-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 30. 2025, 18:56:53

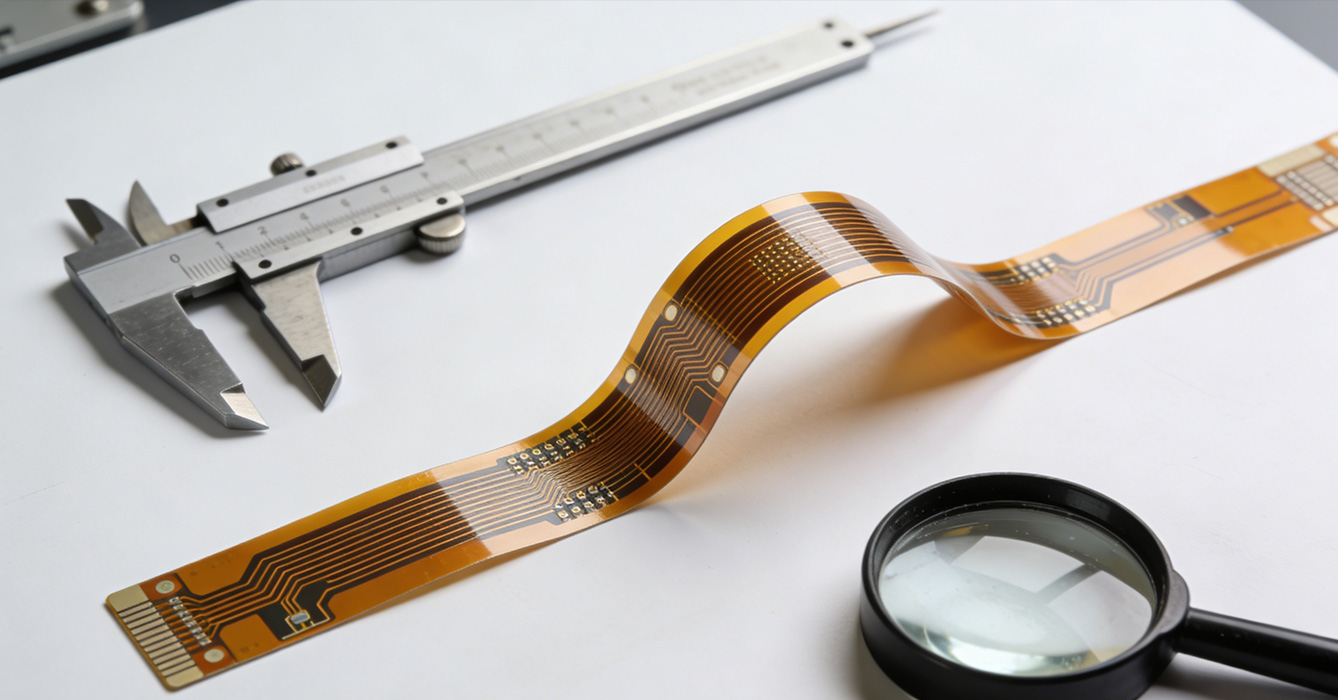

In the era of high-end electronics pursuing extreme performance and environmental adaptability, Polyimide Customize FPCB Solution has emerged as a core enabler for technological innovation. Polyimide, known as the "golden film" in the electronic material field, boasts exceptional thermal stability, electrical insulation, and environmental resistance. Combined with customized flexible printed circuit board (FPCB) design, this solution effectively addresses the pain points of traditional FPCB materials that struggle to withstand harsh conditions such as high temperatures, strong radiation, and chemical corrosion. From aerospace equipment operating in extreme cosmic environments to precision medical devices requiring long-term stable operation, Polyimide Customize FPCB Solution provides tailored, high-reliability circuit solutions, becoming an indispensable cornerstone for high-end electronic products.

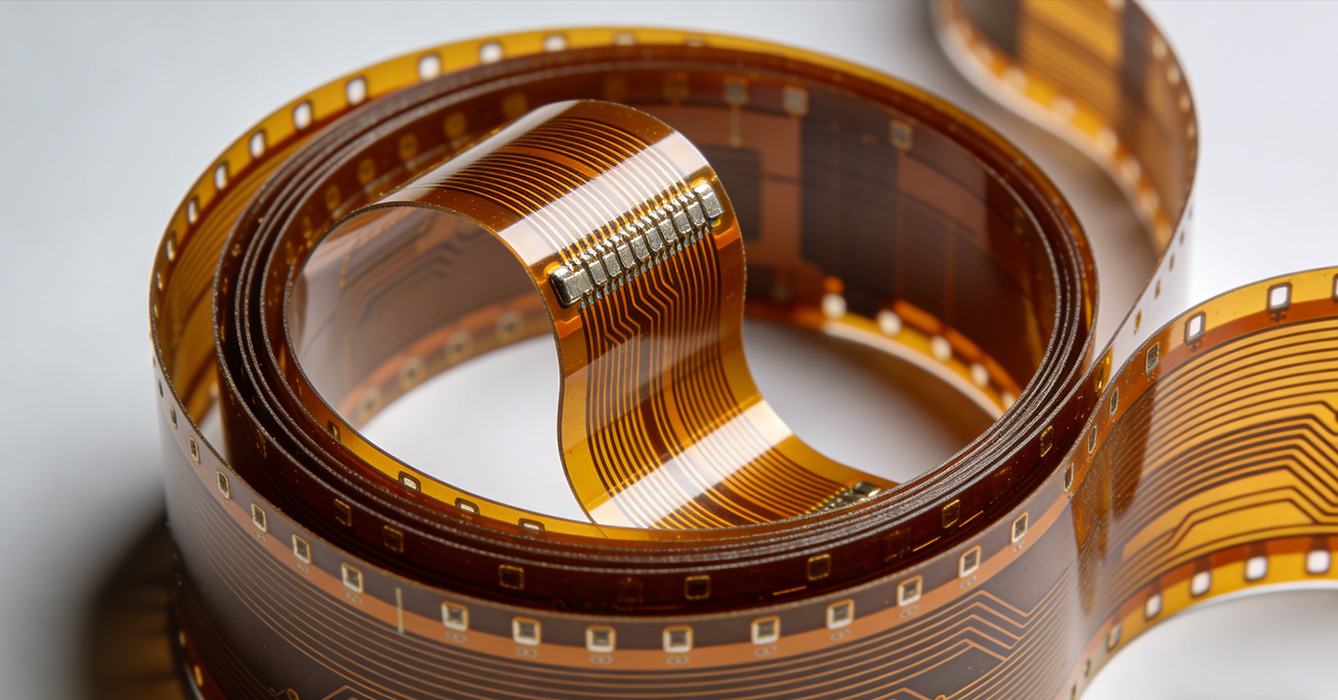

The unique value of Polyimide Customize FPCB Solution lies in the synergistic effect of polyimide material properties and personalized design. Firstly, it possesses outstanding extreme environment adaptability. Polyimide can maintain stable physical and chemical properties in a wide temperature range from -269℃ to 280℃, and can withstand short-term high temperatures up to 400℃, which is far superior to traditional polyester materials. This characteristic enables the customized FPCB to operate reliably in high-temperature industrial furnaces, aerospace engine compartments, and other extreme temperature environments. Meanwhile, its excellent resistance to radiation and chemical corrosion makes it suitable for nuclear power equipment, deep-sea detection instruments, and other harsh application scenarios.

Secondly, it delivers superior electrical performance and structural flexibility. Polyimide has excellent electrical insulation and low dielectric constant, ensuring stable signal transmission even in high-frequency and high-speed electronic systems. Combined with the flexible design of FPCB, the customized solution can be tailored to the spatial constraints of different products, realizing three-dimensional assembly in narrow spaces. Whether it is the ultra-thin circuit design of implantable medical devices or the curved circuit layout of aerospace components, Polyimide Customize FPCB Solution can balance flexibility and structural stability, meeting the personalized needs of diverse high-end products.

Thirdly, it features long-term reliability and durability. Polyimide materials have high mechanical strength and fatigue resistance, which can withstand repeated bending and vibration without damage. In the customized solution, the rational design of circuit traces and the optimization of lamination processes further enhance the service life of the FPCB. This long-term reliability is crucial for electronic products that require maintenance-free operation for a long time, such as aerospace equipment and deep-sea sensors.

Polyimide Customize FPCB Solution has been widely applied in high-end industries with stringent requirements for reliability and environmental adaptability. In the aerospace and aviation field, it is a core component of satellite communication systems, rocket engine control modules, and aircraft avionics. The extreme temperature resistance and radiation resistance of polyimide ensure that the FPCB can operate stably in the harsh cosmic environment and high-altitude flight conditions, safeguarding the normal operation of key equipment.

In the medical device industry, this solution plays a vital role in precision equipment such as minimally invasive surgical instruments, implantable pacemakers, and in-vitro diagnostic devices. Polyimide materials have good biocompatibility and can avoid adverse reactions with human tissues. The customized ultra-thin and flexible FPCB can be seamlessly integrated into small medical devices, realizing stable signal transmission and precise control, which is essential for improving the safety and effectiveness of medical procedures.

In the high-end industrial control sector, Polyimide Customize FPCB Solution is used in industrial furnace temperature sensors, chemical reaction tank monitoring systems, and other equipment. Its resistance to high temperature and chemical corrosion ensures continuous and reliable operation of the circuit in harsh industrial environments, reducing equipment failure rates and improving production efficiency. Additionally, it is also applied in new energy fields such as high-temperature fuel cell components, supporting the development of clean energy technology.

Choosing a reliable provider of Polyimide Customize FPCB Solution is crucial to ensuring product quality and project success. Firstly, assess the provider's material quality control capabilities. High-quality polyimide raw materials are the foundation of the solution, so it is necessary to confirm whether the provider has strict raw material inspection processes and cooperates with reputable material suppliers.

Secondly, evaluate their customized design and technical strength. A professional provider should have an experienced engineering team that can deeply understand the specific needs of different industries and applications, and provide optimized circuit design schemes. They should also be proficient in handling complex processes such as polyimide lamination and high-precision circuit etching to ensure that the customized solution meets performance requirements.

Thirdly, verify their quality certification and testing capabilities. Reliable providers should hold international certifications such as ISO 9001 and aerospace, medical-related industry certifications. They should also have complete testing equipment to conduct strict performance tests on the customized FPCBs, including high-temperature resistance, radiation resistance, and fatigue resistance tests, to ensure product reliability.

Finally, consider their technical support and after-sales service. The application of Polyimide Customize FPCB Solution often involves complex technical issues, so the provider should be able to provide timely technical consultation and on-site support. Perfect after-sales service can also ensure that any problems arising during product use are resolved promptly.

As the high-end electronics industry evolves towards green sustainability and intelligent integration, Polyimide Customize FPCB Solution is also developing in new directions. One key trend is the development of eco-friendly polyimide materials. Manufacturers are researching and developing recyclable polyimide substrates and lead-free production processes to reduce the environmental impact of products, in line with global environmental protection trends.

Another trend is the integration with intelligent technologies. With the development of the Internet of Things (IoT) and artificial intelligence (AI), Polyimide Customize FPCB Solution is gradually integrating smart sensors and wireless communication modules. This enables the FPCB to not only undertake the function of signal transmission but also realize real-time data collection and remote monitoring, expanding its application in smart aerospace, smart medical care, and other fields. Additionally, the development of ultra-thin and ultra-light polyimide materials will further enhance the miniaturization and portability of electronic products.

In conclusion, Polyimide Customize FPCB Solution, relying on the excellent properties of polyimide materials and personalized design capabilities, has become an indispensable support for high-reliability electronic products in extreme environments. Its wide application in aerospace, medical, and high-end industrial fields has driven the innovation and development of the high-end electronics industry. By selecting a reliable solution provider with strict material control, strong technical strength, and perfect after-sales service, enterprises can effectively enhance the performance and competitiveness of their products. As green and intelligent trends deepen, Polyimide Customize FPCB Solution will continue to evolve and play a more critical role in shaping the future of high-end electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB