-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 13. 2025, 18:56:56

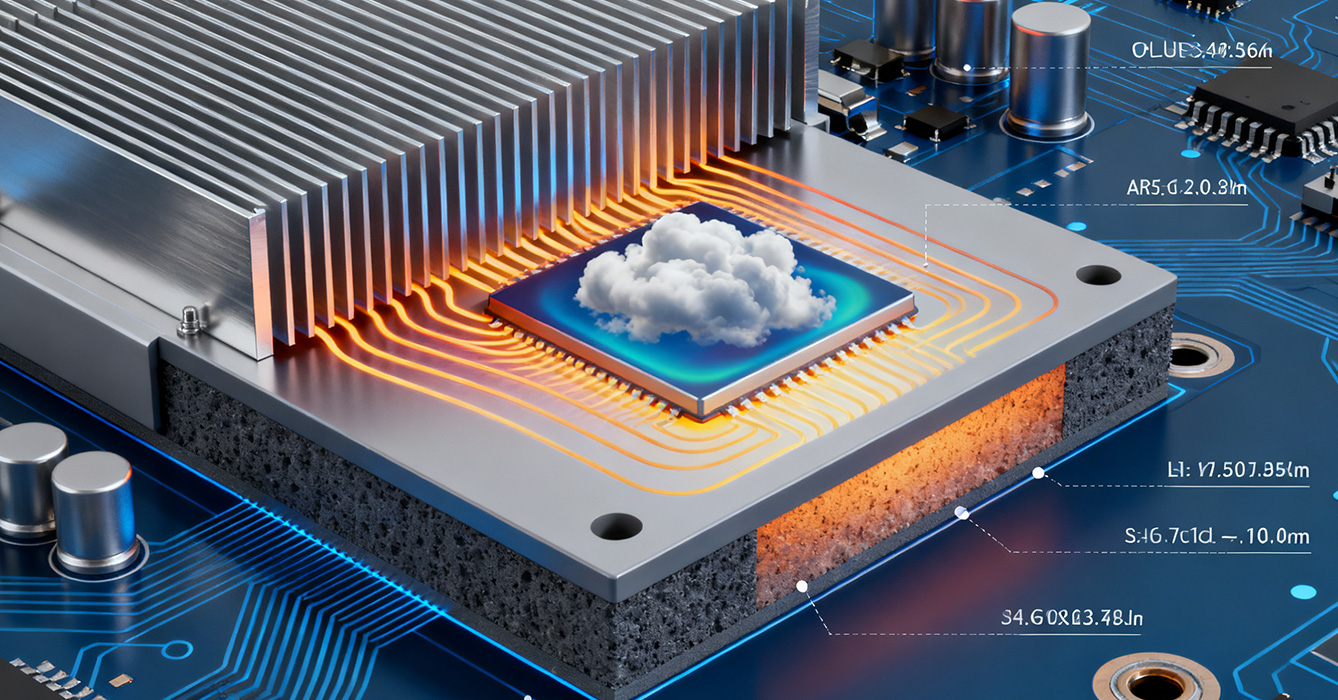

In the world of high-flux lighting—from industrial warehouses to stadiums, automotive headlights to UV sterilization systems—two pain points have long plagued manufacturers and end-users alike: rapid luminous decay and premature failure. High-power LEDs (10W+) deliver brilliant, energy-efficient light, but their concentrated heat often seeps into driver circuits, causing color shift, component burnout, and shortened lifespans. What if there was a technology that kept high-flux lighting bright, stable, and reliable—for years on end?

Enter Thermoelectric Separation Technology—the game-changer that transforms high-power LED lighting from a "high-maintenance investment" to a "long-term value driver." By decoupling LED-generated heat from sensitive electronics (the core of thermoelectric separation), this innovative solution unlocks unprecedented durability and performance, making it the backbone of next-gen lighting systems that demand both power and longevity.

For lighting manufacturers, project engineers, and facility managers, "long-lasting" isn’t just a buzzword—it’s a business imperative. Here’s how this thermoelectric innovation delivers on the promise of enduring high-flux performance:

Traditional high-power LED fixtures lose 30–40% of their brightness within 20,000 hours due to thermal degradation. Thermoelectric Separation Technology eliminates this by routing heat through a dedicated, LED-optimized thermal layer—keeping LED junction temperatures 20–30°C lower. The technology’s signature thermoelectric decoupling ensures heat never invades electrical circuits, preserving component integrity. The result? 50% less light decay over 50,000 hours and a lifespan extended by 30–40%. For industrial high-bay lights or stadium floodlights, this means 5+ years of maintenance-free operation—cutting replacement costs and downtime dramatically.

Color accuracy is make-or-break for applications like retail display lighting, medical examination rooms, and automotive headlights. Thermal-induced color shift (a common flaw in conventional LEDs) is erased by Thermoelectric Separation Technology’s strict isolation of LED chips from driver electronics. With this thermoelectric solution, Δu'v' remains below 0.003—ensuring uniform, true-to-life color from the first hour to the fifty-thousandth. For automotive manufacturers, this means compliance with strict ECE/R112 standards; for retailers, it means products look vibrant and consistent, boosting customer trust.

High-flux lighting often requires dense LED arrays, but crowding chips leads to heat crosstalk in traditional designs. Thermoelectric Separation Technology’s thermal-electrical split lets you pack LEDs 50% denser while keeping temperatures in check. The technology’s ability to separate heat and electricity eliminates the need for bulky heat sinks, resulting in compact, sleek fixtures that deliver 20% higher flux density—perfect for space-constrained applications like architectural lighting, UV curing systems, or smart city street lights. No more sacrificing design for performance.

Driver circuit burnout is the #1 cause of LED fixture failure—directly linked to heat intrusion from LEDs. Thermoelectric Separation Technology’s core advantage (isolating electrical components from thermal loads) reduces component failure rates by 25–30%. Capacitors, resistors, and ICs operate within their optimal temperature range, eliminating premature breakdowns. For municipal street lighting projects or factory floors, this translates to 40% lower maintenance costs and fewer service calls—freeing up resources for other priorities.

Thermoelectric Separation Technology isn’t just a one-size-fits-all solution—it’s tailored to the unique demands of high-growth lighting sectors, leveraging thermoelectric decoupling to solve industry-specific pain points:

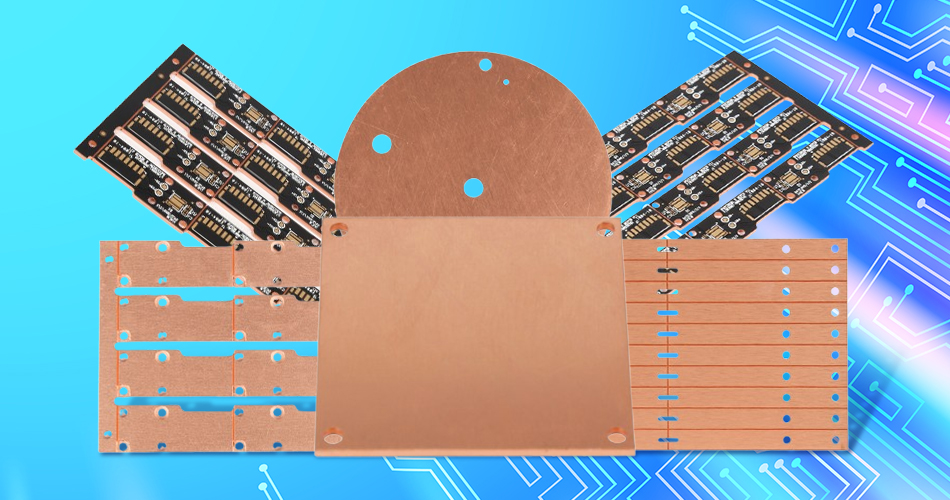

100W+ high-bay fixtures and 500W+ stadium floodlights thrive in harsh, high-temperature environments. This technology’s dedicated copper thermal layer (a cornerstone of thermoelectric separation) dissipates heat from 10–50W LED chips, ensuring consistent performance even in 45°C factory floors or sun-baked stadiums. Imagine a warehouse where lighting lasts 7 years without replacement—this is the reality thermoelectric separation delivers.

Modern cars demand LEDs that withstand -40°C winter nights and 125°C underhood heat. Thermoelectric Separation Technology meets IATF 16949 automotive standards, using its thermoelectric isolation to keep headlights, DRLs, and fog lights bright and color-stable. For EV manufacturers, it also supports compact design—critical for integrating lighting with sleek, aerodynamic vehicle profiles—without compromising thermal resilience.

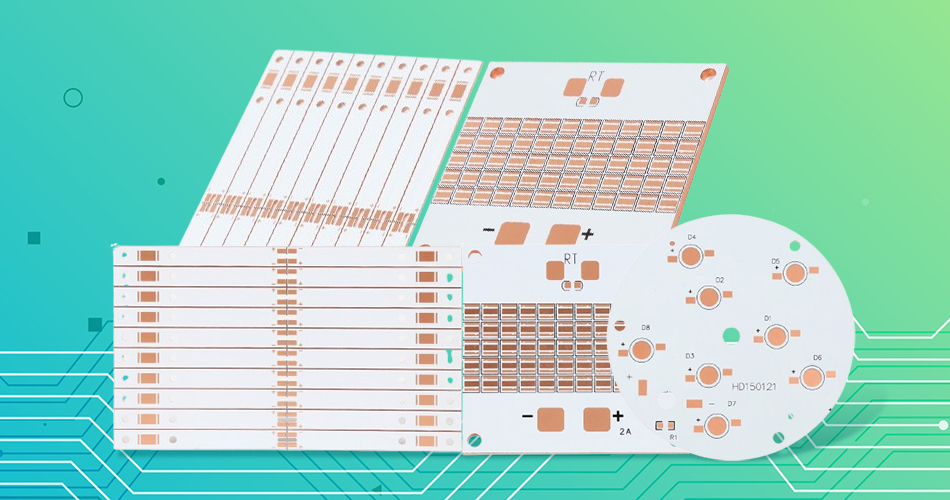

High-power UV-C LED modules (30–100W) for water purification and surface sterilization rely on stable UV intensity. Thermoelectric Separation Technology maintains junction temperatures below 85°C via its dedicated thermal pathway, preserving 254nm UV output and extending module life by 35%. For healthcare facilities and water treatment plants, this means reliable sterilization without frequent module swaps—powered by the technology’s thermoelectric efficiency.

4. Smart City Street Lighting

Municipalities need street lights that last a decade while supporting smart controls (motion sensors, dimming). Thermoelectric Separation Technology’s low failure rate (thanks to thermoelectric decoupling) and compact design make it ideal for smart city deployments—reducing taxpayer costs and enabling energy-efficient, connected lighting networks that stand the test of time.

In a market saturated with "high-power" LED solutions that fall short on longevity, Thermoelectric Separation Technology stands out as a true investment. It’s not just an upgrade to your fixtures—it’s a thermoelectric breakthrough that delivers reliability, performance, and cost savings that resonate with your customers.

Whether you’re a lighting manufacturer looking to differentiate your product line with cutting-edge thermoelectric tech, an engineer designing a mission-critical project, or a facility manager tired of constant maintenance, this technology delivers results that matter.

Contact our team today to:

Get a customized technical assessment of how thermoelectric separation fits your application

Access case studies of successful thermoelectric technology deployments in your industry

Secure exclusive pricing for bulk or project-based partnerships

Don’t settle for lighting that fades fast. With Thermoelectric Separation Technology, build fixtures that illuminate longer, perform stronger, and drive value for years to come—powered by the future of thermal-electrical decoupling.

Thermoelectric Separation Technology—Where High Flux Meets Longevity.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB