alerting operators to even the slightest deviations. This is Statistical Process Control (SPC) in action—a method that turns manufacturing into a science. Key Performance Indicators (KPIs) act as the scorecards, tracking everything from first-pass yield to defect rates, driving continuous improvement like a coach pushing a team to excellence.

The Maintenance Maestros

In the world of ISO 9001, equipment isn't just tools; it's cherished instruments. Imagine a team of maintenance technicians treating manufacturing equipment with the care of a piano tuner—scheduling preventive maintenance like rehearsals, ensuring that every laminator, drill press, and etching system is in perfect tune. Calibration programs act as the annual check-ups, ensuring that testing instruments are as accurate as a surgeon's scalpel. This dedication to equipment care ensures that every PCB is crafted with the same precision, batch after batch.

The Testing Gauntlet: Where PCBs Prove Their Worth

In-Process Vigilance

As PCBs make their way through the manufacturing line, they encounter vigilant inspectors—both human and machine. Envision trained operators with eagle eyes, meticulously checking for defects at key stages, while Automated Optical Inspection (AOI) systems act as robotic assistants, using advanced imaging to detect flaws invisible to the naked eye. This dual approach ensures that even the tiniest imperfection is caught before it can compromise the final product.

3.4.2 The Final Trials

Before a PCB earns its place in a final product, it must pass a series of rigorous trials. Electrical testing ensures that circuits are as reliable as a well-oiled machine, while thermal performance testing simulates the heat stress of real-world use. Environmental testing is the ultimate challenge—imagine PCBs being subjected to extreme temperatures, humidity, and vibration, all to ensure they can withstand the harshest conditions. Only those that emerge victorious from this gauntlet are deemed worthy of leaving the facility.

Customer-Centricity: Beyond Manufacturing to Partnership

The Consultative Approach

Certified suppliers don't just build PCBs; they build partnerships. Envision a team of experts sitting across from a client, not just taking orders but actively listening to their needs—like architects understanding a client's vision before designing a building. Design reviews are collaborative sessions where ideas flow, ensuring that PCBs are not just manufactured but optimized for performance and manufacturability.

The After-Sales Support System

The relationship doesn't end with delivery; it evolves into a long-term partnership. Imagine a dedicated support team ready to assist with integration challenges, like a tech support hotline for critical components. Feedback collection is ongoing, turning client insights into opportunities for improvement—because for certified suppliers, the journey to excellence is never complete.

The Benefits: A Ripple Effect of Quality

The Assurance of Excellence

Partnering with an ISO 9001-certified supplier is like having a quality insurance policy. Envision a production line where defect rates are as rare as a perfect score in a gymnastics competition, where every PCB meets specifications with the precision of a Swiss watch. This consistency isn't just about meeting standards; it's about exceeding expectations, ensuring that end products are reliable even in the most demanding environments.

Mitigating Risks in a Complex World

In today's globalized supply chains, risks are ever-present—but certified suppliers are masters at risk mitigation. Picture a well-orchestrated logistics system that navigates disruptions with the agility of a chess grandmaster, ensuring that deliveries are on time and materials are compliant with international standards. This isn't just about avoiding problems; it's about protecting clients from costly recalls and legal issues, allowing them to focus on what they do best.

Efficiency as a Competitive Edge

ISO 9001 isn't just about quality; it's about efficiency. Imagine a manufacturing process where rework is as rare as a solar eclipse, where time to market is accelerated by streamlined processes. Certified suppliers turn efficiency into a competitive edge, offering competitive pricing without compromising on quality—like a high-end restaurant that serves gourmet meals at reasonable prices.

Innovation Fueled by Discipline

Contrary to popular belief, ISO 9001 doesn't stifle innovation—it fuels it. Envision a research lab where scientists are free to explore new materials and technologies, but with the discipline to document every step. This controlled innovation ensures that new ideas are not just novel but also reliable, leading to breakthroughs like nano-composite dielectrics and recycled aluminum substrates that push the boundaries of what's possible.

Illuminating Industries: Where Certified PCBs Shine

Lighting Up the World

ISO 9001-certified PCBs are the unsung heroes of modern lighting. Picture city streets bathed in the even glow of LED streetlights, their longevity ensured by reliable thermal management. Imagine architectural marvels transformed by dynamic lighting displays, or the safety provided by consistent automotive headlights—all made possible by PCBs that meet the highest quality standards.

Powering the Future

In the realm of power electronics and renewable energy, certified PCBs are the engines of innovation. Envision solar inverters converting sunlight to electricity with maximum efficiency, or electric vehicle charging stations that rely on robust thermal management. These PCBs aren't just components; they're enablers of a sustainable future.

The Electronics That Define Our Lives

From the smartphone in your pocket to the smart home devices that make life easier, certified PCBs are at the heart of modern living. Imagine the slim design of a tablet made possible by reliable thermal performance, or the durability of IoT sensors that monitor everything from health to environmental conditions. These PCBs are the invisible threads that weave our digital world together.

Advancing Healthcare and Aerospace

In industries where reliability is a matter of life and death, certified PCBs are the gold standard. Picture the precision of medical diagnostic equipment, or the consistent illumination in surgical rooms. Envision avionics systems guiding aircraft safely through the skies, or satellite technology that communicates across vast distances—all relying on PCBs that have passed the most rigorous quality tests.

Choosing a Partner: A Guide to Selecting Excellence

Verifying the Gold Standard

When selecting an ISO 9001 supplier, certification validity is the first checkpoint. Imagine a detective verifying the credentials of a suspect—except here, you're verifying the credibility of the certification body and the scope of the certification. It's about ensuring that the supplier's certification is not just a piece of paper, but a true reflection of their capabilities.

Assessing Technical Prowess

Technical capabilities are the backbone of any supplier. Envision a tour of a manufacturing facility, where you observe the complexity of PCB designs they can handle, the expertise they offer in design for manufacturability, and the sophistication of their testing facilities. It's like evaluating an artist's studio—assessing their tools, their techniques, and their portfolio.

Navigating Supply Chain Logistics

Logistics can make or break a partnership. Picture a logistics coordinator managing a fleet of trucks, ensuring that materials are delivered on time and inventory is managed efficiently. Assessing a supplier's lead times, inventory management, and global reach is like evaluating a conductor's ability to orchestrate a complex symphony—ensuring that every component arrives when and where it's needed.

Reading the Report Card: Quality Metrics and History

Past performance is often the best predictor of future results. Imagine reviewing a supplier's quality report card—examining metrics like defect rates and customer satisfaction scores, and reading case studies that showcase their capabilities. It's like checking a athlete's stats before drafting them for your team—looking for a proven track record of excellence.

Beyond Quality: Ethical and Environmental Responsibility

In today's world, responsibility extends beyond quality. Envision a supplier that not only meets ISO 9001 but also prioritizes environmental sustainability and ethical manufacturing. It's like choosing a restaurant that not only serves great food but also sources ingredients responsibly—making a choice that aligns with your values.

The Catalyst for Innovation: How ISO 9001 Drives Progress

A Culture of Continuous Improvement

ISO 9001 instills a culture where complacency is forbidden. Imagine a team of engineers constantly brainstorming ways to improve processes, like a sports team that's always training to get better. This culture drives the adoption of new technologies, from 3D printing to AI-driven quality control, and fuels innovation in materials like nano-composites and recycled aluminum—because for certified suppliers, good is never good enough.

Fostering Collaboration for Greater Good

Certified suppliers don't work in isolation; they collaborate to drive industry forward. Envision a summit where suppliers, clients, and researchers come together to share ideas—like a think tank for electronics. These collaborations lead to standardization efforts that benefit the entire industry, pushing the boundaries of what's possible in aluminum PCB technology.

Adapting to the Future: Preparing for What's Next

As technology evolves, so do certified suppliers. Imagine a research lab where scientists are already working on PCBs for 5G and IoT applications, or developing solutions for electric vehicles and renewable energy. These suppliers aren't just keeping up with trends; they're anticipating them, ensuring that their clients are always one step ahead.

Overcoming Hurdles: The Challenges of Sustained Excellence

Dancing with Change: Adapting to Evolving Demands

In a world where change is the only constant, certified suppliers must be agile. Picture a chameleon changing its colors to blend in with its environment—except here, suppliers are adapting their QMS to meet changing customer needs and industry standards. It's a delicate dance, but one that ensures they remain relevant in an ever-evolving landscape.

Balancing Act: Innovating Without Compromising Consistency

Innovation and consistency can be conflicting goals, but certified suppliers have mastered the balancing act. Envision a tightrope walker adding new tricks to their routine while maintaining balance—suppliers implement controlled innovation processes, conducting thorough risk assessments and training staff to ensure that new technologies enhance rather than compromise quality.

Navigating the Supply Chain Maze: Maintaining Continuity

Global supply chains are complex and vulnerable to disruptions. Imagine a ship captain navigating through stormy seas—suppliers diversify their suppliers, implement robust inventory management, and develop contingency plans to ensure that material availability and production continuity are never compromised.

The Human Element: Nurturing Talent for Sustained Quality

At the heart of every certified supplier is a team of skilled professionals. Picture a gardener nurturing a garden—suppliers invest in employee training and development, foster a culture of quality, and offer competitive compensation to ensure that they attract and retain the best talent. Because in the end, quality is a human endeavor, driven by dedicated individuals.

Conclusion: The Enduring Value of Certified Excellence

ISO 9001-certified aluminum PCB suppliers are more than just manufacturers; they're guardians of quality in an increasingly complex world. From the precision of their processes to the reliability of their products, they serve as the foundation upon which modern electronics are built. As technology continues to advance and global demands grow, their role becomes ever more vital—ensuring that the components that power our lives are not just functional, but truly exceptional.

The next time you switch on a LED light, charge your electric vehicle, or use a sophisticated medical device, take a moment to appreciate the invisible hero behind it all: an ISO 9001-certified aluminum PCB, crafted with care, precision, and an unwavering commitment to excellence. These suppliers may work behind the scenes, but their impact is felt everywhere, illuminating our world and powering the future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB