-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 22. 2025, 15:46:56

As automobiles evolve from mechanical machines to sophisticated electronic platforms, PCB for automotive applications has become a cornerstone of vehicle innovation. Modern vehicles integrate hundreds of electronic components—from advanced driver-assistance systems (ADAS) and infotainment to electric powertrains and battery management—all relying on PCBs to deliver reliable performance in harsh operating environments. Unlike consumer electronics PCBs, automotive-grade PCBs must withstand extreme temperatures, constant vibration, chemical exposure, and decades of rigorous use. This article explores the unique role of automotive PCBs, their design requirements, application across vehicle systems, and the trends shaping their evolution in the era of electrification and autonomy.

The Critical Role of PCBs in Automotive Electronics

Automotive PCBs serve as the nervous system of vehicles, connecting sensors, processors, actuators, and power sources to enable seamless functionality. Their importance spans three core areas:

Reliability in Extreme Environments

Vehicles operate in environments far more demanding than consumer devices:

Temperature Extremes: PCBs in engine bays endure high heat (up to 150°C), while those in exterior sensors face sub-zero cold (-40°C). Automotive PCBs are engineered to resist thermal expansion mismatches that cause delamination or solder joint failure.

Mechanical Stress: Constant vibration from roads, engine operation, and vehicle movement requires PCBs with robust substrates and reinforced solder joints to prevent cracking or component detachment.

Chemical and Environmental Exposure: PCBs must resist corrosion from moisture, road salts, oils, and fuels—particularly critical for underhood components or exterior sensors.

Enabling Advanced Vehicle Systems

Automotive PCBs are integral to transformative technologies:

Electrification: In electric vehicles (EVs) and hybrids, PCBs manage power flow in batteries, inverters, and chargers, ensuring efficient energy conversion and thermal safety.

Autonomy: ADAS and autonomous driving systems depend on PCBs to process data from radar, LiDAR, and cameras, enabling real-time decision-making for collision avoidance and navigation.

Connectivity: Vehicle-to-everything (V2X) communication, infotainment, and telematics rely on PCBs to support high-speed data transmission with minimal signal loss.

Design Standards and Requirements for Automotive PCBs

Automotive PCBs adhere to stringent standards to meet safety, performance, and regulatory demands:

Industry Standards and Certifications

IATF 16949: The global quality management standard for automotive production, ensuring PCB manufacturing processes are consistent, traceable, and focused on defect prevention.

ISO 26262: Addresses functional safety in road vehicles, with PCBs in safety-critical systems (e.g., braking, steering) meeting risk classification requirements (ASIL A-D).

UL 94 and IPC Standards: Flammability ratings (UL 94 V-0) and IPC-6012 specifications ensure PCBs meet mechanical, electrical, and thermal performance benchmarks.

Material Selection for Automotive PCBs

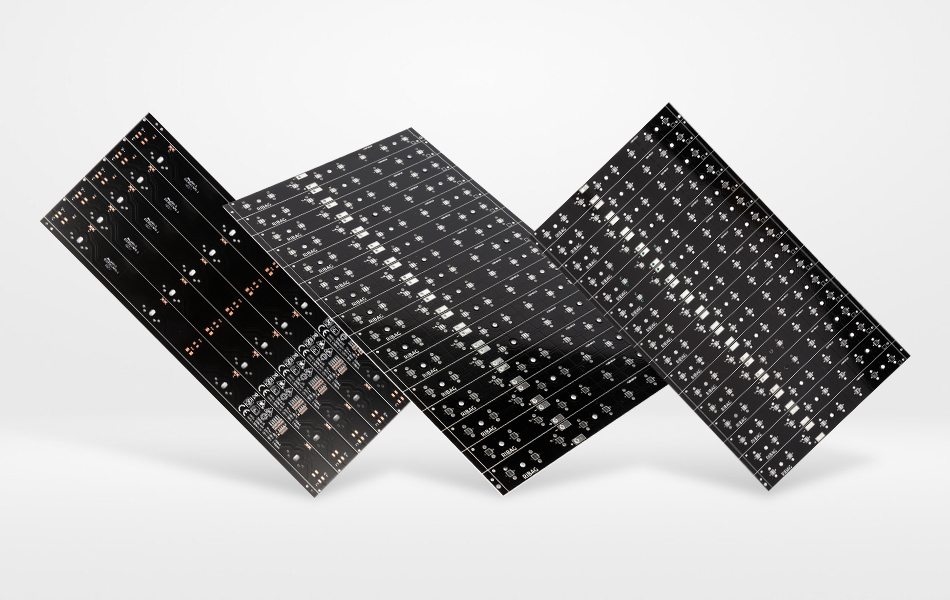

Substrates: Aluminum, ceramic, and high-temperature FR-4 variants are chosen based on application needs. Aluminum substrates excel in thermal management for power-dense components, while ceramic substrates offer stability in high-frequency ADAS systems.

Dielectrics: Thermally conductive, halogen-free dielectrics (e.g., ceramic-reinforced epoxies) balance electrical insulation with heat transfer, critical for EV inverters and LED drivers.

Copper and Conductors: High-purity copper with uniform thickness ensures low resistance and efficient heat spreading, with finishes like electroless nickel immersion gold (ENIG) enhancing solderability and corrosion resistance.

Design Considerations for Performance

Thermal Management: PCB layouts optimize heat dissipation through large copper planes, thermal vias, and direct bonding to heat sinks. This prevents overheating in power semiconductors and sensors.

Signal Integrity: High-frequency PCBs (e.g., for 5G and radar) use controlled impedance traces, shielding, and low-loss dielectrics to minimize signal distortion, ensuring accurate data transmission in ADAS and connectivity systems.

Miniaturization and Density: High-density interconnect (HDI) PCBs with micro-vias and fine-pitch components enable compact designs, critical for fitting electronics in space-constrained vehicle compartments.

Applications of PCBs Across Vehicle Systems

Automotive PCBs support diverse functions, from safety-critical to comfort-focused systems:

Power and Energy Management

Battery Management Systems (BMS): PCBs monitor cell voltage, temperature, and state of charge (SOC) in EV batteries, balancing cells to prevent overcharging and extend lifespan. Thermal management features prevent hotspots that could lead to thermal runaway.

Inverters and Motor Controls: Convert DC battery power to AC for electric motors, with PCBs managing high currents and voltages while dissipating heat to maintain efficiency.

Onboard Chargers (OBCs): Regulate AC-to-DC power conversion during charging, with PCBs ensuring safe, fast charging even in extreme ambient temperatures.

Safety and Autonomy Systems

ADAS Sensors: PCBs in radar (24GHz, 77GHz), LiDAR, and cameras process raw data into actionable insights, with shielding to reduce electromagnetic interference (EMI) from other vehicle systems.

Electronic Control Units (ECUs): Centralized and domain controllers use PCBs to coordinate functions like engine management, braking, and stability control, ensuring real-time responsiveness.

Passive Safety: Airbag deployment systems rely on PCBs to trigger inflators based on crash sensor data, with redundant designs to prevent failures.

Comfort, Connectivity, and Lighting

Infotainment and Telematics: PCBs power touchscreens, navigation, and connectivity modules, supporting high-resolution displays and wireless communication (Wi-Fi, Bluetooth, 5G).

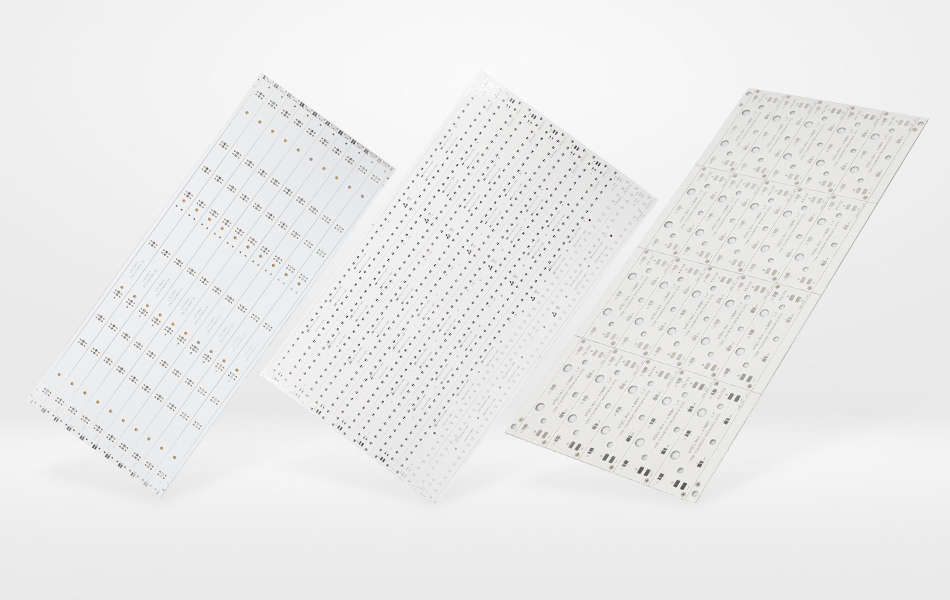

Lighting Systems: LED headlights, taillights, and interior lighting use PCBs to manage power and dimming, with high-reflective solder masks enhancing light efficiency and thermal management preventing LED degradation.

Climate Control: PCBs regulate HVAC systems, ensuring precise temperature control and energy efficiency in cabin environments.

Manufacturing and Testing of Automotive PCBs

Producing automotive PCBs requires precision manufacturing and rigorous testing to ensure reliability:

Advanced Manufacturing Processes

Lamination: Substrates, dielectrics, and copper layers are bonded under controlled temperature and pressure to ensure uniform adhesion, minimizing thermal resistance and delamination risk.

High-Precision Etching: Laser or chemical etching creates fine circuit traces and micro-vias, enabling high-density designs for ADAS and ECUs with tight component spacing.

Solder Mask and Finishing: Automotive-grade solder masks (e.g., high-temperature, UV-resistant variants) protect copper traces, with finishes applied to enhance solderability and corrosion resistance.

Testing and Validation Protocols

Electrical Testing: Continuity checks, insulation resistance, and high-potential (hipot) tests verify electrical performance, ensuring no short circuits or leakage.

Environmental Stress Testing: PCBs undergo thermal cycling, vibration testing, humidity exposure, and chemical resistance tests to simulate real-world conditions and validate durability.

Reliability Testing: Long-term endurance tests (e.g., accelerated aging) predict lifespan and performance degradation, ensuring PCBs meet vehicle service life expectations (10+ years).

Trends Shaping the Future of Automotive PCBs

Electrification and High-Voltage Systems

As EV adoption grows, automotive PCBs are evolving to support:

High-Voltage Architectures: 800V systems require PCBs with enhanced insulation, thicker dielectrics, and robust shielding to manage increased power levels safely.

Integrated Power Modules: PCBs are integrating with power semiconductors (e.g., SiC, GaN) in modular designs, reducing size and improving thermal efficiency in inverters and chargers.

Autonomy and Sensor Integration

Sensor Fusion PCBs: Multi-functional PCBs combining radar, LiDAR, and camera interfaces are emerging, reducing complexity and improving data processing speed for autonomous systems.

High-Frequency Optimization: PCBs for 77/81GHz radar and next-gen LiDAR require low-loss materials and precise trace geometries to minimize signal attenuation, critical for long-range object detection.

Sustainability and Circular Design

Eco-Friendly Materials: Manufacturers are adopting recycled substrates, halogen-free dielectrics, and lead-free solders to align with automotive OEMs’ carbon-neutral goals.

Design for Recycling: PCBs are being engineered for easier disassembly and material recovery at end-of-life, supporting circular economy initiatives in automotive manufacturing.

Conclusion

PCB for automotive applications is a linchpin of modern vehicle innovation, enabling electrification, autonomy, and connectivity while ensuring safety and reliability in harsh environments. By adhering to stringent standards, leveraging advanced materials, and embracing precision manufacturing, automotive PCBs meet the unique demands of vehicle systems—from underhood power modules to cabin infotainment. As the automotive industry continues to evolve, PCBs will play an increasingly vital role in driving efficiency, safety, and sustainability, cementing their status as a critical technology in the future of mobility.

Keywords: PCB for automotive, automotive electronics, automotive PCBs, ADAS PCBs, EV PCBs, IATF 16949 PCB, automotive PCB design, automotive reliability.

This article provides a comprehensive overview of automotive PCBs, emphasizing technical depth, industry relevance, and SEO optimization to support search engine visibility. By focusing on applications, standards, and trends, it offers valuable insights for engineers, manufacturers, and stakeholders in the automotive electronics ecosystem.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB