-

- PCB TYPE

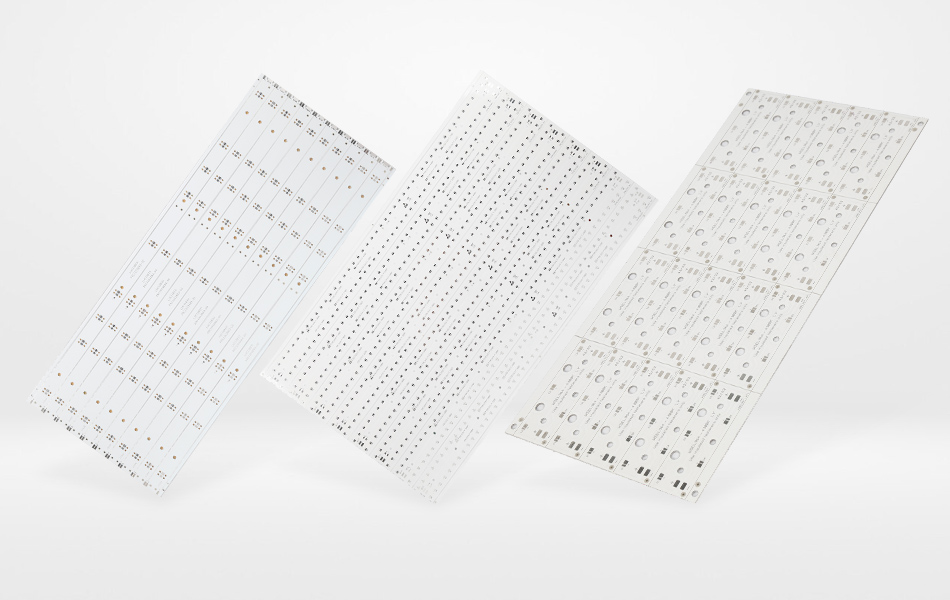

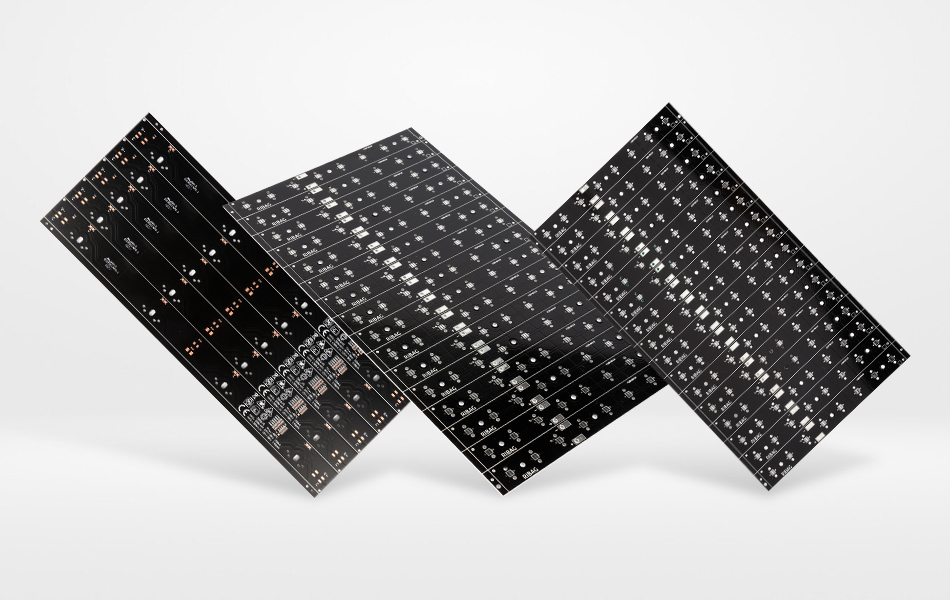

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 10. 2025, 09:15:06

In the dynamic realm of LED lighting, the quest for efficiency, reliability, and longevity has led to the emergence of specialized printed circuit boards (PCBs). Among these, LED lighting aluminum PCBs with a specific copper thickness, often referred to as 2oz, have carved a niche for themselves, offering a unique blend of electrical conductivity, thermal management, and mechanical robustness. This article delves deep into the intricacies of LED lighting aluminum PCBs with this particular copper thickness, exploring their material science, design principles, manufacturing processes, and diverse applications, while highlighting their role in driving the evolution of modern illumination systems.

Material Science Underpinning LED Lighting Aluminum PCBs 2oz

Aluminum Substrate: The Thermal Pillar

The aluminum substrate forms the very foundation of these PCBs, providing a multitude of benefits crucial for LED lighting applications. Its exceptional thermal conductivity serves as a rapid pathway for dissipating the heat generated by LED arrays. In LED lighting, where overheating can lead to significant performance degradation, such as lumen depreciation and color shift, the aluminum substrate's ability to efficiently transfer heat away from the LEDs is indispensable. Moreover, aluminum alloys, known for their favorable strength-to-weight ratio, offer mechanical stability. This allows the PCB to withstand the rigors of various environments, from the vibrations in automotive lighting setups to the temperature fluctuations in outdoor fixtures, ensuring the integrity of the LED components mounted on it.

Dielectric Layers: Balancing Act

Sandwiched between the aluminum substrate and the copper layers, the dielectric layers play a vital dual role. On one hand, they act as insulators, preventing electrical short circuits between the aluminum core and the copper conductive pathways, thus maintaining the electrical integrity of the PCB. On the other hand, they are engineered to have high thermal conductivity, facilitating the efficient transfer of heat from the LEDs to the aluminum substrate. This delicate balance between electrical insulation and thermal conductivity is optimized to ensure that the LED lighting system operates at peak efficiency, with minimal heat buildup and maximum electrical reliability.

Copper Layers: The 2oz Advantage

The 2oz copper thickness is a defining characteristic of these PCBs, offering distinct advantages for LED lighting. Copper, renowned for its low electrical resistance, serves as the conductive medium for both power and signal transmission. With this specific thickness, the copper layers are capable of handling higher currents required by LED clusters without significant resistance-induced heat generation. This reduction in heat generation within the copper traces not only enhances the electrical efficiency of the PCB but also contributes to the overall thermal management of the LED lighting system. Additionally, the 2oz copper thickness provides a robust foundation for soldering LED components, ensuring reliable mechanical and electrical connections that can withstand the demands of continuous operation.

Design Principles for Peak LED Lighting Performance

Thermal Management Strategies

Effective thermal management is the cornerstone of successful LED lighting design, and aluminum PCBs with 2oz copper layers are designed with this in mind. LEDs are strategically placed on the PCB to maximize contact with the aluminum substrate, enabling direct heat transfer. Thermal vias, carefully positioned beneath each LED, create additional pathways for heat to flow from the copper layers to the aluminum core, further enhancing heat dissipation. In high-power LED applications, where heat accumulation can be a significant issue, the combination of the aluminum substrate's thermal conductivity and the 2oz copper layers' ability to handle current efficiently ensures that the LEDs operate within their optimal temperature range, extending their lifespan and maintaining consistent light output.

Electrical Design Considerations

The electrical design of these PCBs is tailored to meet the specific requirements of LED lighting systems. The 2oz copper layers are patterned to create dedicated power and signal traces. Power traces are designed to carry the high currents necessary to drive the LED arrays, with a focus on minimizing voltage drops and ensuring uniform power distribution across all LEDs. Signal traces, on the other hand, are carefully routed to transmit control signals for functions such as dimming and color adjustment, maintaining signal integrity to enable precise control of the LED lighting. Additionally, the PCB layout incorporates grounding strategies to minimize electromagnetic interference (EMI), which can disrupt the operation of LED drivers and other electronic components in the system.

Mechanical and Optical Design Integration

In LED lighting, the mechanical and optical aspects of the PCB design are closely intertwined with its electrical and thermal performance. The flat and stable surface provided by the aluminum substrate with 2oz copper layers allows for precise placement of LEDs, ensuring consistent light distribution and accurate beam angles. This is particularly important in applications such as architectural lighting, where the visual appeal and uniformity of the illumination are critical. Moreover, the formability of the aluminum substrate enables the creation of custom-shaped PCBs that can be seamlessly integrated into various lighting fixtures, from sleek and modern recessed downlights to elaborate outdoor signage, without compromising on thermal or electrical performance.

Manufacturing Processes for Precision and Quality

Substrate Preparation

The manufacturing process of LED lighting aluminum PCBs 2oz begins with the preparation of the aluminum substrate. Precision cutting techniques, such as CNC milling or laser cutting, are employed to achieve exact dimensions, ensuring a perfect fit within the intended lighting fixtures. Subsequently, the substrate undergoes surface treatments, including degreasing and micro-etching. These treatments enhance the adhesion of the dielectric layers, creating a strong bond that is essential for maintaining the integrity of the PCB's thermal and electrical performance.

Layer Lamination

The next crucial step is the lamination of the dielectric layers to the aluminum substrate. High-pressure lamination processes are utilized to bond the dielectric materials firmly, creating a uniform thermal interface. This step requires meticulous control of temperature and pressure to ensure that the dielectric layers adhere evenly across the entire surface of the aluminum substrate, preventing any potential hotspots or thermal inefficiencies in the final PCB.

Copper Layer Fabrication

Fabricating the 2oz copper layers involves several intricate processes. First, the copper foil is laminated onto the dielectric layers. Photolithography or laser direct imaging (LDI) techniques are then used to transfer the circuit patterns onto the copper foil with high precision. Chemical etching follows, selectively removing the unwanted copper to create the desired conductive traces. Automated optical inspection (AOI) systems are employed at this stage to meticulously check for any defects in the copper traces, such as bridging or thinning, ensuring the electrical reliability of the PCB.

Surface Finishing and Component Assembly

To enhance the solderability of the copper traces and protect them from corrosion, surface finishes such as electroless nickel immersion gold (ENIG) or organic solderability preservative (OSP) are applied. Once the surface finishing is complete, the LED components are assembled onto the PCB using high-precision pick-and-place machines. Reflow soldering processes are carefully calibrated to ensure strong and reliable solder joints, taking into account the thermal properties of the aluminum substrate and the 2oz copper layers.

Diverse Applications of LED Lighting Aluminum PCBs 2oz

Commercial Lighting

In commercial spaces such as offices, malls, and large retail stores, LED lighting aluminum PCBs 2oz play a pivotal role. They are used in high-brightness LED panels to provide uniform and energy-efficient illumination. The ability of these PCBs to handle high currents and dissipate heat effectively ensures that the LED panels can operate continuously for extended periods without overheating, reducing maintenance costs and ensuring consistent lighting quality. Additionally, their design flexibility allows for the creation of custom lighting solutions that can enhance the aesthetic appeal of the commercial environment while meeting strict energy efficiency standards.

Residential Lighting

For residential applications, these PCBs are integrated into a wide range of lighting fixtures, from recessed downlights to decorative pendant lights. In recessed lighting, the compact design and efficient thermal management of the PCBs enable the creation of slim fixtures that can be easily installed in ceilings. In decorative lighting, the precise control over LED placement and light distribution provided by the PCBs allows for the creation of unique lighting effects that can enhance the ambiance of any living space. Moreover, the reliability and long lifespan of the PCBs ensure that residential lighting systems require minimal upkeep, providing homeowners with hassle-free illumination.

Outdoor Lighting

Outdoor lighting environments pose unique challenges due to exposure to various weather conditions and temperature extremes. LED lighting aluminum PCBs 2oz are well-suited for these applications. In streetlights, parking lot fixtures, and outdoor signage, the mechanical robustness of the aluminum substrate combined with the thermal and electrical performance of the 2oz copper layers ensures reliable operation. The PCBs can withstand the vibrations from traffic, the heat of direct sunlight, and the cold of winter, maintaining consistent light output and protecting the LED components from damage.

Automotive Lighting

In the automotive industry, where space is limited and reliability is of utmost importance, these PCBs are used in headlights, taillights, and interior lighting systems. The 2oz copper layers can handle the high currents required by automotive LEDs, while the aluminum substrate provides excellent thermal management within the confined spaces of vehicle lighting enclosures. This combination ensures that the LED lighting systems in cars, trucks, and other vehicles can operate reliably under a wide range of operating conditions, enhancing visibility and safety on the road.

Emerging Trends and Future Outlook

Miniaturization and High-Density Integration

As the demand for more compact and powerful LED lighting solutions grows, there is a trend towards miniaturization and high-density integration on LED lighting aluminum PCBs 2oz. Advanced manufacturing techniques, such as laser-drilled microvias and fine-pitch trace routing, are being employed to pack more components onto the PCB while maintaining optimal performance. This allows for the creation of smaller, more energy-efficient lighting fixtures that can be integrated into a wider range of applications, from wearable lighting devices to ultra-slim architectural lighting.

Smart Lighting Integration

The rise of smart lighting systems is also influencing the design of these PCBs. LED lighting aluminum PCBs 2oz are being engineered to accommodate embedded microcontrollers, sensors, and wireless communication modules. This integration enables features such as remote control, occupancy sensing, and daylight harvesting, making LED lighting systems more intelligent and energy-efficient. The PCBs' ability to handle the additional electrical demands of these components while maintaining reliable thermal performance is crucial for the successful implementation of smart lighting technologies.

Sustainable Manufacturing Practices

In response to growing environmental concerns, the industry is increasingly adopting sustainable manufacturing practices for LED lighting aluminum PCBs 2oz. This includes the use of recycled materials for the aluminum substrate and copper layers, as well as the implementation of eco-friendly manufacturing processes. Additionally, efforts are being made to improve the energy efficiency of the PCBs themselves, reducing their overall environmental impact while still delivering high-performance lighting solutions.

Conclusion

LED lighting aluminum PCBs 2oz have emerged as a key enabler in the evolution of modern illumination systems. Their unique combination of a thermally conductive aluminum substrate, precisely engineered dielectric layers, and robust 2oz copper layers offers a comprehensive solution for the challenges faced in LED lighting applications. From ensuring efficient thermal management and reliable electrical performance to enabling innovative design and diverse applications, these PCBs play an indispensable role in the lighting industry. As technology continues to advance and new trends emerge, LED lighting aluminum PCBs 2oz are poised to adapt and evolve, driving the development of even more energy-efficient, intelligent, and sustainable lighting solutions that will illuminate our world for years to come.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB