-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 04. 2025, 19:43:23

PCB Solution has evolved beyond mere manufacturing support to become a strategic enabler of electronic innovation, merging design foresight, material science, and adaptive production to address the demands of next-gen technologies. Unlike fragmented service models that silo design, fabrication, and testing, modern PCB solutions unify these stages into a cohesive ecosystem, ensuring that electronic systems not only function but thrive in dynamic environments—from AI-powered industrial robots to energy-efficient smart grids.

In an era where electronics must balance miniaturization, performance, and sustainability, generic PCBs and disjointed processes fall short. A startup developing a quantum sensor, for example, requires more than a circuit board; it needs a partner that understands cryogenic operation constraints and can iterate designs rapidly. Similarly, a utility company deploying smart meters needs PCB solutions that withstand outdoor elements and integrate seamlessly with IoT networks.

This article explores how PCB solutions are adapting to emerging technologies, prioritizing sustainability, and enabling cross-industry innovation. It highlights novel approaches to design collaboration, material innovation, and scalable production—offering insights for engineers and decision-makers seeking to align their electronic systems with future-ready standards.

Modern PCB solutions distinguish themselves through a partnership model, where providers act as extensions of the client’s engineering team, contributing expertise across the product lifecycle. This shift from transactional service to collaborative innovation is reshaping how electronic systems are developed.

Instead of merely executing client blueprints, PCB solution providers now engage in co-design, bringing material and manufacturing insights to early-stage development:

Predictive Design Tools: Leveraging AI-driven simulation platforms, providers model how PCB layouts will perform under real-world stressors—such as thermal gradients in high-power chips or signal degradation in 6G transceivers—before prototyping. This reduces design cycles by up to 40% for complex systems like autonomous vehicle control modules.

Material-Specific Optimization: For flexible electronics (e.g., foldable displays), providers recommend substrate-connector pairings that balance bendability with signal integrity, avoiding costly over-engineering. A recent project for a wearable health monitor saw a 25% reduction in failure rates after co-designers adjusted trace routing to align with polyimide substrate properties.

Regulatory Pre-Compliance: Providers anticipate standards like EU’s upcoming EcoDesign Directive for electronics, integrating recyclable materials and energy-efficient designs from the outset. This proactive approach helped one medical device firm achieve CE marking six months faster than competitors.

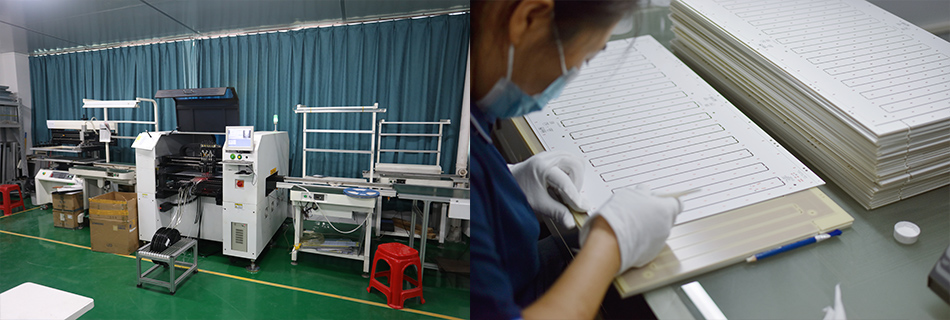

PCB solutions now prioritize flexibility, enabling rapid pivots in production volume and design iterations without sacrificing quality:

Modular Manufacturing Cells: Facilities with reconfigurable lines (e.g., quick-change solder paste printers, adaptive AOI systems) can switch between low-volume, high-complexity boards (e.g., aerospace sensors) and high-volume, standardized ones (e.g., smart home controllers) within hours.

Distributed Production Networks: Partnerships with regional fabrication hubs reduce lead times and carbon footprints. A European IoT firm, for instance, uses a provider with facilities in Germany and Malaysia to serve EU and ASEAN markets, cutting shipping emissions by 30%.

Real-Time Quality Gates: Inline sensors and blockchain-tracked test data ensure every PCB meets specs, with deviations flagged and resolved before reaching assembly. This closed-loop system reduced scrap rates to 0.3% for a client producing industrial motor drives.

As global regulations and consumer demands push electronics toward circularity, PCB solutions are embedding sustainability into every stage—from material selection to end-of-life management.

Providers are replacing traditional materials with eco-friendly alternatives without compromising performance:

Recycled Copper and Fibers: PCB solutions now incorporate up to 30% recycled copper (purified via hydrometallurgical processes) and reclaimed glass fiber in substrates, reducing reliance on virgin mining. Life-cycle assessments show these boards have 22% lower carbon footprints.

Bio-Based Resins: Epoxies derived from plant oils (e.g., linseed, castor) are gaining traction for low-heat applications like consumer electronics, offering comparable dielectric properties to petroleum-based variants while being biodegradable at end-of-life.

PCB solutions optimize production to minimize resource use:

Solar-Powered Fabrication: Facilities with on-site solar arrays and energy storage reduce grid electricity consumption by up to 50%. One provider’s California plant now operates carbon-neutral for 80% of production hours.

Chemical Recycling: Etching waste is processed to recover copper salts and acids, which are reused in production. This closed-loop system cuts hazardous waste by 65% and raw material costs by 18%.

Next-gen technologies demand PCB solutions that push beyond conventional capabilities, addressing unique challenges in extreme environments and advanced functionality.

Quantum processors operate at near-absolute zero (-273°C), requiring PCB solutions that:

Use low-thermal-conductivity substrates (e.g., alumina ceramics) to insulate sensitive qubits from ambient heat.

Integrate superconducting traces (e.g., niobium) that maintain zero resistance at cryogenic temperatures.

Minimize electromagnetic interference through shielded enclosures and grounded via arrays.

PCB solutions for renewable energy systems focus on:

High-voltage isolation (up to 10kV) in solar inverters, using reinforced dielectric layers and creepage-optimized layouts.

Wide-temperature operation (-40°C to 85°C) for wind turbine controllers, with conformal coatings resistant to salt spray and humidity.

Real-time monitoring integration, embedding sensors to track PCB health and predict failures in battery storage systems.

Brain-inspired chips (e.g., Intel’s Loihi) require PCB solutions that:

Support ultra-dense interconnects (10,000+ traces per square inch) to mimic neural networks.

Manage heat in 3D-stacked architectures via microfluidic cooling channels integrated into the PCB substrate.

Reduce signal latency through optimized trace lengths and low-loss dielectrics.

Choosing a provider now requires evaluating not just current capabilities but future readiness. Key criteria include:

Look for providers investing in R&D for next-gen technologies—e.g., 3D-printed PCBs, graphene-based traces, or AI-driven design automation. Partnerships with universities or tech consortia (e.g., IEEE’s PCB standards group) indicate a commitment to innovation.

Prioritize providers with ISO 14064 (carbon accounting) and IPC 1752 (material declaration) certifications, demonstrating transparency in environmental claims. Ask for life-cycle assessments of their solutions to verify sustainability metrics.

Providers with experience across sectors (aerospace, medical, consumer) bring transferable insights—e.g., applying automotive-grade vibration testing to industrial IoT PCBs. This breadth reduces risk when scaling into new markets.

Prefer providers with cloud-based collaboration platforms that share real-time data on design progress, production metrics, and quality reports. This visibility enables agile decision-making and faster issue resolution.

PCB Solution has transcended its traditional role to become a cornerstone of technological innovation, enabling the electronics of tomorrow through integration, sustainability, and adaptability. By fostering collaborative design, prioritizing green practices, and embracing emerging tech challenges, modern PCB solutions are not just supporting progress—they are driving it.

For engineers and organizations aiming to stay competitive, partnering with a forward-thinking PCB solution provider is essential. These partnerships unlock the ability to iterate faster, reduce environmental impact, and tackle the most demanding technical challenges—ultimately turning ambitious electronic concepts into tangible, impactful products. As technology continues to evolve, the PCB solution will remain a critical catalyst, bridging design vision with real-world performance.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB