-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 04. 2025, 10:56:58

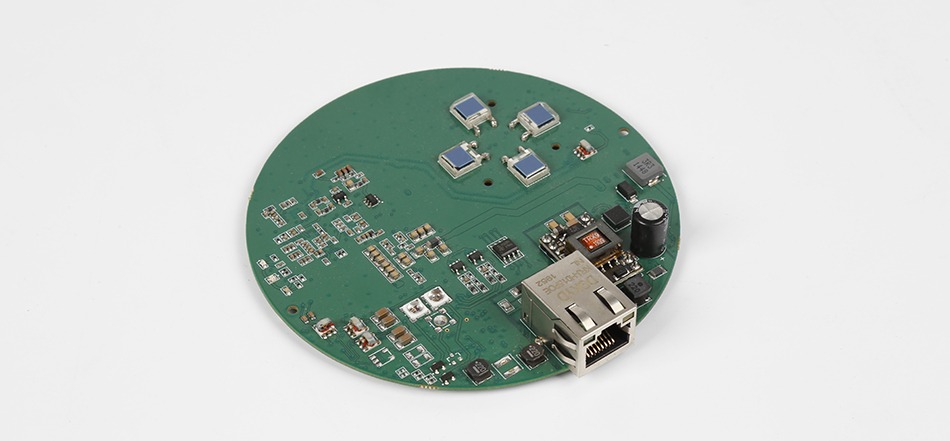

PCB Assembly remains the backbone of modern electronics, transforming bare circuit boards into functional components that power everything from smart appliances to aerospace systems. As technology evolves at an unprecedented pace, PCB assembly has shifted from a purely technical process to a strategic discipline—integrating emerging technologies, prioritizing quality at every stage, and building resilience against global disruptions. Today’s manufacturers must balance precision, speed, and adaptability to meet the demands of sectors like 5G, electric vehicles (EVs), and edge computing. This article explores the latest trends shaping PCB assembly, innovative quality assurance practices, and how the industry is fortifying itself against challenges, ensuring reliable production in a dynamic landscape.

Three key trends are redefining how PCB assembly operates, driving efficiency and enabling new applications:

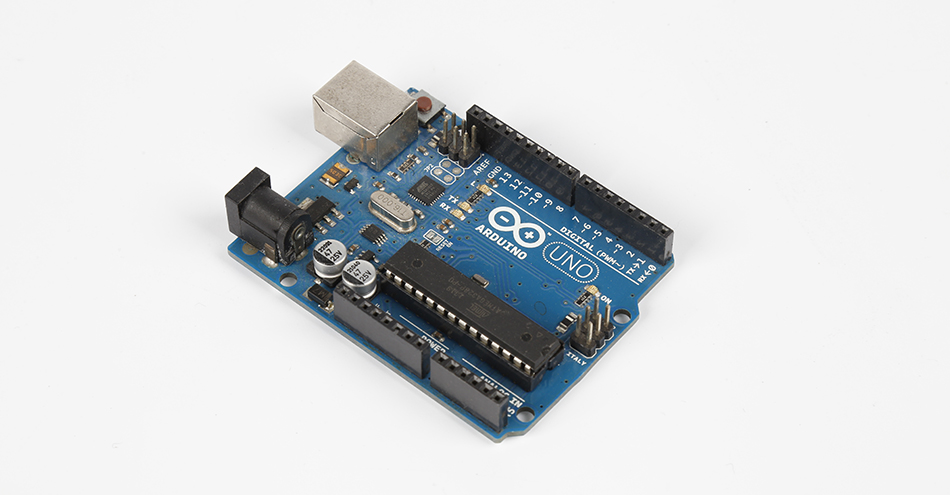

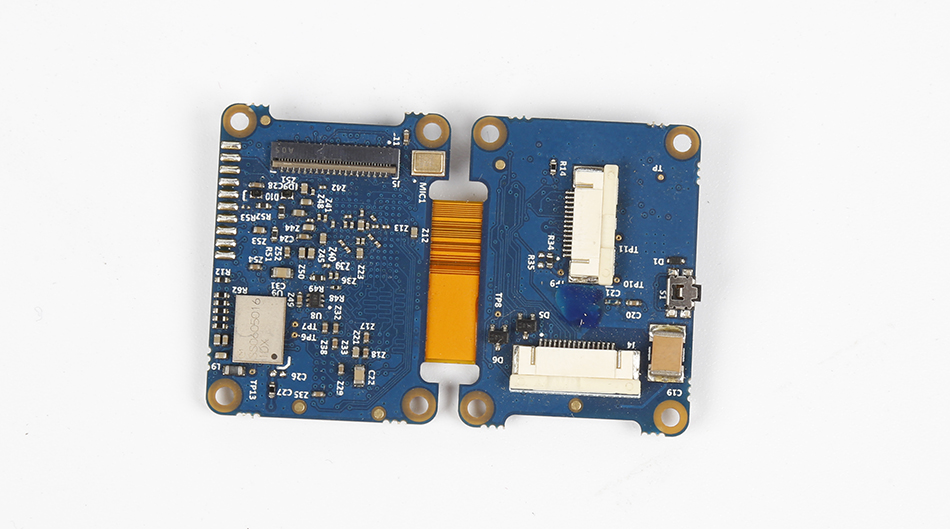

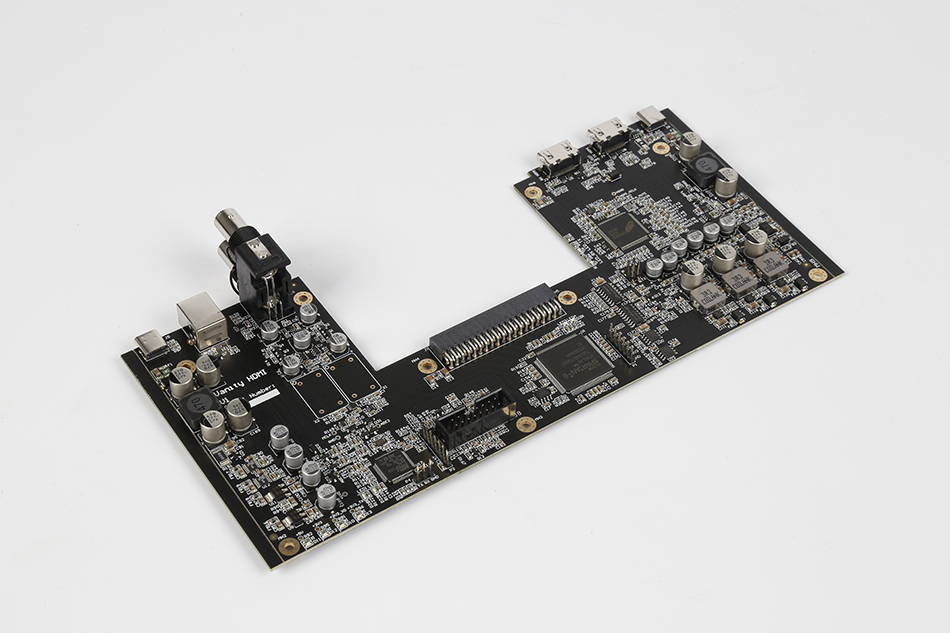

- Miniaturization & High-Density Interconnects: The push for smaller, more powerful devices has accelerated the adoption of ultra-fine-pitch components (e.g., 01005-sized resistors) and HDI (High-Density Interconnect) PCBs. Assembly processes now rely on high-precision pick-and-place machines with sub-micron accuracy and advanced vision systems to handle these tiny components, enabling denser circuitry without sacrificing performance.

- Green Manufacturing & Sustainability: Regulatory pressure and consumer demand for eco-friendly products have made sustainability a priority. PCB assembly lines are transitioning to lead-free solders, water-based fluxes, and energy-efficient reflow ovens. Additionally, closed-loop recycling programs recover precious metals from scrap PCBs, reducing waste and lowering reliance on virgin materials.

- Hybrid & Advanced Packaging Integration: As semiconductors grow more complex, PCB assembly is integrating advanced packaging like Chip-on-Board (CoB), System-in-Package (SiP), and Fan-Out Wafer-Level Packaging (FOWLP). These techniques combine multiple chips into a single assembly, reducing form factor and improving signal integrity—critical for EV powertrains and AI accelerators.

Quality is non-negotiable in PCB assembly, and modern practices go beyond traditional inspection to ensure defect-free production:

Machine learning algorithms power next-generation AOI (Automated Optical Inspection) and X-ray systems. These tools learn from thousands of defect images to identify anomalies like solder bridging, tombstoning, or voids with 99.9% accuracy—far exceeding human capabilities. Real-time analysis lets operators address issues immediately, reducing rework rates by up to 40%.

Blockchain technology is being adopted to create immutable records of every assembly step—from component sourcing to testing. Each PCB gets a unique digital identifier, allowing manufacturers and clients to track its entire lifecycle. This transparency is critical for industries like medical and aerospace, where component provenance and compliance are mandatory.

IoT sensors embedded in assembly equipment monitor parameters like temperature, vibration, and throughput. AI platforms analyze this data to predict when machines will require maintenance, preventing unplanned downtime. For example, a reflow oven’s temperature sensors can alert technicians to calibration issues before they affect solder joint quality.

The PCB assembly industry has learned valuable lessons from supply chain shocks and technical shifts, implementing strategies to stay resilient:

- Diversified Supply Chains: Manufacturers are reducing reliance on single-source component suppliers by partnering with vendors across multiple regions. This mitigates risks from geopolitical tensions or natural disasters that disrupt production in one area.

- Flexible Production Lines: Modular assembly lines with quick-changeover capabilities let manufacturers switch between product types or volumes in hours, not days. This agility is crucial for responding to sudden demand spikes (e.g., for EV components) or shifting market needs.

- Upskilling the Workforce: As technology evolves, training programs focus on equipping workers with skills in advanced machinery operation, and digital tools. Certifications like IPC-A-610 (Acceptability of Electronic Assemblies) ensure a standardized, skilled workforce across the industry.

PCB Assembly is in a period of exciting transformation, driven by miniaturization, sustainability, and digital innovation. By embracing these trends, adopting cutting-edge quality practices, and building resilient operations, manufacturers are well-positioned to meet the demands of next-generation electronics. As devices grow more complex and markets more dynamic, PCB assembly will remain a critical enabler of technological progress—balancing precision, quality, and adaptability to power the innovations of tomorrow. For businesses, partnering with assembly providers that prioritize these elements is key to staying competitive in an ever-evolving industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB