-

- PCB TYPE

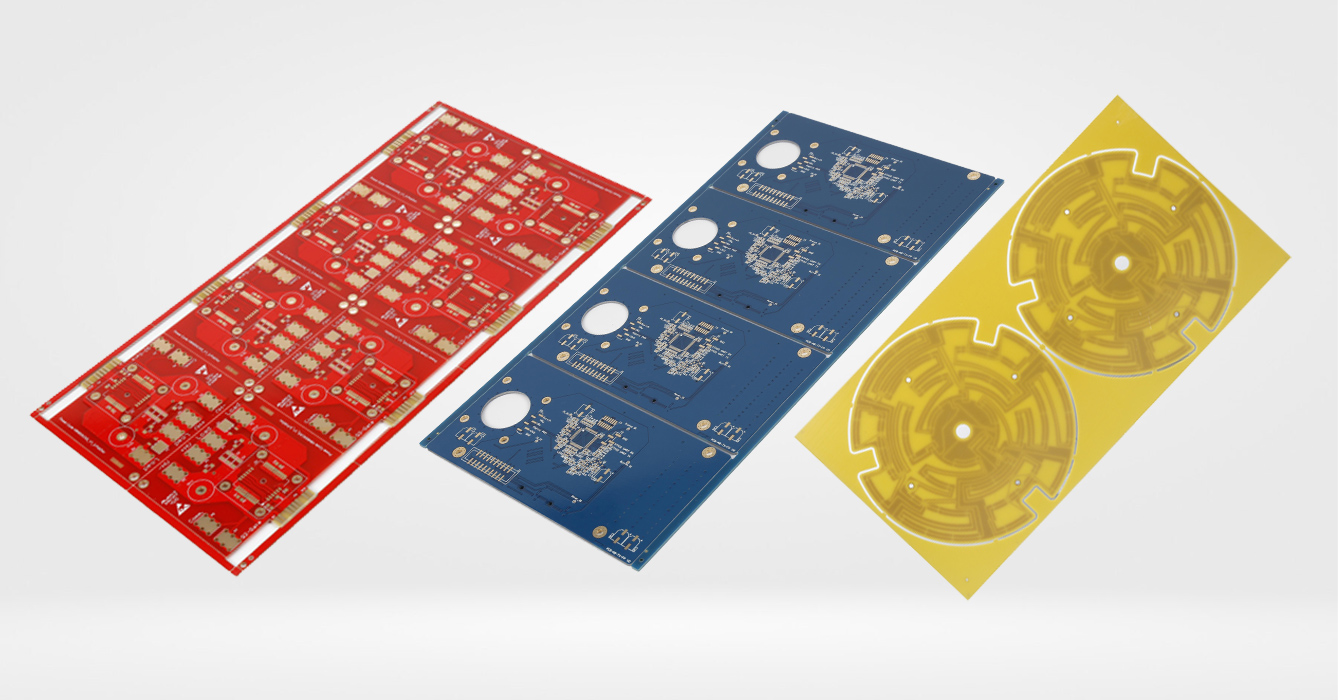

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 28. 2025, 09:47:58

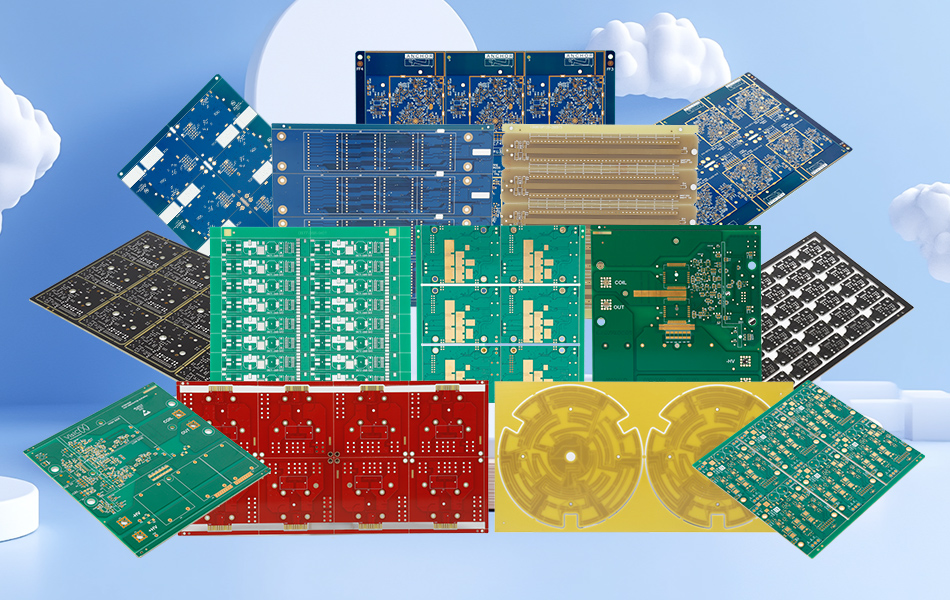

In the competitive landscape of electronics manufacturing, ISO 9001 FR4 PCB Manufacturers stand out as benchmarks of quality, reliability, and consistency. By adhering to the globally recognized ISO 9001 quality management system, these manufacturers integrate rigorous quality controls into every stage of FR4 PCB production—from material sourcing to final inspection. FR4 PCBs, built on glass-reinforced epoxy substrates, remain the industry standard for diverse applications, and ISO 9001 certification ensures they meet stringent performance and reliability requirements. This article explores the role of ISO 9001 in FR4 PCB manufacturing, key quality processes, industry advantages, and the value of certification for customers and markets, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Understanding ISO 9001 in FR4 PCB Manufacturing

ISO 9001 is a globally accepted standard for quality management systems (QMS), focusing on customer satisfaction, process efficiency, and continuous improvement. For FR4 PCB manufacturers, certification means embedding quality into every aspect of operations, from design collaboration to post-delivery support:

Core Principles of ISO 9001 for PCB Manufacturing

Customer-Centric Focus: ISO 9001 requires manufacturers to identify and meet customer requirements, translating into FR4 PCBs tailored to application needs—whether high-density designs for consumer electronics or ruggedized boards for industrial use.

Process Standardization: Documented procedures for every production stage, from material incoming inspection to final testing, ensure consistency across batches, reducing variability and defects.

Continuous Improvement: A structured approach to monitoring, measuring, and enhancing processes through data analysis and corrective actions, driving long-term quality gains.

Risk-Based Thinking: Proactive identification and mitigation of risks in production, such as material defects, process deviations, or supply chain disruptions, ensuring uninterrupted quality.

These principles transform FR4 PCB manufacturing from a reactive process to a proactive system, where quality is built into designs and processes rather than inspected into final products.

Quality Processes in ISO 9001 FR4 PCB Manufacturing

ISO 9001-certified manufacturers implement rigorous quality controls throughout the FR4 PCB production lifecycle:

Material Sourcing and Incoming Inspection

Supplier Qualification: ISO 9001 mandates formalized supplier evaluation and approval processes. Manufacturers audit raw material suppliers (e.g., FR4 substrates, copper foil, solder masks) for quality consistency, traceability, and compliance with industry standards. Only approved suppliers are used to ensure material reliability.

Incoming Material Testing: Every batch of FR4 substrate, copper foil, and chemicals undergoes inspection for properties like dielectric strength, copper purity, and dimensional stability. Non-conforming materials are rejected, preventing downstream defects.

Production Process Control

Documented Work Instructions: Detailed procedures guide operators through lamination, etching, drilling, and plating processes, ensuring uniformity across shifts and operators. ISO 9001 requires these instructions to be regularly reviewed and updated based on process data.

Statistical Process Control (SPC): Key production parameters (e.g., lamination temperature, etching time, drill accuracy) are monitored in real-time using SPC tools. Deviations from control limits trigger immediate corrective actions, preventing defects before they occur.

In-Process Inspection: Automated optical inspection (AOI) and manual checks at critical stages (e.g., after etching, before lamination) verify circuit accuracy, trace integrity, and layer alignment, ensuring compliance with design specifications.

Final Testing and Validation

Electrical Performance Testing: 100% of finished FR4 PCBs undergo continuity, isolation, and impedance testing to ensure electrical functionality. Flying probe or bed-of-nails testers validate connections and detect short circuits or open traces.

Mechanical and Environmental Validation: Samples from each batch are tested for mechanical strength (e.g., peel strength of copper layers), thermal resistance, and humidity resistance, ensuring durability in end-use environments.

Traceability and Documentation: ISO 9001 requires full traceability from raw materials to finished products. Each PCB is labeled with batch numbers, enabling tracking of materials, production dates, and test results for accountability and root cause analysis.

Advantages of Partnering with an ISO 9001 FR4 PCB Manufacturer

Customers benefit significantly from working with ISO 9001-certified FR4 PCB manufacturers, as certification guarantees a focus on quality, reliability, and customer satisfaction:

Consistent Product Quality

ISO 9001’s emphasis on process standardization ensures minimal variability between PCB batches. This consistency is critical for customers in industries like automotive, medical, and aerospace, where component interchangeability and reliability are non-negotiable.

Enhanced Risk Mitigation

By proactively identifying and mitigating risks, ISO 9001 manufacturers reduce the likelihood of defects, delays, or non-conformities. This minimizes rework, scrap, and production downtime for customers, lowering total cost of ownership.

Regulatory Compliance and Market Access

ISO 9001 certification aligns with global regulatory requirements for electronics in sectors like medical devices (ISO 13485) and automotive (IATF 16949). Partnering with a certified manufacturer simplifies customer compliance with these standards, facilitating market access.

Customer-Centric Improvement

ISO 9001 requires manufacturers to collect and analyze customer feedback, using it to drive process improvements. This ensures manufacturers adapt to evolving customer needs, whether for higher-density designs, faster turnaround times, or specialized surface finishes.

Industry Applications of ISO 9001-Certified FR4 PCBs

ISO 9001 FR4 PCBs are trusted in industries where quality and reliability directly impact safety, performance, and compliance:

Medical Electronics

In diagnostic equipment, patient monitors, and wearable health devices, ISO 9001-certified FR4 PCBs ensure consistent performance and traceability, critical for regulatory compliance (e.g., FDA, CE) and patient safety.

Automotive Electronics

Automotive control modules, infotainment systems, and sensor interfaces rely on ISO 9001 FR4 PCBs for durability in harsh environments (temperature extremes, vibration). Certification aligns with IATF 16949 requirements, ensuring quality in automotive supply chains.

Industrial Automation

Industrial controllers, robotics, and IoT sensors use ISO 9001-certified FR4 PCBs for reliable operation in factory environments. Consistent quality minimizes downtime in production lines, where equipment failure can be costly.

Consumer Electronics

High-volume consumer devices like smartphones, laptops, and home appliances benefit from the cost-efficiency and quality consistency of ISO 9001 FR4 PCBs, ensuring reliable performance and customer satisfaction.

The Value of ISO 9001 in Continuous Improvement

ISO 9001 is not a one-time certification but a framework for ongoing improvement. Certified FR4 PCB manufacturers leverage the standard to:

Root Cause Analysis and Corrective Actions

When defects or deviations occur, ISO 9001 requires systematic root cause analysis (e.g., using tools like 5 Whys or Fishbone Diagrams) and implementation of corrective and preventive actions (CAPA). This prevents recurrence and drives process maturity.

Employee Training and Competence

ISO 9001 mandates regular training for operators and engineers on quality processes, equipment operation, and defect prevention. This builds a quality-focused culture, ensuring all employees understand their role in maintaining standards.

Benchmarking and Best Practices

Certified manufacturers participate in industry audits and benchmarking, adopting best practices from peers and updating their QMS to reflect technological advancements (e.g., AI-driven inspection, sustainable materials) in FR4 PCB manufacturing.

Conclusion

ISO 9001 FR4 PCB Manufacturers represent the gold standard in electronics manufacturing, where quality is embedded into every process from material sourcing to final delivery. By adhering to ISO 9001’s principles of process control, risk mitigation, and continuous improvement, these manufacturers deliver FR4 PCBs with consistent performance, reliability, and traceability—critical for industries demanding excellence. For customers, partnering with an ISO 9001-certified manufacturer ensures not just compliant products, but a collaborative relationship focused on mutual success and long-term quality improvement. As electronics grow more complex, the role of ISO 9001 in ensuring FR4 PCB quality will only become more indispensable.

Keywords: ISO 9001 FR4 PCB Manufacturer, quality management system, FR4 PCB quality, certified PCB manufacturing, process control, electronics quality, ISO 9001 compliance, PCB traceability.

This article provides a technically focused overview of ISO 9001 FR4 PCB manufacturers, emphasizing the intersection of quality management and PCB production while ensuring originality, industry relevance, and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB