-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jan 04. 2026, 16:59:02

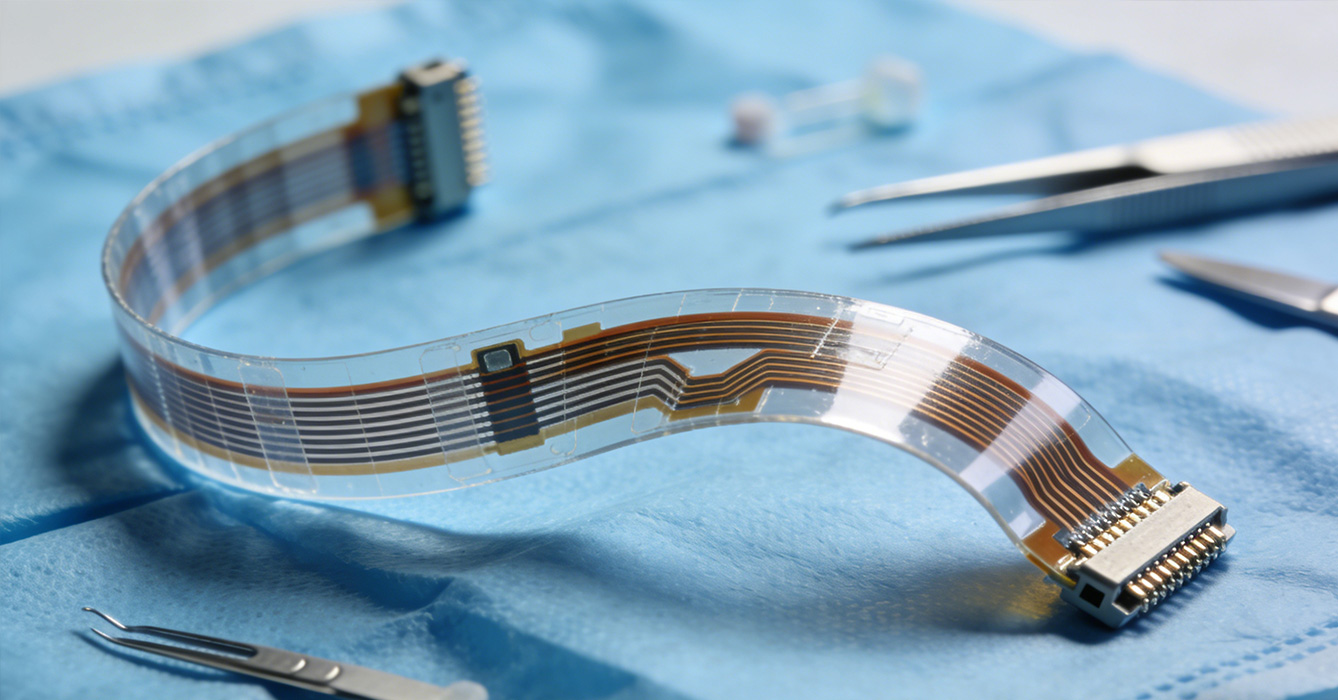

In the rapidly advancing landscape of healthcare technology, the demand for miniaturized, reliable, and biocompatible electronic components has elevated Medical Grade Flexible Circuit Assembly to a pivotal position. Unlike standard flexible circuit assembly, Medical Grade Flexible Circuit Assembly is engineered to meet the most stringent regulatory and performance requirements, as it directly impacts patient safety and treatment outcomes. This specialized assembly process integrates flexible circuit technology with medical-specific design principles, enabling the development of innovative devices ranging from implantable bioelectronics to minimally invasive surgical tools. As healthcare evolves toward personalized and precise medicine, Medical Grade Flexible Circuit Assembly has become an indispensable enabler, ensuring that life-critical devices deliver consistent performance in the complex and sensitive environment of the human body.

The reliability of Medical Grade Flexible Circuit Assembly is built on three medical-specific technical pillars that distinguish it from industrial or consumer-grade alternatives. Firstly, biocompatible material selection is non-negotiable. All components used in the assembly, including substrates, adhesives, and protective coatings, must undergo rigorous biocompatibility testing to ensure they are non-toxic, non-immunogenic, and resistant to bodily fluids and disinfectants. Advanced substrates such as medical-grade polyimide and silk-derived biopolymers are preferred for their ability to integrate with human tissues while maintaining structural and electrical stability.

Secondly, ultra-clean assembly processes are mandatory. Medical Grade Flexible Circuit Assembly must be conducted in controlled clean environments (ISO 8 or higher) to prevent contamination by dust, microbes, or chemical residues—contaminants that could cause adverse reactions in patients. Specialized handling techniques, such as electrostatic discharge (ESD) protection and sterile packaging, are implemented throughout the assembly process to preserve the integrity of the circuit and ensure compliance with medical device regulations.

Thirdly, comprehensive quality control and traceability systems are essential. Compliance with standards such as ISO 13485 (medical device quality management) and IEC 60601 (medical electrical equipment safety) requires full traceability from raw materials to final product. Every step of the assembly process, including component placement, soldering, and testing, is documented in detail. Advanced inspection technologies, such as X-ray imaging and automated optical inspection (AOI), are used to detect minute defects that could compromise device performance, ensuring a near-zero defect rate.

Medical Grade Flexible Circuit Assembly is the backbone of numerous life-saving and life-enhancing medical devices, enabling innovations in diagnosis, treatment, and patient monitoring. In implantable medical devices, such as neurostimulators and cardiac pacemakers, it provides the miniaturization and flexibility needed to fit within the body’s contours. The biocompatible assembly ensures long-term stability, allowing these devices to function reliably for years without causing tissue irritation or rejection.

In minimally invasive surgical tools, such as endoscopic cameras and robotic surgical arms, Medical Grade Flexible Circuit Assembly enables the integration of miniaturized sensors and actuators. These circuits transmit high-resolution images and precise control signals while withstanding the harsh conditions of surgical environments, including exposure to bodily fluids and sterilization processes. This integration enhances surgical precision, reduces patient trauma, and improves recovery outcomes.

Another key application is in wearable and implantable diagnostic devices, such as flexible bioelectronic patches for continuous health monitoring. Medical Grade Flexible Circuit Assembly allows these patches to conform to the skin or internal organs, collecting real-time data on vital signs, glucose levels, or neural activity. The biocompatible design ensures patient comfort and safety, while reliable signal transmission enables accurate diagnosis and personalized treatment plans.

Choosing the right partner for Medical Grade Flexible Circuit Assembly is critical to ensuring regulatory compliance and patient safety. Firstly, evaluate the partner’s regulatory expertise and certification. A qualified partner must hold ISO 13485 certification and have experience navigating the approval processes for medical devices in target markets (e.g., FDA in the US, CE in the EU). Their ability to demonstrate compliance with IEC 60601 and other relevant standards is non-negotiable.

Secondly, assess their expertise in biocompatible materials and cleanroom manufacturing. The partner should have a deep understanding of medical-grade materials and access to controlled洁净 environments. Their ability to implement sterile assembly processes and maintain strict contamination control is essential for producing safe and reliable circuits.

Finally, verify their traceability and quality management systems. A reliable partner should be able to provide full documentation of the assembly process, including material sourcing, production parameters, and testing results. This traceability is critical for post-market surveillance and recall management, ensuring accountability throughout the device’s lifecycle.

As healthcare technology advances, Medical Grade Flexible Circuit Assembly is evolving to meet emerging needs, with two key trends leading the way. The first is the integration of smart functionalities, such as wireless communication and energy harvesting. This enables medical devices to transmit data remotely, supporting telemedicine and real-time patient monitoring. AI-driven quality control during assembly is also enhancing defect detection, further improving reliability.

The second trend is the development of biodegradable assemblies. Researchers and manufacturers are exploring bioresorbable materials that can dissolve naturally in the body after completing their function, eliminating the need for additional surgery to remove implantable devices. These biodegradable circuits maintain the required electrical performance during their operational lifespan while minimizing long-term risks to patients.

In conclusion, Medical Grade Flexible Circuit Assembly is a critical component of modern healthcare technology, ensuring the safety, reliability, and performance of life-critical medical devices. Its focus on biocompatibility, cleanroom manufacturing, and regulatory compliance sets it apart from other types of flexible circuit assembly. By selecting a partner with the right expertise and certifications, medical device manufacturers can leverage this technology to drive innovation in personalized medicine. As smart and biodegradable trends continue to unfold, Medical Grade Flexible Circuit Assembly will play an even more vital role in shaping the future of healthcare, improving patient outcomes and advancing the frontiers of medical science.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB