-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 31. 2025, 16:30:08

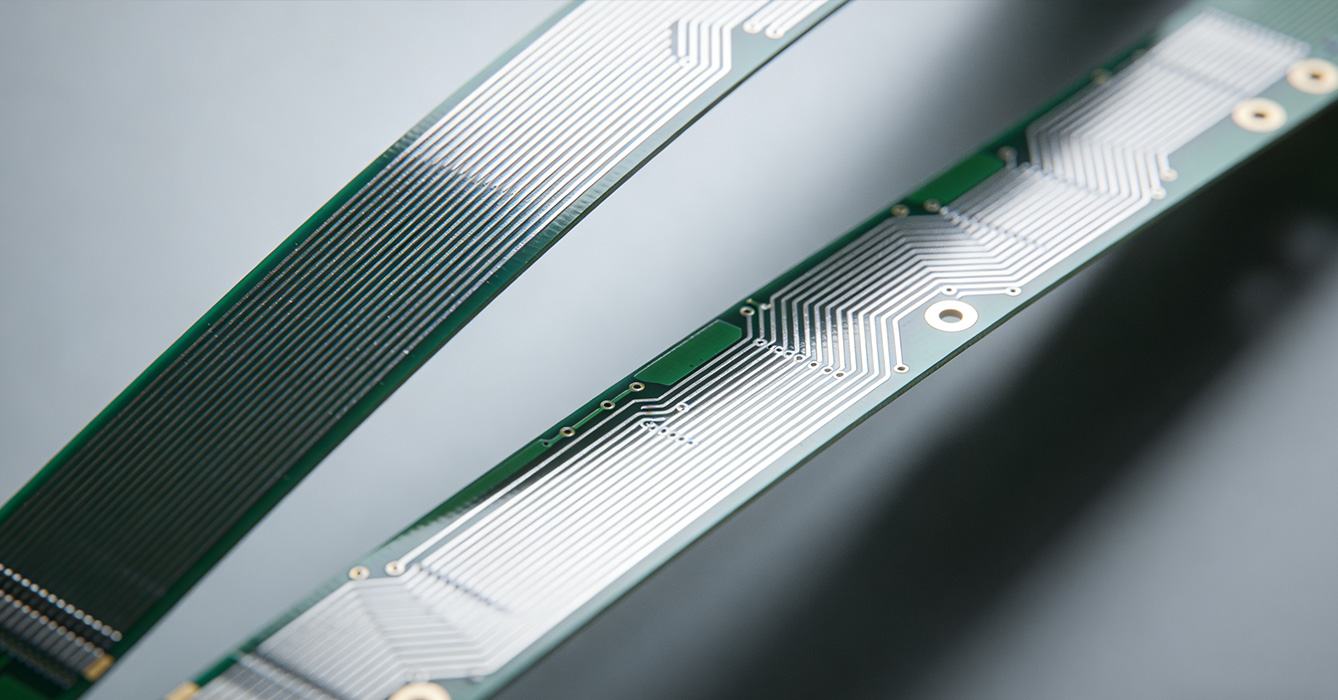

In the highly competitive global electronics market, brand differentiation and product adaptability have become key drivers of success. OEM Custom Flexible Circuit Design emerges as a strategic collaboration model, bridging the gap between electronic brands’ market demands and professional flexible circuit technology. Unlike standard flexible circuit solutions that offer one-size-fits-all options, OEM Custom Flexible Circuit Design provides tailored design services based on brands’ specific product positioning, functional requirements, and market segments. By integrating seamlessly with brands’ R&D and production systems, this design service enables the creation of unique, high-performance electronic products that stand out in the market, making it an indispensable collaborative tool for brands pursuing long-term growth and market leadership.

The unique advantage of OEM Custom Flexible Circuit Design lies in its deep alignment with brand collaboration needs, delivering three core values that standard design services cannot match. Firstly, it realizes brand-specific product customization. Every electronic brand has distinct market positioning—whether it’s high-end consumer electronics emphasizing aesthetics and user experience, industrial equipment focusing on durability and reliability, or medical devices prioritizing safety and biocompatibility. OEM Custom Flexible Circuit Design team works closely with brand R&D teams to translate these positioning requirements into detailed circuit design schemes, ensuring that the flexible circuit not only meets functional needs but also aligns with the brand’s product DNA.

Secondly, it enhances collaborative R&D efficiency. In OEM cooperation, time-to-market and design consistency are critical. Professional OEM Custom Flexible Circuit Design services provide full-process design support, from initial demand communication and scheme formulation to prototype verification and mass production adaptation. By leveraging rich industry experience, designers can proactively identify potential design risks, offer optimized solutions, and ensure that the design scheme is compatible with the brand’s existing production processes. This collaborative model reduces repeated modifications, shortens R&D cycles, and lays a solid foundation for efficient mass production.

Thirdly, it supports supply chain integration and cost optimization. OEM Custom Flexible Circuit Design services not only focus on circuit performance but also consider the practicality of mass production and cost control. Designers optimize material selection and circuit layout based on the brand’s supply chain resources and cost budget, balancing product performance with production costs. Additionally, mature design service providers often have stable upstream material supply chains, which can help brands reduce procurement risks and ensure the stability of mass production supply.

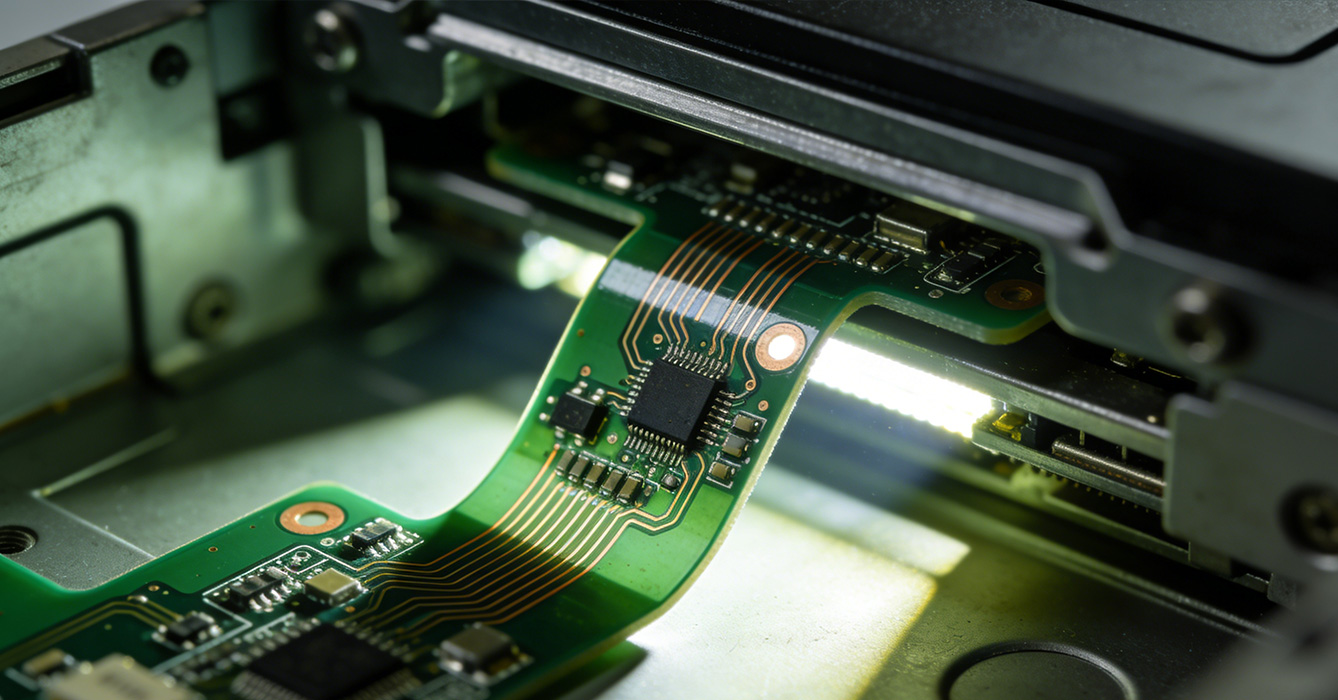

OEM Custom Flexible Circuit Design has been widely applied in various brand collaboration scenarios, driving the innovation and upgrading of electronic products. In the high-end consumer electronics sector, it is a core part of OEM cooperation between brands and flexible circuit designers. For example, in the collaboration of premium smartphone brands and OEM design teams, OEM Custom Flexible Circuit Design is used to develop ultra-thin, high-flexibility circuits for foldable phone hinges. These circuits not only ensure stable signal transmission during repeated folding but also match the brand’s high-end aesthetic and quality requirements, enhancing the product’s market competitiveness.

In the automotive electronics field, OEM Custom Flexible Circuit Design plays a vital role in the collaboration between automotive brands and electronic component suppliers. With the development of intelligent and electric vehicles, automotive brands have increasingly personalized requirements for in-vehicle electronics such as infotainment systems and ADAS (Advanced Driver-Assistance Systems). OEM Custom Flexible Circuit Design team customizes circuits that adapt to the complex spatial layout of vehicle interiors and harsh operating environments, ensuring the reliability and stability of in-vehicle electronic systems. This collaboration helps automotive brands accelerate the launch of intelligent vehicle models and gain an edge in the competitive market.

In the medical device industry, OEM Custom Flexible Circuit Design is indispensable for brand-OEM cooperation. Medical device brands have strict requirements for product safety, biocompatibility, and miniaturization. For example, in the development of portable medical diagnostic equipment, OEM Custom Flexible Circuit Design team customizes ultra-compact, biocompatible flexible circuits that fit the device’s small form factor and ensure accurate signal transmission for diagnostic data. This collaboration ensures that the medical devices meet industry regulatory standards and brand quality requirements, supporting the brand’s expansion in the medical market.

Choosing the right OEM Custom Flexible Circuit Design partner is crucial for the success of brand collaboration. Firstly, evaluate the partner’s design strength and industry experience. Prioritize partners with rich experience in the brand’s target industry, as they can better understand industry regulations, market trends, and product pain points. Reviewing past OEM collaboration cases and brand client testimonials can help verify the partner’s design capabilities and service level.

Secondly, assess the partner’s collaborative R&D capabilities and communication efficiency. In OEM cooperation, smooth communication and efficient collaboration are essential. A reliable design partner should have a professional project team that can maintain close communication with the brand’s R&D team, provide timely design updates, and respond quickly to modification requirements. Additionally, the partner should have mature prototype verification capabilities to ensure that the design scheme is feasible and reliable.

Thirdly, verify the partner’s quality control system and mass production adaptation capabilities. High-quality design is the foundation of product quality, and the partner should have strict quality control standards throughout the design process. At the same time, the design scheme should be compatible with mass production processes to avoid problems such as low production yield rate during mass production. Partners with experience in mass production adaptation can better ensure the smooth transition from prototype to mass production.

As the electronics industry evolves toward digitalization and intelligence, OEM Custom Flexible Circuit Design is also developing in new directions. One key trend is the application of digital collaborative design platforms. By building cloud-based design collaboration systems, brand R&D teams and OEM design teams can achieve real-time data sharing, remote collaboration, and online prototype review. This digital model significantly improves collaboration efficiency, especially for cross-regional OEM cooperation.

Another trend is the integration of intelligent design technologies. With the help of AI (Artificial Intelligence) algorithms, OEM Custom Flexible Circuit Design can realize automated circuit layout optimization, design risk prediction, and performance simulation. This not only improves design accuracy and efficiency but also helps discover potential design problems that are difficult to detect manually. Additionally, the development of sustainable design has become an important focus—OEM Custom Flexible Circuit Design teams are increasingly using eco-friendly materials and energy-efficient design schemes to meet the brand’s sustainable development needs and global environmental protection requirements.

In conclusion, OEM Custom Flexible Circuit Design has become a core driver of brand differentiation in electronic product OEM cooperation. Its ability to align with brand positioning, enhance collaborative efficiency, and support supply chain optimization makes it an indispensable partner for electronic brands pursuing market competitiveness. By selecting a reliable design partner with strong design capabilities, efficient collaboration skills, and strict quality control, brands can fully leverage the value of OEM Custom Flexible Circuit Design to create high-quality, differentiated products. As digitalization and intelligence trends deepen, OEM Custom Flexible Circuit Design will continue to evolve, playing an even more critical role in shaping the future of electronic product collaboration.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB