-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 12. 2025, 15:29:26

In the ever - advancing landscape of modern electronics, where the demand for high - performance, reliable, and compact devices is constantly escalating, Metal - Core Printed Circuit Boards (MCPCBs) have emerged as a revolutionary technology. Unlike traditional printed circuit boards, MCPCBs are engineered with a distinct structure that incorporates a metal core, enabling them to address critical challenges related to thermal management, mechanical stability, and electrical performance. This article comprehensively explores the world of metal - core PCBs, delving into their fundamental characteristics, design principles, manufacturing processes, quality control measures, diverse applications, and the future trends shaping their development.

The Foundation of Metal - Core PCBs

Structure and Composition

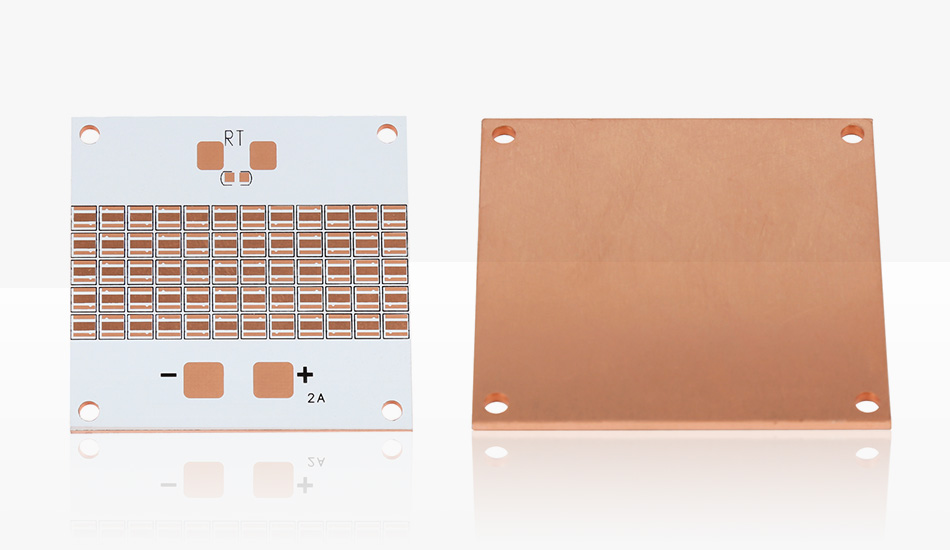

At the heart of MCPCBs lies a three - layer architecture that sets them apart from conventional PCBs. The bottom layer, the metal core, is typically fabricated from materials renowned for their excellent thermal conductivity, such as aluminum or copper. Aluminum, with its favorable cost - to - performance ratio, offers adequate thermal dissipation capabilities along with good mechanical strength, making it a popular choice for a wide range of applications, from LED lighting to consumer electronics. Copper, on the other hand, provides superior thermal conductivity, making it the material of choice for high - end applications where efficient heat transfer is paramount, such as in power electronics for electric vehicles and high - performance computing systems.

Sandwiched between the metal core and the top - most layer is the insulating dielectric layer. This layer serves a dual and critical function. Electrically, it acts as a barrier, isolating the metal core from the conductive traces on the PCB to prevent short - circuits and ensure the integrity of the electrical system. Thermally, it is designed to facilitate the transfer of heat from the components on the PCB to the metal core, acting as a bridge between the two. Composed of materials like thermally conductive epoxy resins, the properties of this layer, including its thickness and thermal conductivity, are carefully optimized during the design phase to strike the perfect balance between electrical insulation and thermal performance.

The top - most layer is the conductive layer, usually made of copper. It features intricately etched electrical traces that form the complex circuitry of the PCB. These traces are responsible for connecting various electronic components, enabling the flow of electrical current. The thickness of the copper layer is tailored to the specific current - carrying requirements of the circuit. In applications with high - current demands, a thicker copper layer is utilized to minimize voltage drops and ensure efficient power transfer, while in lower - current scenarios, a thinner layer suffices.

Advantages Over Traditional PCBs

MCPCBs offer a plethora of advantages that have propelled their widespread adoption in the electronics industry. Their most notable strength lies in their superior thermal performance. In high - power applications, where traditional PCBs often struggle to dissipate heat effectively, leading to component overheating and reduced lifespan, MCPCBs excel. The metal core acts as an efficient heat sink, rapidly drawing heat away from power - hungry components and distributing it across its surface. This efficient heat dissipation not only extends the lifespan of the components but also ensures consistent performance over time, making MCPCBs ideal for applications such as high - brightness LED lighting, where maintaining optimal operating temperatures is crucial for light quality and longevity.

In addition to thermal management, MCPCBs provide enhanced mechanical strength. The metal core adds rigidity to the PCB, making it more resistant to mechanical stress, vibrations, and shocks. This robustness is particularly beneficial in harsh environments, such as automotive engines, industrial machinery, and aerospace systems, where traditional PCBs may succumb to damage under the rigors of operation. The improved mechanical stability of MCPCBs also reduces the risk of component failure due to mechanical forces, enhancing the overall reliability of the electronic device.

Furthermore, MCPCBs can offer improved electrical performance. In some designs, the metal core can be utilized as a ground plane, which helps to reduce electromagnetic interference (EMI). By providing a low - impedance path for electrical currents, the metal core - based ground plane effectively shields the sensitive components on the PCB from external electromagnetic fields, improving signal integrity and the overall electrical performance of the circuit.

Designing Metal - Core PCBs

Thermal Design Considerations

Thermal design is a critical aspect of MCPCB development. The layout of components on the PCB must be carefully planned to ensure efficient heat transfer to the metal core. Components that generate significant amounts of heat, such as power transistors and high - power integrated circuits, should be positioned in close proximity to the metal core and have a direct thermal path through the insulating dielectric layer. This may involve using thermal vias, which are small holes filled with a thermally conductive material, to establish additional routes for heat dissipation.

The choice of materials for the insulating dielectric layer and the metal core also plays a crucial role in thermal design. Materials with high thermal conductivity are preferred for both layers to minimize thermal resistance. Additionally, the thickness of the insulating layer must be optimized. A thinner layer can enhance thermal conductivity but may compromise electrical insulation, while a thicker layer offers better electrical isolation at the expense of reduced thermal performance. Engineers often use thermal simulation tools to model heat flow within the MCPCB and optimize the design for maximum thermal efficiency.

Mechanical Design Aspects

Mechanical design for MCPCBs focuses on ensuring proper mounting and fastening, as well as maintaining the structural integrity of the board. The metal core can be used to provide robust mounting points, and the selection of fasteners is crucial. Factors such as the size, type, and material of the fasteners need to be carefully considered to ensure a secure and stable connection. When designing for mechanical stability, the thickness of the metal core and the overall PCB must be balanced. A thicker metal core can offer greater mechanical strength but may also increase the weight and cost of the PCB. Therefore, engineers must find the optimal thickness that meets the mechanical requirements while adhering to cost and weight constraints.

In addition, the layout of components on the PCB should take into account mechanical considerations. Components that are sensitive to mechanical stress, such as delicate sensors or connectors, should be placed in areas where they are less likely to be affected by vibrations or shocks. The overall shape and size of the PCB also need to be optimized to fit within the constraints of the device enclosure and to ensure proper alignment with other mechanical components.

Electrical Design Principles

Electrical design for MCPCBs involves optimizing the routing of electrical traces to minimize signal interference and voltage drops. The copper layer's thickness and width are carefully designed based on the current - carrying capacity and signal integrity requirements of the circuit. In high - speed applications, where signal integrity is of utmost importance, techniques such as controlled - impedance routing and proper trace termination are employed to prevent signal reflections and crosstalk.

When using the metal core as a ground plane, proper grounding techniques are essential. A well - designed grounding system ensures that electrical currents have a low - impedance path to ground, reducing EMI and improving the overall electrical performance of the circuit. The connection between the conductive layer and the metal core, if used for grounding, must be carefully designed to provide a reliable and low - resistance connection. This may involve using vias or other connection methods to establish a direct electrical link between the two layers.

Manufacturing Metal - Core PCBs

Lamination Process

The lamination process is a key step in the manufacturing of MCPCBs. It involves bonding the metal core, the insulating dielectric layer, and the conductive layer together to form a single, cohesive structure. High - pressure and high - temperature lamination techniques are commonly used to ensure a strong and reliable bond between the layers.

During lamination, precise control of temperature, pressure, and time is essential. The temperature must be high enough to activate the adhesive properties of the insulating dielectric layer and ensure proper bonding, but not so high as to damage the materials. The pressure applied during lamination helps to eliminate air bubbles and ensure a uniform bond across the entire surface of the PCB. The duration of the lamination process is also carefully controlled to allow sufficient time for the layers to bond properly. Specialized laminating equipment and adhesives are used to achieve consistent and high - quality results.

Drilling and Plating

Drilling holes in MCPCBs requires high - precision equipment to ensure accurate hole placement and sizing. Holes are drilled for various purposes, including component mounting, via connections, and electrical routing. High - speed CNC drilling machines are typically used for this task, as they can drill holes with high accuracy and repeatability.

After drilling, the holes are plated with a conductive material, usually copper. The plating process involves electroless copper deposition followed by electroplating to build up the desired thickness of the copper layer. The electroless copper deposition process creates a thin, uniform layer of copper on the non - conductive surfaces of the holes, providing a base for the subsequent electroplating. The electroplating process then increases the thickness of the copper layer to the required specification. Precise control of the plating process is necessary to ensure uniform plating thickness and good adhesion of the copper to the hole walls.

Circuit Pattern Etching

Once the holes are drilled and plated, the circuit pattern is etched onto the copper layer. This is typically done using a photolithography process. A photoresist is first applied to the copper layer, which is then exposed to ultraviolet light through a mask with the desired circuit pattern. The exposed areas of the photoresist are then developed, removing the unwanted photoresist and leaving behind a protective layer on the areas of the copper layer that are to be retained.

The remaining photoresist - protected copper areas are then etched away using a chemical etchant, leaving behind the precisely defined electrical traces. The etching process requires careful control of chemical concentrations, temperature, and etching time to ensure accurate and clean etching of the circuit pattern. After etching, the photoresist is removed, and the PCB is ready for further processing, such as component assembly.

Quality Control in Metal - Core PCB Production

Dimension Inspection

Precision in dimensions is crucial for the proper functioning of MCPCBs. Dimension inspection involves using a variety of tools, such as calipers, micrometers, optical comparators, and 3D coordinate measuring machines (CMMs), to measure the size and location of holes, the thickness of the layers, and the overall dimensions of the PCB. These measurements are compared against the design specifications to ensure that the PCB meets the required tolerance limits. Any deviation from the specified dimensions can affect the fit of components, the performance of electrical connections, and the overall functionality of the PCB, making dimension inspection an essential part of quality control.

Electrical Testing

Electrical testing is performed to ensure the integrity of the electrical circuits on the MCPCB. This includes tests for electrical continuity, which checks that all the electrical traces are connected as intended and there are no open circuits. Insulation resistance testing is also carried out to verify that there is no unwanted electrical conduction between different parts of the PCB, ensuring proper electrical isolation.

In addition, for high - speed and high - frequency applications, signal integrity testing is essential. This involves measuring parameters such as impedance, signal attenuation, and crosstalk to ensure that the electrical signals can be transmitted accurately and without distortion. Any electrical defects detected during testing are carefully analyzed and addressed to ensure the reliability of the MCPCB.

Thermal Performance Testing

Given the importance of thermal management in MCPCBs, thermal performance testing is a critical aspect of quality control. Thermal testing involves measuring the temperature distribution across the PCB under various operating conditions. This can be done using techniques such as infrared thermography, which provides a visual representation of the temperature profile of the PCB.

Thermal resistance testing is also performed to measure the ability of the PCB to conduct heat from the components to the metal core and then to the environment. By comparing the measured thermal performance against the design requirements, engineers can identify any issues with the thermal design or manufacturing process and take corrective actions to ensure that the MCPCB meets the thermal performance specifications.

Applications of Metal - Core PCBs

LED Lighting

The LED lighting industry has been one of the major beneficiaries of MCPCB technology. In high - power LED lighting applications, such as streetlights, stadium lights, and industrial lighting, MCPCBs are widely used. The efficient heat dissipation capabilities of MCPCBs are essential for maintaining the optimal operating temperature of the LEDs. By effectively dissipating the heat generated by the LEDs, MCPCBs prevent light degradation, color shift, and premature failure of the LEDs, ensuring long - term reliability and consistent performance of the lighting fixtures.

In addition to thermal management, the mechanical strength of MCPCBs is also beneficial in LED lighting applications. The ability of MCPCBs to withstand vibrations and shocks makes them suitable for outdoor lighting installations, where they may be exposed to harsh environmental conditions. The compact and lightweight design of MCPCBs also enables more flexible and space - saving lighting designs, contributing to the development of innovative LED lighting products.

Automotive Electronics

Automotive electronics is another key application area for MCPCBs. The harsh operating environment of vehicles, characterized by high temperatures, vibrations, and electrical noise, demands PCBs with excellent thermal, mechanical, and electrical performance. MCPCBs are used in various automotive systems, including engine control units (ECUs), lighting systems, in - vehicle infotainment systems, and advanced driver - assistance systems (ADAS).

In ECUs, MCPCBs are used to manage the complex electrical and electronic functions of the engine, ensuring efficient operation and emissions control. The ability of MCPCBs to dissipate heat effectively is crucial for maintaining the performance of the electronic components in the ECU, which are often located in close proximity to the engine where temperatures can be high. In automotive lighting systems, MCPCBs enable the use of high - power LEDs, providing bright and energy - efficient lighting while ensuring the reliability of the lighting system.

Industrial Electronics

In the industrial sector, MCPCBs are employed in a wide range of applications, including power electronics modules, industrial control panels, and robotic systems. In power electronics, where high - power switching devices generate a significant amount of heat, MCPCBs provide efficient thermal management, allowing for higher power densities and more reliable operation. The enhanced mechanical strength of MCPCBs is also important in industrial applications, as they need to withstand the vibrations and shocks associated with industrial machinery.

In industrial control panels, MCPCBs are used to house the electronic components that control and monitor industrial processes. The ability of MCPCBs to reduce electromagnetic interference is crucial in these applications, as it ensures the accurate operation of the control systems and prevents interference with other electronic devices in the industrial environment. In robotic systems, MCPCBs are used to control the movement and functionality of the robots, providing the necessary electrical and mechanical support for precise and reliable operation.

Aerospace and Defense

The aerospace and defense industries have extremely high requirements for the reliability and performance of electronic components. MCPCBs are used in a variety of aerospace and defense applications, including avionics systems, radar equipment, missile guidance systems, and satellite electronics. The ability of MCPCBs to withstand extreme conditions, such as high - altitude pressures, rapid temperature changes, and intense vibrations, makes them indispensable in these applications.

In avionics systems, MCPCBs are used to control the flight - critical functions of aircraft, ensuring safe and reliable operation. The efficient thermal management provided by MCPCBs is essential for maintaining the performance of the electronic components in the harsh environment of the aircraft. In radar and missile guidance systems, the high - frequency and high - speed electrical performance of MCPCBs, along with their ability to reduce electromagnetic interference, is crucial for accurate detection and guidance.

Challenges and Future Trends

Current Challenges

Despite their many advantages, the production of MCPCBs faces several challenges. One of the main challenges is achieving high precision in manufacturing, especially as electronics continue to miniaturize. Smaller component sizes and tighter tolerances require more advanced manufacturing techniques and equipment. Ensuring consistent quality across a large production volume while keeping costs under control is also a significant challenge. The use of high - quality materials and advanced manufacturing processes can increase the cost of MCPCBs, making it necessary to find ways to optimize the production process and reduce costs without sacrificing performance.

Material compatibility is another issue. The different materials used in MCPCBs, such as the metal core, insulating dielectric layer, and copper conductive layer, may have different thermal expansion coefficients and chemical properties. This can lead to problems such as delamination, warping, and poor electrical connections during the manufacturing process or during operation. Ensuring the compatibility of these materials and developing effective manufacturing processes to address these issues is an ongoing challenge for the industry.

Future Trends

Looking ahead, several trends are expected to shape the future of MCPCBs. Advancements in manufacturing technologies, such as laser - based machining, micro - electro - mechanical systems (MEMS) - based manufacturing, and additive manufacturing, are likely to revolutionize the production of MCPCBs. These technologies offer higher precision, faster processing speeds, and the ability to create complex geometries, enabling the development of smaller, more powerful, and more efficient electronic devices.

Integration with smart manufacturing systems using the Internet of Things (IoT) and artificial intelligence (AI) is also a growing trend. IoT - enabled sensors can monitor various manufacturing parameters in real - time, providing valuable data for process optimization. AI algorithms can analyze this data to predict and prevent quality issues, improve production efficiency, and reduce waste. This integration will lead to more intelligent and automated manufacturing processes for MCPCBs.

There is also a growing emphasis on sustainable manufacturing practices for MCPCBs. As environmental concerns increase, the industry is looking for ways to reduce the environmental impact of PCB production. This includes the use of recycled materials, the development of more environmentally friendly manufacturing processes, and the implementation of energy - efficient technologies. Sustainable manufacturing of MCPCBs will not only help to protect the environment but also reduce costs and improve the long - term viability of the industry.

Conclusion

Metal - Core Printed Circuit Boards have emerged as a game - changing technology in the electronics industry, offering significant advantages in thermal management, mechanical strength, and electrical performance. Their unique structure and design make them well - suited for a wide range of applications, from LED lighting and automotive electronics to industrial and aerospace systems.

While the production of MCPCBs faces challenges in terms of precision manufacturing, cost control, and material compatibility, ongoing technological advancements and emerging trends offer promising solutions for the future. As the electronics industry continues to evolve, MCPCBs will undoubtedly play an increasingly important role in enabling the development of more advanced, reliable, and efficient electronic devices, driving innovation across various sectors and shaping the future of technology.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB