-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 04. 2025, 11:09:32

Outdoor lighting is an indispensable part of urban and rural landscapes, serving multiple purposes such as enhancing safety, security, and aesthetic appeal. As the demand for energy - efficient and long - lasting lighting solutions has grown, light - emitting diodes (LEDs) have become the preferred choice for outdoor illumination. With this shift, the significance of high - quality printed circuit boards (PCBs) in outdoor lighting systems has also escalated. Outdoor light PCBs are the backbone of these systems, facilitating the electrical connection and management of LED components while withstanding the harsh and unpredictable outdoor environments.

These PCBs face unique challenges, including exposure to moisture, extreme temperatures, dust, UV radiation, and mechanical stress. A well - designed and manufactured outdoor light PCB ensures stable operation of the lighting system, reduces maintenance costs, and extends the overall lifespan of the installation. This article delves into the various elements that contribute to the effectiveness and reliability of outdoor light PCBs.

Material Selection for Outdoor Light PCBs

Substrate Materials

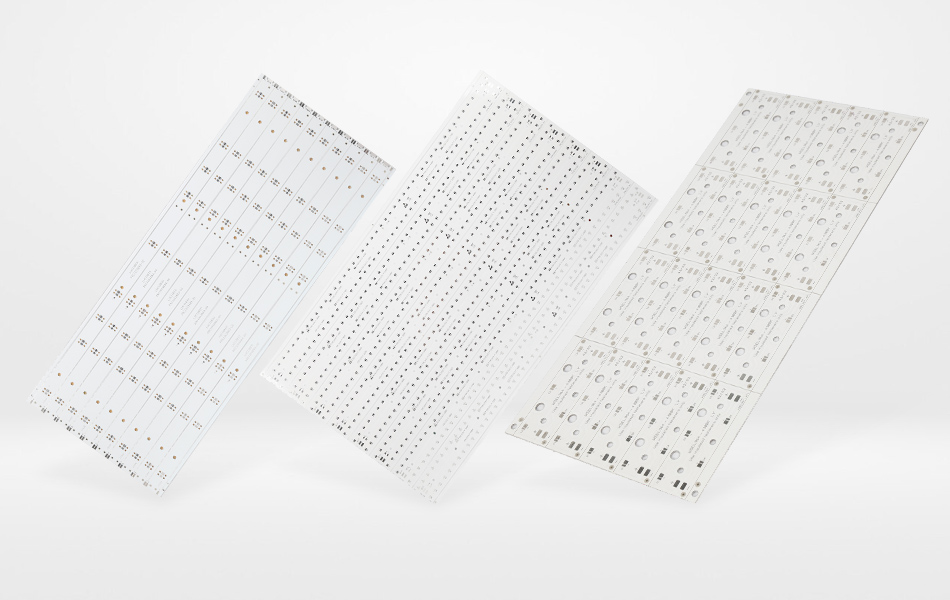

Aluminum Substrates

Aluminum substrates are widely favored in outdoor light PCBs due to their excellent thermal conductivity. In LED lighting, heat dissipation is crucial, as excessive heat can degrade the performance and shorten the lifespan of LEDs. The high thermal conductivity of aluminum allows for efficient transfer of heat away from the LEDs, ensuring they operate within optimal temperature ranges. Additionally, aluminum substrates offer good mechanical strength and are relatively lightweight, making them suitable for a variety of outdoor lighting fixtures. They can also be easily customized in terms of shape and size, enabling flexible PCB designs.

Metal - Core Copper Clad Laminates (MCPCBs)

MCPCBs combine the benefits of a metal core, usually aluminum or copper, with a copper - clad laminate. The metal core provides enhanced thermal performance, while the copper - clad laminate offers excellent electrical conductivity. Copper, in particular, has superior electrical properties compared to aluminum, making MCPCBs an ideal choice for applications that require high - current carrying capabilities. This type of substrate is commonly used in high - power outdoor lighting systems, where efficient heat management and reliable electrical performance are essential.

Ceramic Substrates

For applications demanding the highest levels of durability and performance, ceramic substrates are employed. Ceramic materials possess outstanding thermal conductivity, electrical insulation, and chemical resistance. They can withstand extreme temperature fluctuations without significant degradation, making them suitable for harsh outdoor environments. Additionally, ceramics are highly resistant to UV radiation, which is a major concern for outdoor components. However, ceramic substrates are more expensive and less flexible in terms of manufacturing compared to other materials, which limits their use to specific high - end outdoor lighting applications.

Dielectric Layers

The dielectric layer in an outdoor light PCB serves to insulate the electrical components and facilitate heat transfer. Polyimide is a popular dielectric material due to its excellent thermal stability and electrical insulation properties. It can withstand high temperatures without degrading, ensuring the reliability of the PCB in outdoor conditions. Another commonly used material is ceramic - filled epoxy, which offers enhanced thermal conductivity while maintaining good electrical insulation. This type of dielectric helps in efficiently dissipating the heat generated by the LEDs, improving the overall performance of the lighting system.

Copper Layers

High - purity copper is the standard material for the conductive layers in outdoor light PCBs. Copper's low electrical resistance ensures stable power delivery to the LEDs, minimizing power losses and preventing overheating. The thickness of the copper layer is carefully determined based on the power requirements of the lighting system. Thicker copper layers are used for high - power applications to handle larger currents, while thinner layers may suffice for low - power designs. Surface treatments such as electroless nickel immersion gold (ENIG) or hot air solder leveling (HASL) are often applied to the copper layers to protect them from oxidation and improve solderability.

Protective Coatings

To safeguard the PCB from environmental factors, protective coatings are applied. Conformal coatings are a common choice, providing a thin, protective film over the surface of the PCB. Acrylic conformal coatings offer good moisture resistance and are relatively easy to apply, making them suitable for general outdoor applications. Polyurethane coatings, on the other hand, provide superior abrasion and chemical resistance, making them ideal for more demanding environments where the PCB may be exposed to harsh chemicals or mechanical stress. Silicone conformal coatings are known for their high - temperature resistance and flexibility, allowing them to withstand extreme temperature changes without cracking or peeling.

Design Considerations for Outdoor Light PCBs

Thermal Management Design

Effective thermal management is a top priority in the design of outdoor light PCBs. The layout of the PCB should be optimized to maximize heat dissipation. This includes strategic placement of thermal vias, which are holes that connect the surface copper layers to the substrate, providing a direct path for heat to flow away from the LEDs. The use of large - surface - area pads and traces also helps in spreading the heat and reducing hotspots. Additionally, integrating heat sinks or heat spreaders with the PCB can significantly enhance thermal performance. These components increase the surface area available for heat transfer to the surrounding environment, ensuring that the LEDs operate at lower temperatures.

Electrical Design

The electrical design of outdoor light PCBs must ensure reliable power distribution and signal transmission. Proper trace routing is essential to minimize electrical resistance, electromagnetic interference (EMI), and the risk of short circuits. In multi - LED systems, a well - designed power distribution network is crucial to ensure that each LED receives a consistent and stable supply of power. Impedance control is also important, especially in systems that require high - frequency operation or dimming functionality. By carefully controlling the impedance of the signal traces, designers can prevent signal degradation and ensure the proper functioning of the lighting system.

Mechanical Design

Outdoor light PCBs are exposed to various mechanical stresses, such as vibrations, shocks, and wind loads. Therefore, the mechanical design of the PCB needs to be robust. The choice of substrate material and its thickness can significantly impact the mechanical strength of the PCB. Reinforcement techniques, such as adding stiffeners or using a more rigid substrate, can be employed to enhance the PCB's ability to withstand mechanical stress. The size and shape of the PCB should also be designed to fit snugly within the lighting fixture enclosure, providing adequate support and protection. Additionally, the design should facilitate easy assembly and disassembly for maintenance purposes.

Environmental Sealing and Protection

To protect the PCB from the elements, it is often integrated into a sealed enclosure. The enclosure design should include tight - fitting gaskets and seals to prevent the ingress of water, dust, and other contaminants. The materials used for the enclosure should have high weather resistance, such as UV - stabilized plastics or corrosion - resistant metals. Ventilation holes may be incorporated into the enclosure design, but they must be designed with filters or baffles to prevent the entry of water and debris while allowing for heat dissipation.

Manufacturing Processes for Outdoor Light PCBs

Drilling

The drilling process in PCB manufacturing creates holes for vias, component mounting, and other purposes. Mechanical drilling is a common method for creating larger holes, using rotating drill bits to remove material from the PCB. However, this method may introduce issues such as drill bit wear, burrs, and inaccuracies in hole size. Laser drilling, on the other hand, offers high precision and the ability to create small, complex holes, such as microvias. It uses a laser beam to ablate the material, resulting in clean, accurate holes with minimal burr formation. Laser drilling is particularly suitable for high - density PCB designs.

Plating

The plating process deposits a layer of copper on the drilled holes and the surface of the PCB to ensure electrical conductivity. It typically consists of two stages: electroless plating and electrolytic plating. Electroless plating deposits a thin, uniform layer of copper on non - conductive surfaces, such as the drilled holes, providing a base layer for the subsequent electrolytic plating. Electrolytic plating then builds up the copper layer to the desired thickness by passing an electrical current through the PCB. Advanced plating techniques, such as pulse plating, can be used to improve the quality of the copper layer, reducing voids and enhancing its mechanical properties.

Lamination

Lamination is the process of bonding the different layers of the PCB together, including the substrate, dielectric layers, and copper layers. High - pressure lamination is commonly used for outdoor light PCBs. The layers are stacked together with adhesive films or prepregs between them and then subjected to high pressure and temperature in a laminating press. This process ensures a strong and reliable bond between the layers, maintaining the structural integrity and electrical performance of the PCB.

Component Assembly

After the PCB is fabricated, components such as LEDs, resistors, and capacitors are assembled onto it. Surface - mount technology (SMT) is widely used for its high - density assembly capabilities and efficiency. SMT involves placing the components on the surface of the PCB and soldering them in place using reflow soldering or wave soldering techniques. These methods ensure a secure and reliable connection between the components and the PCB, enabling the proper functioning of the lighting system.

Quality Assurance for Outdoor Light PCBs

Incoming Material Inspection

Before the manufacturing process begins, all incoming materials, including substrates, copper foils, dielectric materials, and components, are thoroughly inspected. Substrates are checked for flatness, thermal conductivity, and mechanical strength. Copper foils are inspected for thickness uniformity and surface quality. Dielectric materials are tested for their electrical insulation properties and thermal stability. Components are verified for their specifications and functionality. Only materials and components that meet the specified quality standards are used in the manufacturing process.

In - Process Quality Control

During the manufacturing process, quality control measures are implemented at various stages. After drilling, the holes are inspected for size accuracy, roundness, and the presence of burrs. In the plating process, the thickness and uniformity of the copper layer are continuously monitored. Lamination is inspected to ensure proper bonding between the layers, and component assembly is checked for correct placement and soldering quality. Automated optical inspection (AOI) and X - ray inspection are often used to detect defects early in the process, allowing for timely corrective actions.

Final Testing

Once the PCB is fully assembled, it undergoes a series of final tests to verify its functionality and reliability. Electrical tests include checking for short circuits, open circuits, and impedance matching to ensure that the PCB can effectively transmit electrical signals and power to the LEDs. Thermal tests are conducted to evaluate the PCB's thermal management capabilities, ensuring that the LEDs operate within their recommended temperature ranges. Environmental tests, such as water ingress tests, dust ingress tests, and temperature - humidity cycling tests, are also performed to ensure that the PCB can withstand the outdoor environment.

Applications of Outdoor Light PCBs

Street and Roadway Lighting

Outdoor light PCBs are extensively used in street and roadway lighting systems. These systems require reliable and efficient PCBs to power the LEDs that illuminate roads, sidewalks, and intersections. The PCBs in streetlights need to be able to withstand various weather conditions, from heavy rain and snow to intense sunlight and high winds. They also need to support features such as dimming and remote control, which are becoming increasingly common in smart street lighting systems.

Parking Lot and Garage Lighting

In parking lots and garages, outdoor light PCBs play a crucial role in providing adequate illumination. These environments are prone to moisture from vehicle exhaust, rainwater runoff, and occasional spills. The PCBs used in parking lot and garage lighting systems must be designed to withstand these conditions and ensure the continuous operation of the lighting. They also contribute to the energy - efficiency of the lighting system, reducing electricity costs for property owners.

Landscape and Garden Lighting

For landscape and garden lighting, outdoor light PCBs enable the creation of beautiful and functional lighting designs. Whether it's highlighting trees, shrubs, or architectural features, or providing ambient lighting for pathways and patios, these PCBs ensure that the LEDs operate reliably. They can be customized to fit the specific requirements of the landscape design, such as size, shape, and lighting intensity.

Building Facade and Architectural Lighting

Building facade and architectural lighting use outdoor light PCBs to enhance the aesthetic appeal of buildings. These PCBs power the LEDs that are used to illuminate the exterior of buildings, creating dramatic lighting effects and highlighting architectural details. They need to be designed to be discreet and blend in with the building's design while providing reliable and energy - efficient lighting.

Emerging Trends in Outdoor Light PCBs

Smart Lighting Integration

The integration of smart technologies into outdoor lighting systems is on the rise. Outdoor light PCBs are being designed to accommodate sensors, wireless communication modules, and control units, enabling features such as remote monitoring, automatic dimming based on ambient light levels, and energy management. This trend is driven by the demand for more efficient, sustainable, and user - friendly lighting solutions.

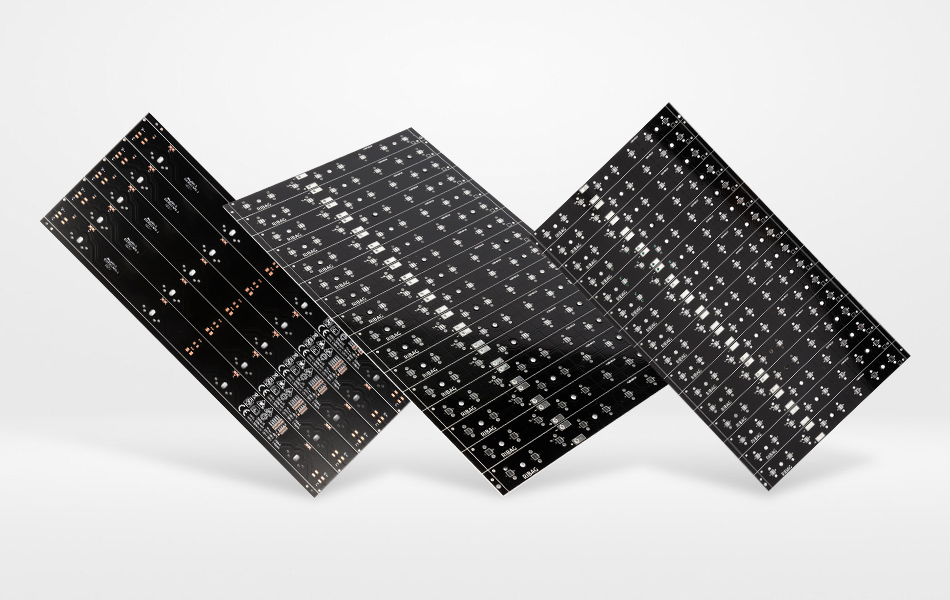

Miniaturization and High - Density Integration

As the demand for smaller and more compact outdoor lighting fixtures grows, there is a trend towards miniaturization and high - density integration in outdoor light PCBs. Manufacturers are developing PCBs with smaller form factors and higher component densities, allowing for more efficient use of space. This requires advanced design and manufacturing techniques to ensure that the PCBs still meet the performance and reliability requirements of outdoor lighting systems.

Sustainable Manufacturing

Sustainability is becoming an increasingly important consideration in the manufacturing of outdoor light PCBs. This includes the use of recycled materials, reducing energy consumption during production, and minimizing waste generation. Manufacturers are also exploring more environmentally friendly manufacturing processes and materials to reduce the environmental impact of outdoor light PCBs.

Conclusion

Outdoor light PCBs are essential components in modern outdoor lighting systems, playing a vital role in ensuring their performance, reliability, and efficiency. From material selection and design to manufacturing and quality assurance, every aspect of outdoor light PCB production is crucial in creating a product that can withstand the harsh outdoor environment. As the outdoor lighting industry continues to evolve, driven by emerging trends such as smart lighting integration, miniaturization, and sustainability, outdoor light PCBs will also need to adapt and innovate. By staying abreast of these developments and understanding the key principles of outdoor light PCB design and manufacturing, professionals, manufacturers, and stakeholders can contribute to the creation of better, more sustainable outdoor lighting solutions.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB