-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 10. 2025, 09:29:13

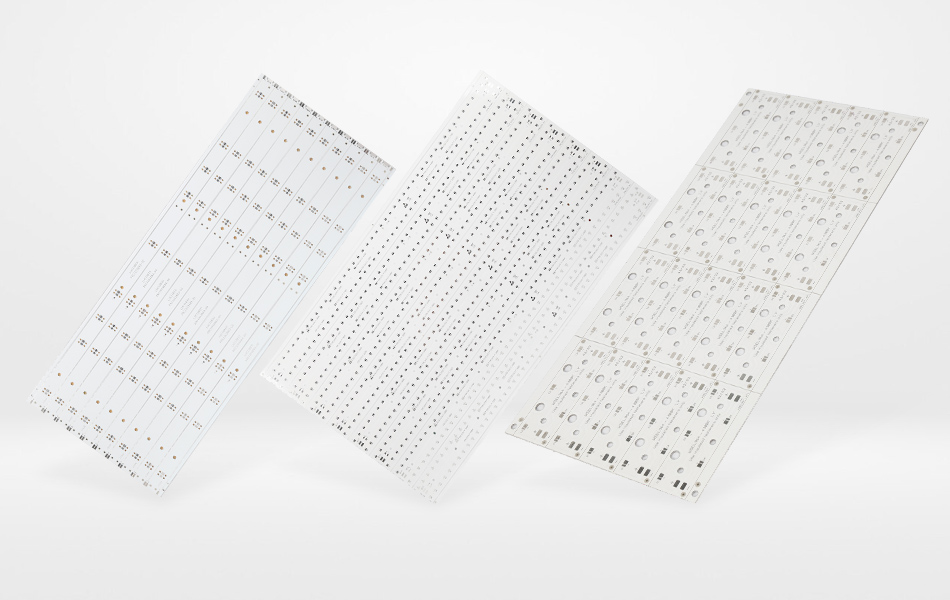

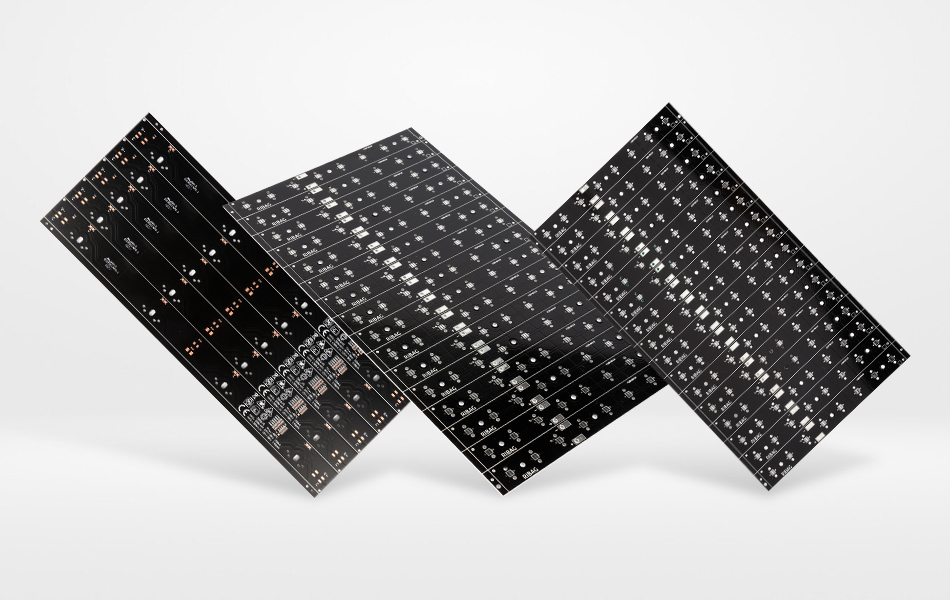

In the ever - advancing domain of lighting technology, LED lighting aluminum printed circuit boards (PCBs) have emerged as a revolutionary force, redefining the boundaries of what is possible in illumination systems. These specialized PCBs combine the unique properties of aluminum with the cutting - edge capabilities of LED technology, offering a comprehensive solution for modern lighting needs. This article takes an in - depth look at LED lighting aluminum PCBs, exploring their fundamental characteristics, design considerations, manufacturing processes, diverse applications, and future trends, highlighting their significance in the lighting industry.

Fundamental Characteristics of LED Lighting Aluminum PCBs

The Role of the Aluminum Substrate

The aluminum substrate in LED lighting PCBs is the cornerstone of their functionality. Its primary role is thermal management. Aluminum's high thermal conductivity allows for rapid heat dissipation from LED components. In LED lighting, excessive heat can lead to a decrease in luminous efficiency, color shift, and ultimately, a shortened lifespan of the LEDs. The aluminum substrate acts as an efficient heat sink, creating a pathway for heat to be transferred away from the LEDs, ensuring they operate within an optimal temperature range. This not only enhances the performance of the LEDs but also contributes to the overall reliability of the lighting system.

Moreover, aluminum substrates offer mechanical stability. They can withstand the rigors of various environments, including vibrations and temperature fluctuations. This makes them suitable for a wide range of applications, from indoor lighting fixtures to outdoor streetlights and automotive lighting systems. The formability of aluminum also allows for the creation of PCBs in various shapes and sizes, enabling designers to meet the specific requirements of different lighting applications.

Dielectric Layers: The Insulation and Thermal Link

Sandwiched between the aluminum substrate and the copper layers, the dielectric layers in LED lighting PCBs serve a dual - purpose. Firstly, they provide electrical insulation, preventing short circuits between the aluminum core and the copper conductive pathways. This is crucial for maintaining the integrity of the electrical signals and power supply to the LEDs.

Secondly, dielectric layers are engineered to have good thermal conductivity. They act as a thermal link, facilitating the transfer of heat from the LEDs to the aluminum substrate. The choice of dielectric material is critical, as it directly impacts the thermal performance of the PCB. High - quality dielectric materials can minimize thermal resistance, ensuring that heat is transferred efficiently and that the LEDs remain cool during operation.

Copper Layers: Conductive Pathways for LED Operation

The copper layers in LED lighting aluminum PCBs are responsible for carrying electrical current to the LEDs. Copper's excellent electrical conductivity makes it an ideal material for this purpose. The copper layers are patterned to create traces that serve as both power and signal pathways.

Power traces are designed to handle the high currents required by LED arrays, ensuring a stable and consistent power supply. Signal traces, on the other hand, are used to transmit control signals for functions such as dimming, color - changing, and communication with smart lighting systems. The design of the copper layers is optimized to minimize electrical resistance, reducing power losses and improving the overall efficiency of the LED lighting system.

Design Considerations for LED Lighting Aluminum PCBs

Thermal Management Design

Thermal management is the most critical aspect of designing LED lighting aluminum PCBs. A well - designed thermal management system ensures that heat is dissipated effectively, preventing overheating of the LEDs. Component placement is a key factor in thermal management. LEDs should be placed in areas that allow for maximum heat transfer to the aluminum substrate. Thermal vias can be strategically placed to connect the copper layers to the aluminum core, providing additional pathways for heat to flow.

In addition, the design may incorporate heat sinks, either integrated with the PCB or as external components. Heat sinks increase the surface area available for heat dissipation, further enhancing the cooling effect. The choice of heat sink material and design depends on the specific requirements of the lighting application, such as the power of the LEDs and the operating environment.

Electrical Design

The electrical design of LED lighting aluminum PCBs focuses on ensuring reliable power delivery and signal transmission. Power distribution networks are designed to provide a stable voltage and current to the LEDs, minimizing voltage drops and ensuring uniform brightness across the LED array.

For smart lighting applications, the PCB design must accommodate the integration of control circuits and communication modules. This requires careful routing of signal traces to prevent electromagnetic interference (EMI) and ensure reliable communication. Grounding strategies are also important in electrical design, as they help to reduce noise and improve the overall performance of the electrical system.

Mechanical and Optical Design

Mechanical design considerations for LED lighting aluminum PCBs include the form factor, mounting options, and structural integrity. The PCB should be designed to fit seamlessly into the lighting fixture, with appropriate mounting holes and features. The mechanical design also needs to ensure that the PCB can withstand the mechanical stresses of installation, operation, and transportation.

Optical design is closely related to the mechanical design of the PCB. The placement and orientation of the LEDs on the PCB determine the light distribution pattern of the lighting fixture. Reflectors, lenses, and diffusers may be integrated with the PCB or the lighting fixture to control the direction and quality of the light output. This is especially important in applications such as architectural lighting, where the aesthetic and functional aspects of the light are equally important.

Manufacturing Processes of LED Lighting Aluminum PCBs

Substrate Preparation

The manufacturing process of LED lighting aluminum PCBs begins with substrate preparation. The aluminum substrate is first cut to the desired size and shape using precision cutting techniques, such as CNC machining or laser cutting. After cutting, the surface of the aluminum substrate undergoes a series of treatments, including cleaning, degreasing, and micro - etching. These surface treatments improve the adhesion of the dielectric layers and enhance the overall performance of the PCB.

Layer Lamination

Once the substrate is prepared, the dielectric layers are laminated onto the aluminum surface. High - pressure lamination processes are used to ensure a strong bond between the dielectric materials and the aluminum substrate. The lamination process requires precise control of temperature, pressure, and time to achieve a uniform and defect - free bond. After the dielectric layers are laminated, the copper layers are then applied using processes such as electroplating or lamination of copper foil.

Circuit Pattern Formation

The next step in the manufacturing process is the formation of the circuit pattern on the copper layers. This is typically done using photolithography or laser direct imaging (LDI). In photolithography, a photosensitive resist is applied to the copper surface, and then exposed to light through a mask with the desired circuit pattern. The exposed resist is then developed, and the unwanted copper is etched away, leaving behind the circuit traces. LDI, on the other hand, directly writes the circuit pattern onto the copper surface using a laser, eliminating the need for a mask.

Surface Finishing and Assembly

After the circuit pattern is formed, the PCB undergoes surface finishing. Surface finishes such as electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), or hot air solder leveling (HASL) are applied to protect the copper traces and improve solderability. Once the surface finishing is complete, the LEDs and other components are assembled onto the PCB using automated pick - and - place machines. Reflow soldering or wave soldering processes are then used to attach the components securely to the PCB, completing the manufacturing process.

Diverse Applications of LED Lighting Aluminum PCBs

Commercial Lighting Applications

In commercial buildings, LED lighting aluminum PCBs are widely used in a variety of applications. In office spaces, they are used in ceiling - mounted fixtures to provide bright, uniform illumination. The energy - efficiency and long lifespan of LED lighting systems based on these PCBs make them a cost - effective choice for commercial property owners, reducing energy consumption and maintenance costs.

In retail stores, LED lighting aluminum PCBs are used in display lighting to highlight products. The ability to control the color temperature and intensity of the light allows retailers to create an attractive shopping environment that enhances the visual appeal of their merchandise. In addition, these PCBs are used in large - scale commercial lighting projects such as shopping malls, airports, and stadiums, where reliable and efficient lighting is essential.

Residential Lighting Applications

For residential use, LED lighting aluminum PCBs are integrated into a wide range of lighting fixtures. Recessed downlights, pendant lights, and track lighting systems often use these PCBs. In residential settings, the energy - saving benefits of LED lighting are highly valued, as they can significantly reduce electricity bills.

Moreover, the design flexibility of LED lighting aluminum PCBs allows for the creation of custom - designed lighting fixtures that can enhance the aesthetic appeal of any home. Smart lighting systems, which can be controlled remotely using smartphones or voice assistants, are also becoming increasingly popular in residential applications, and LED lighting aluminum PCBs play a crucial role in enabling these advanced features.

Outdoor Lighting Applications

Outdoor lighting is another major area where LED lighting aluminum PCBs are utilized. Streetlights, area lights, and landscape lighting all benefit from the use of these PCBs. The ability of aluminum PCBs to withstand harsh outdoor conditions, including extreme temperatures, moisture, and dust, makes them ideal for outdoor applications.

In addition, the energy - efficiency of LED lighting helps to reduce energy consumption in outdoor lighting installations, which is especially important for large - scale projects such as urban street lighting networks. The long lifespan of LED lighting systems also reduces the frequency of maintenance and replacement, saving both time and money for municipalities and property owners.

Automotive Lighting Applications

In the automotive industry, LED lighting aluminum PCBs are used in headlights, taillights, and interior lighting. The compact size and high performance of these PCBs make them suitable for the limited space available in automotive lighting fixtures. The ability to control the light output precisely, such as adjusting the beam pattern in headlights, enhances safety on the road.

The reliability of LED lighting aluminum PCBs is also crucial in automotive applications, as they need to operate consistently under varying conditions, including vibrations from vehicle movement and temperature changes inside and outside the vehicle.

Future Trends in LED Lighting Aluminum PCBs

Integration with Smart Technologies

The future of LED lighting aluminum PCBs lies in their integration with smart technologies. As the Internet of Things (IoT) continues to grow, LED lighting systems are expected to become more intelligent. PCBs will be designed to accommodate sensors, microcontrollers, and wireless communication modules, enabling features such as occupancy sensing, daylight harvesting, and remote control.

Smart lighting systems can automatically adjust the light output based on the presence of people, the time of day, or the amount of natural light available, further enhancing energy savings. In addition, these systems can be integrated with building management systems, providing centralized control and monitoring of the lighting infrastructure.

Miniaturization and High - Density Integration

There is a growing trend towards miniaturization and high - density integration in LED lighting aluminum PCBs. As LED technology continues to evolve, smaller and more powerful LEDs are being developed. To accommodate these advancements, PCBs need to be designed with smaller form factors and higher component densities.

Advanced manufacturing techniques, such as micro - via technology and fine - pitch trace routing, will be used to achieve this. Miniaturized PCBs will not only reduce the size of lighting fixtures but also enable new applications, such as wearable lighting devices and ultra - thin architectural lighting solutions.

Sustainable and Green Manufacturing

Sustainability is becoming an increasingly important aspect of the electronics industry, and LED lighting aluminum PCBs are no exception. Manufacturers are exploring ways to use recycled materials in the production of PCBs, reducing the environmental impact of raw material extraction.

In addition, efforts are being made to develop more energy - efficient manufacturing processes and to minimize waste generation. Green manufacturing practices will not only benefit the environment but also help to reduce production costs, making LED lighting more accessible and affordable.

Advanced Thermal Management Solutions

As the power density of LED lighting systems increases, the demand for more advanced thermal management solutions also grows. Future LED lighting aluminum PCBs may incorporate innovative thermal management techniques, such as the use of phase - change materials (PCM), heat pipes, or liquid cooling systems.

These advanced solutions will be able to handle higher heat loads, ensuring that LEDs can operate at their maximum efficiency even in high - power applications. Improved thermal management will also contribute to the development of more compact and powerful LED lighting systems.

Conclusion

LED lighting aluminum PCBs have become an essential component in modern lighting systems, offering a combination of superior thermal management, electrical reliability, and design flexibility. From commercial and residential lighting to outdoor and automotive applications, these PCBs are driving innovation in the lighting industry.

As technology continues to advance, LED lighting aluminum PCBs will evolve to meet the changing needs of the market. The integration of smart technologies, miniaturization, sustainable manufacturing, and advanced thermal management solutions will shape the future of these PCBs, enabling the creation of more energy - efficient, intelligent, and environmentally friendly lighting systems. For lighting professionals, understanding the capabilities and potential of LED lighting aluminum PCBs is key to staying at the forefront of the industry and delivering cutting - edge lighting solutions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB