-

- PCB TYPE

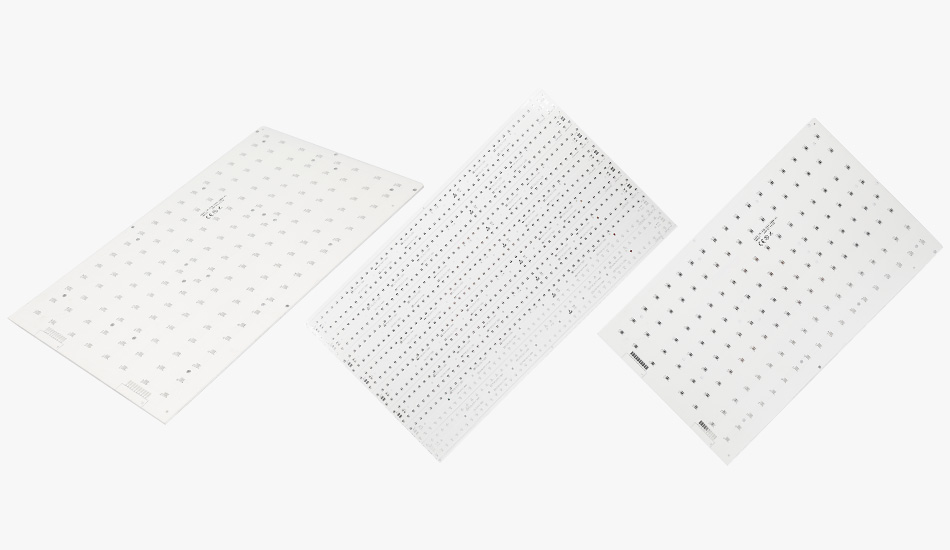

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 11. 2025, 15:17:08

In the fast - paced world of electronics, printed circuit boards (PCBs) are the backbone of modern devices. Among the diverse range of PCBs, metal - core PCBs (MCPCBs) have emerged as a crucial technology, especially in applications where high - power handling and efficient thermal management are essential.

MCPCBs are designed to address the challenges of heat dissipation and mechanical stability that are often encountered in high - performance electronics. Their unique structure, which incorporates a metal core, sets them apart from traditional PCBs and enables them to offer enhanced performance in a variety of applications. This article will explore the key aspects of metal - core PCBs, including their design, manufacturing processes, applications, and future trends.

Structure and Composition of Metal - Core PCBs

The Metal Core

The metal core is the defining feature of MCPCBs. It is typically made from materials such as aluminum or copper, both of which offer excellent thermal conductivity. Aluminum is a popular choice due to its cost - effectiveness and good mechanical properties. It can efficiently dissipate heat generated by high - power components, making it suitable for applications like LED lighting, where cost is a significant factor.

Copper, on the other hand, provides superior thermal conductivity, making it ideal for applications that require extremely high - performance thermal management, such as power electronics in electric vehicles. The metal core acts as a heat sink, drawing heat away from the components mounted on the PCB and distributing it across its surface, thus preventing overheating and ensuring the reliable operation of the electronics.

Insulating Dielectric Layer

Positioned between the metal core and the conductive layer, the insulating dielectric layer plays a dual - role. It electrically isolates the metal core from the conductive traces on the PCB, preventing short - circuits. At the same time, it is designed to have good thermal conductivity to facilitate the transfer of heat from the components to the metal core.

The insulating layer is usually made of thermally conductive epoxy resins. The thickness and material properties of this layer are carefully optimized during the design process. A thinner layer can improve thermal transfer but may compromise electrical insulation, while a thicker layer offers better electrical isolation but could impede heat transfer. Therefore, finding the right balance is crucial to achieve optimal performance.

Conductive Layer

The conductive layer of an MCPCB is the top - most layer, typically made of copper. This layer features precisely etched electrical traces that connect various components on the PCB. The thickness of the copper layer is determined by the current - carrying requirements of the circuit.

In high - current applications, such as power supplies, a thicker copper layer is used to minimize voltage drops and ensure efficient power transfer. The copper layer's conductivity is also crucial for signal integrity in high - speed applications, where fast - switching signals need to be transmitted accurately without distortion.

Advantages of Metal - Core PCBs

Superior Thermal Performance

One of the most significant advantages of MCPCBs is their superior thermal performance. In high - power applications, such as high - brightness LED lighting, the heat generated by the components can quickly lead to performance degradation and reduced lifespan if not properly managed. MCPCBs can dissipate heat up to five times more effectively than traditional FR - 4 PCBs in such applications.

This enhanced thermal performance is due to the direct contact between the components, the insulating layer, and the metal core, which provides a low - resistance path for heat transfer. As a result, the operating temperature of the components is significantly reduced, leading to improved performance and longer - term reliability.

Enhanced Mechanical Strength

The metal core in MCPCBs provides a rigid structure, which greatly enhances the mechanical strength of the PCB. This makes MCPCBs highly resistant to mechanical stress and vibration. In applications such as automotive electronics, where the PCB may be subjected to harsh vibrations and shocks, the mechanical strength of MCPCBs ensures that the components remain securely attached and the PCB does not suffer from mechanical failures.

The metal core also helps to prevent warping of the PCB, which can occur in traditional PCBs under high - temperature or mechanical stress conditions. This is particularly important in applications where the PCB needs to maintain a flat and stable surface for proper component alignment and connection.

Improved Electrical Performance

In addition to thermal and mechanical advantages, MCPCBs offer improved electrical performance. The insulating layer provides excellent electrical isolation between the metal core and the conductive traces, reducing the risk of electrical interference.

In some designs, the metal core can be utilized as a ground plane, which helps to reduce electromagnetic interference (EMI). By providing a low - impedance path for electrical currents, the metal core - based ground plane can effectively shield the sensitive components on the PCB from external electromagnetic fields, improving the overall electrical performance and signal integrity of the circuit.

Design Considerations for Metal - Core PCBs

Thermal Design

Thermal design is a critical aspect of MCPCB design. The layout of components on the PCB should be carefully planned to ensure efficient heat transfer to the metal core. Components that generate a significant amount of heat should be placed in close proximity to the metal core and should have a direct thermal path through the insulating layer.

The thermal conductivity of the insulating layer and the metal core should be considered when choosing materials. Additionally, the use of thermal vias, which are small holes filled with a thermally conductive material, can further enhance heat transfer from the components to the metal core. Thermal vias can be strategically placed around heat - generating components to provide additional paths for heat dissipation.

Mechanical Design

Mechanical design considerations for MCPCBs include ensuring proper mounting and fastening of the PCB. The metal core can be used to provide mounting points for the PCB, and the choice of fasteners should be carefully selected to ensure a secure and stable connection.

When designing for mechanical stability, the thickness of the metal core and the overall PCB should be optimized. A thicker metal core can provide greater mechanical strength but may also increase the weight and cost of the PCB. Therefore, a balance needs to be struck between mechanical requirements and other design constraints.

Electrical Design

In electrical design, the routing of electrical traces on the MCPCB should be optimized to minimize signal interference and voltage drops. The copper layer's thickness and width should be designed based on the current - carrying capacity and signal integrity requirements of the circuit.

When using the metal core as a ground plane, proper grounding techniques should be employed to ensure effective shielding and minimize EMI. The connection between the conductive layer and the metal core, if used for grounding, should be carefully designed to provide a low - impedance path for electrical currents.

Manufacturing Processes for Metal - Core PCBs

Lamination Process

The lamination process is a key step in the manufacturing of MCPCBs. It involves bonding the metal core, the insulating dielectric layer, and the conductive layer together. High - pressure and high - temperature lamination techniques are typically used to ensure a strong and reliable bond between the layers.

During lamination, precise control of temperature, pressure, and time is essential to achieve the desired bond strength and to prevent any delamination or voids between the layers. The use of specialized adhesives and laminating equipment is crucial to ensure the quality of the laminated MCPCB.

Drilling and Plating

Drilling holes in MCPCBs requires high - precision equipment to ensure accurate hole placement and sizing. Holes are drilled for component mounting, vias, and other electrical connections. After drilling, the holes are plated with a conductive material, usually copper, to provide electrical connectivity.

The plating process involves electroless copper deposition followed by electroplating to build up the desired thickness of the copper layer. Precise control of the plating process is necessary to ensure uniform plating thickness and good adhesion of the copper to the hole walls.

Circuit Pattern Etching

Once the holes are drilled and plated, the circuit pattern is etched onto the copper layer. This is typically done using a photolithography process, where a photoresist is applied to the copper layer, exposed to ultraviolet light through a mask with the desired circuit pattern, and then developed to remove the unwanted photoresist.

The remaining photoresist - protected copper areas are then etched away using a chemical etchant, leaving behind the precisely defined electrical traces. The etching process requires careful control of chemical concentrations, temperature, and etching time to ensure accurate and clean etching of the circuit pattern.

Applications of Metal - Core PCBs

LED Lighting

MCPCBs are widely used in LED lighting applications. In high - power LED modules, the metal core effectively dissipates the heat generated by the LEDs, ensuring their long - term reliability and consistent performance. The use of MCPCBs in LED lighting also allows for more compact and efficient designs, as the need for external heat sinks can be reduced.

In decorative lighting applications, the flat and smooth surface of MCPCBs, which can be achieved through proper design and manufacturing, provides an aesthetically pleasing appearance. The ability to mount LEDs directly on the MCPCB also simplifies the assembly process and reduces the overall cost of the lighting fixture.

Automotive Electronics

Automotive electronics is another major application area for MCPCBs. In automotive engines, the high - temperature and high - vibration environment require PCBs with excellent thermal and mechanical performance. MCPCBs are used in engine control units (ECUs), where they handle high - power signals and dissipate the heat generated by the electronic components.

MCPCBs are also used in automotive lighting systems, including headlights and taillights. The reliable performance of MCPCBs in harsh automotive environments ensures the safety and functionality of these critical components.

Industrial Electronics

In industrial electronics, MCPCBs are used in power electronics modules and industrial control panels. In power electronics, where high - power switching devices generate a significant amount of heat, MCPCBs provide efficient thermal management, allowing for higher power densities and more reliable operation.

Industrial control panels often require PCBs with high mechanical strength to withstand the vibrations and shocks present in industrial settings. MCPCBs' enhanced mechanical properties make them well - suited for such applications, ensuring the long - term reliability of the control systems.

Aerospace and Defense

The aerospace and defense industries have stringent requirements for the performance and reliability of electronic components. MCPCBs are used in avionics systems, radar equipment, and missile guidance systems, where they need to operate under extreme conditions, including high - altitude pressures, rapid temperature changes, and intense vibrations.

The superior thermal and mechanical performance of MCPCBs, along with their ability to provide reliable electrical connections, makes them an ideal choice for these high - reliability applications. In aerospace and defense, the failure of an electronic component can have severe consequences, and MCPCBs help to minimize such risks.

Challenges and Future Trends

Current Challenges

One of the current challenges in the development of MCPCBs is the increasing demand for miniaturization. As electronic devices become smaller and more compact, the design and manufacturing of MCPCBs need to adapt to these size constraints. This requires higher precision in manufacturing processes, such as drilling smaller holes and etching finer circuit traces.

Another challenge is balancing the cost - effectiveness of MCPCB production with the need for high - quality components and manufacturing processes. The use of advanced materials and manufacturing techniques can increase the cost of MCPCBs, making it necessary to find ways to optimize the production process without sacrificing performance.

Ensuring material compatibility during processes like plating and lamination is also a challenge. Different materials used in MCPCBs, such as the metal core, insulating layer, and conductive layer, need to work together seamlessly to achieve the desired performance. Any incompatibility between materials can lead to issues such as delamination or poor electrical conductivity.

Future Trends

Advanced manufacturing technologies are expected to play a significant role in the future of MCPCBs. Laser - based machining techniques can offer higher precision in drilling and cutting, allowing for the creation of more complex and miniaturized designs. Micro - electro - mechanical systems (MEMS) - based manufacturing processes may also be used to fabricate MCPCBs with even smaller features and improved performance.

Additive manufacturing, also known as 3D printing, has the potential to revolutionize the production of MCPCBs. It can enable the creation of customized PCB designs with complex internal structures, which may not be possible with traditional manufacturing methods. 3D printing can also reduce waste and production time, making it a more sustainable and efficient manufacturing option.

Integration with smart manufacturing systems using the Internet of Things (IoT) and artificial intelligence (AI) is another future trend. IoT - enabled manufacturing equipment can collect real - time data on the manufacturing process, allowing for better quality control and process optimization. AI algorithms can analyze this data and make predictions to prevent manufacturing defects and improve overall production efficiency.

Sustainable practices will also gain importance in PCB production. As environmental concerns grow, there will be a greater emphasis on reducing waste, using eco - friendly materials, and minimizing the energy consumption associated with PCB manufacturing. This may involve the development of new recycling techniques for MCPCBs and the use of more sustainable materials in their construction.

Conclusion

Metal - core PCBs have become an essential technology in the electronics industry, offering significant advantages in thermal management, mechanical strength, and electrical performance. Their unique structure and design make them well - suited for a wide range of applications, from LED lighting to aerospace and defense.

Despite the challenges they face, such as miniaturization, cost - effectiveness, and material compatibility, ongoing technological advancements offer promising solutions for the future. The development of advanced manufacturing technologies, integration with smart manufacturing systems, and a focus on sustainable practices will continue to drive the evolution of MCPCBs.

As the electronics industry continues to innovate and demand higher - performance, more compact, and more reliable electronic devices, the role of metal - core PCBs will remain crucial. By addressing the current challenges and embracing future trends, MCPCBs will continue to enable the development of cutting - edge electronics and contribute to the advancement of various industries.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB