-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 22. 2025, 19:19:55

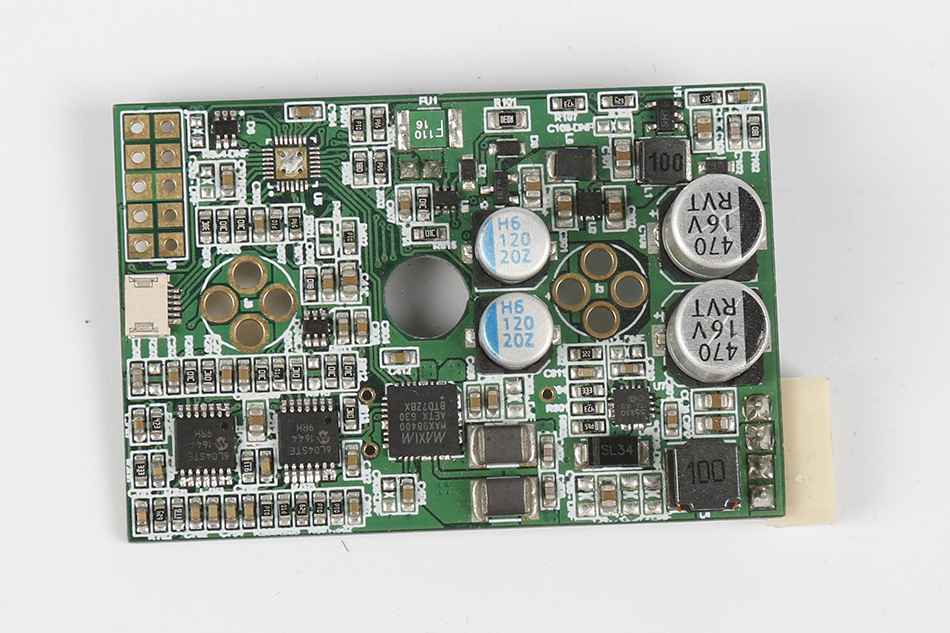

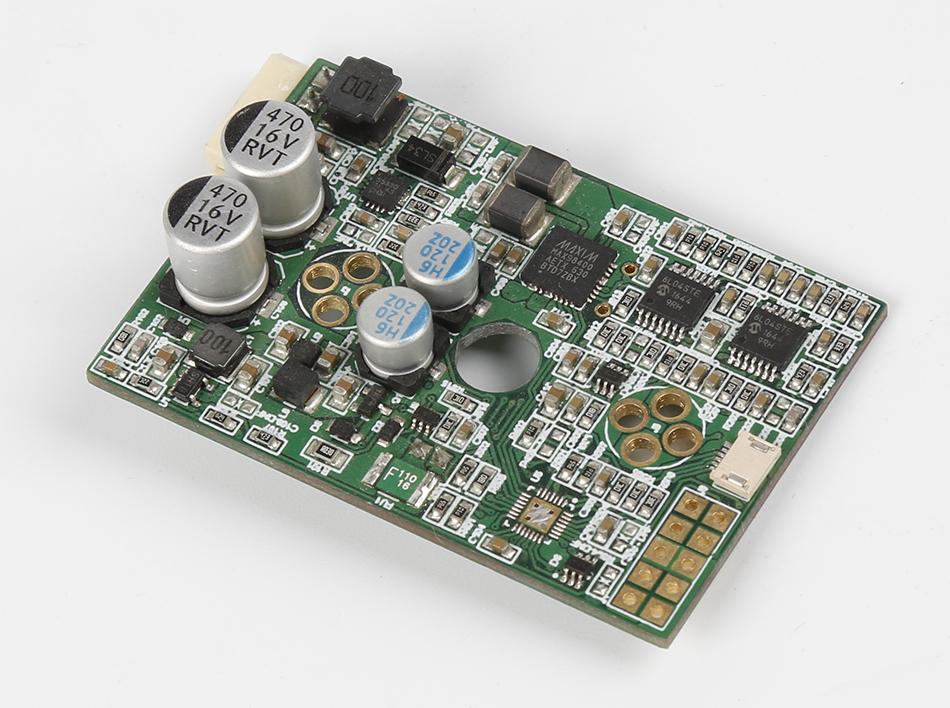

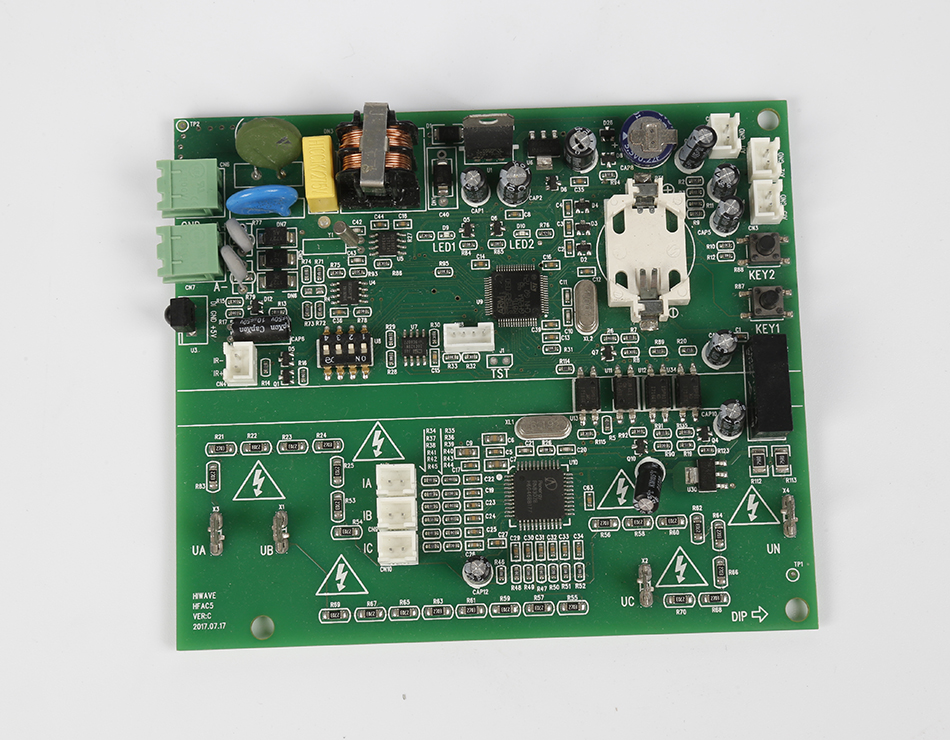

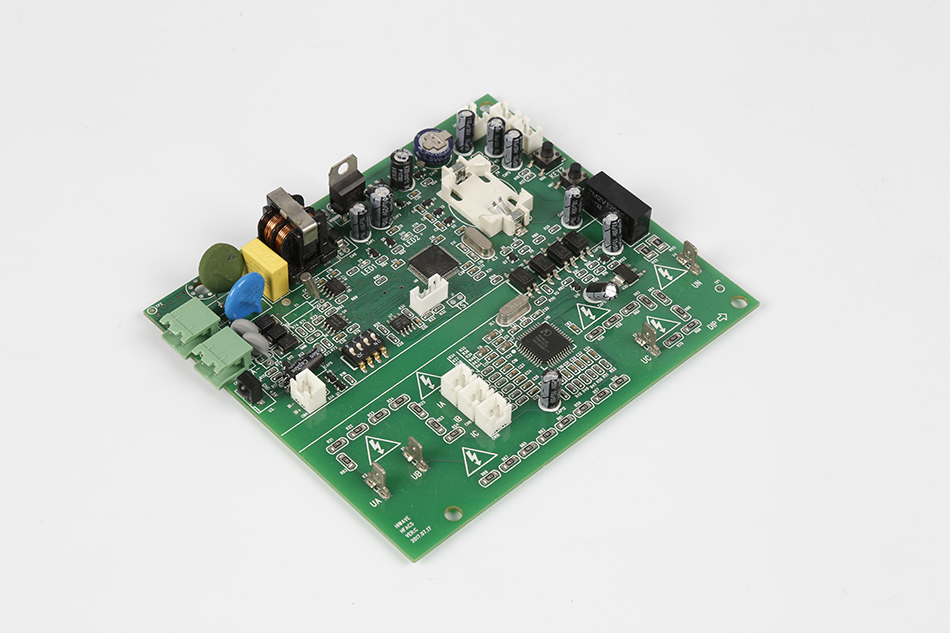

Printed Circuit Boards (PCBs) are at the heart of all electronic devices we use today. From smartphones to kitchen appliances, these tiny components are crucial. But how are they made? Let's explore the PCB assembly process, a key stage in electronics manufacturing that brings designs to life.

PCB assembly refers to the process of mounting various electronic components onto a PCB. This process is distinct from PCB manufacturing, which involves the creation of the board itself. In essence, PCB assembly turns a bare PCB into a functioning circuit.

Before diving into the assembly, it’s essential to understand the role of PCB design. A well-thought-out design is the blueprint of the final product. The design determines the layout of components and the connections between them. This planning stage is crucial for ensuring that the assembly process is efficient and error-free.

The PCB assembly process involves several key steps, each critical to producing a high-quality product. Here is an overview of the main stages:

The first step in PCB assembly is applying solder paste to the board. This paste is a mix of tiny solder balls and flux, and it helps attach components to the board. Using a stencil, the paste is applied only to the areas where components will be placed.

Once the solder paste is in place, the next step is to position the components. This is done by a pick-and-place machine, which precisely places components onto the board. These machines are incredibly fast and accurate, handling thousands of components per hour.

After the components are placed, the board moves into a reflow oven. Here, the solder paste melts and solidifies, creating a strong bond between the components and the board. The reflow process ensures that all connections are secure and reliable.

Once the soldering is complete, the boards undergo a thorough inspection. This can be done manually or with automated optical inspection (AOI) systems. The goal is to detect any defects, such as misplaced components or poor solder joints, before the boards move forward.

Some PCBs require through-hole components, which are inserted manually or by machine. These components have leads that go through holes in the board, providing a strong mechanical bond. Once inserted, they are soldered in place, usually using wave soldering.

The final step in the PCB assembly process is testing. Functional testing ensures that the assembled PCB works as intended. This involves running various tests to check for electrical performance, shorts, and other potential issues. Only boards that pass these tests move on to the next phase of production or shipment.

While the process may seem straightforward, PCB assembly presents several challenges. One of the main issues is the miniaturization of components. As devices become smaller, the components used in them also shrink, making precise placement more challenging.

Another challenge is the complexity of modern PCBs, which can have multiple layers and hundreds of components. Ensuring that every connection is correct and that there are no defects is a meticulous task that requires careful planning and execution.

PCB manufacturing and assembly go hand in hand. The quality of the manufactured PCB directly affects the assembly process. A well-manufactured PCB will have precise dimensions, accurate layer alignment, and reliable surface finishes, all of which contribute to a smoother assembly process.

The PCB assembly industry is constantly evolving with new technologies. Innovations such as surface mount technology (SMT) and advanced pick-and-place machines have significantly increased the speed and accuracy of the assembly process. Additionally, advancements in inspection technology, like AOI and X-ray inspection, have improved quality control measures.

Understanding the PCB assembly process is crucial for anyone involved in electronics manufacturing. From design to testing, each step plays a vital role in ensuring that the final product is of high quality and functions correctly. With ongoing advancements and innovations, the process continues to become more efficient, allowing for the production of increasingly complex and compact electronic devices.

Whether you’re a seasoned engineer or just starting out in the world of electronics, having a solid grasp of PCB assembly will enhance your ability to create reliable and innovative products.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB