-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 02. 2025, 11:39:02

As high-end electronic devices evolve toward miniaturization, intelligence, and high performance, the demand for Precision Component FPC Assembly Service has surged dramatically. This specialized service focuses on the accurate assembly of micro-sized, high-precision components—such as microcontrollers, precision sensors, and ultra-small passive components—onto flexible printed circuits (FPCs). Unlike standard FPC assembly, which prioritizes basic connectivity, Precision Component FPC Assembly Service requires rigorous control over component placement accuracy, solder joint integrity, and FPC substrate stability to ensure optimal performance of high-end devices. For industries including precision medical equipment, aerospace electronics, and premium consumer gadgets, this service is a critical cornerstone for translating innovative designs into reliable, market-ready products.

Precision Component FPC Assembly Service delivers unique advantages that address the stringent requirements of high-end flexible electronics:

- Miniaturization Enablement: High-end devices such as wearable health monitors, micro medical implants, and compact aerospace sensors demand ultra-small form factors. This service specializes in assembling precision components with sizes as small as 01005 (0.4mm×0.2mm) or even smaller onto thin, flexible FPC substrates, maximizing component density without sacrificing flexibility. This enables the development of devices that are lightweight, compact, and adaptable to narrow or curved installation spaces.

- Superior Signal Integrity & Performance: Precision components in high-frequency or high-precision systems (e.g., 5G millimeter-wave modules, precision measurement tools) are highly sensitive to assembly errors. The service employs high-precision placement technologies and optimized soldering processes to minimize parasitic capacitance, resistance, and electromagnetic interference (EMI), ensuring stable signal transmission and accurate data output. This level of precision directly enhances the overall performance and functionality of end devices.

- Enhanced Reliability in Harsh Environments: High-end electronic devices often operate in extreme conditions—such as extreme temperatures in aerospace, moisture in medical applications, or vibration in industrial precision equipment. Precision Component FPC Assembly Service uses specialized materials (e.g., high-temperature solder paste, anti-corrosion coatings) and reinforcement techniques (e.g., selective underfill, conformal coating) to strengthen solder joints and protect components, ensuring long-term reliability and durability under harsh operating conditions.

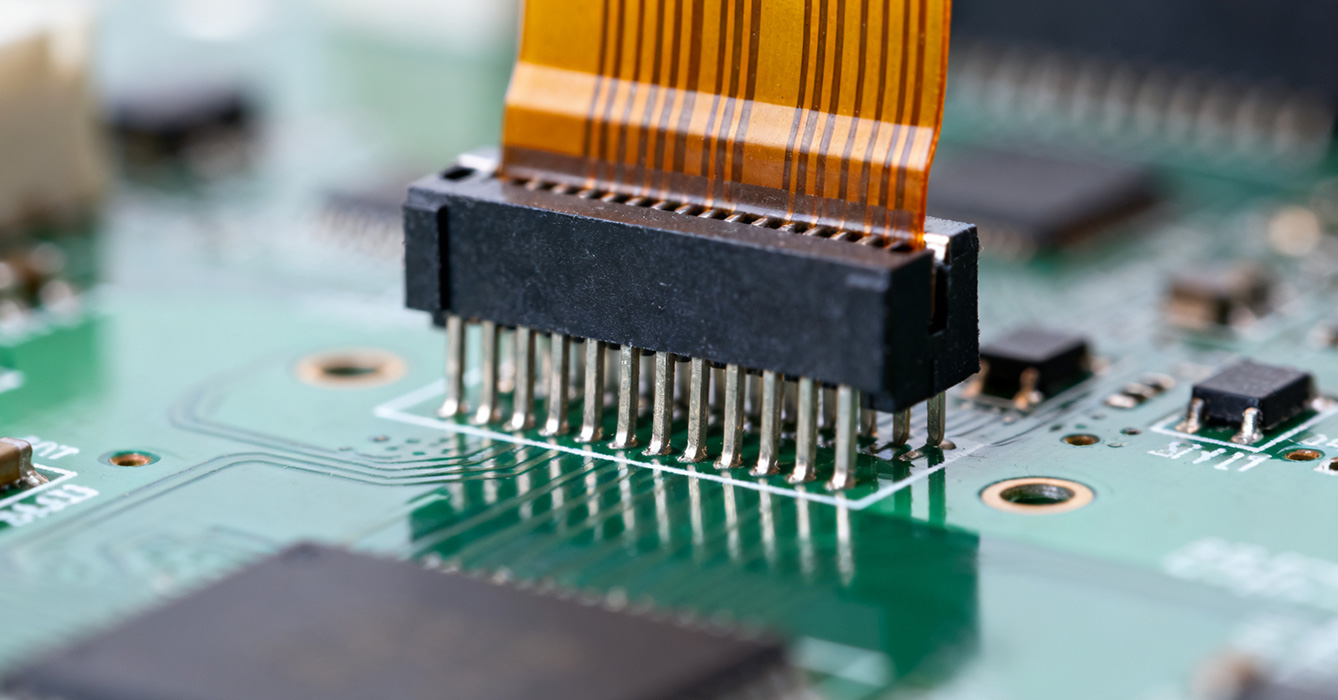

- Compatibility with Complex FPC Designs: The service supports assembly on complex FPC structures, including multi-layer FPCs, rigid-flex FPCs, and FPCs with irregular cutouts. It can accurately align and assemble precision components on curved or uneven FPC surfaces, adapting to the diverse design needs of high-end products such as foldable smartphone hinges, robotic joint sensors, and medical endoscopes.

Assembling precision components on flexible FPCs poses unique technical challenges, which require specialized solutions from professional service providers:

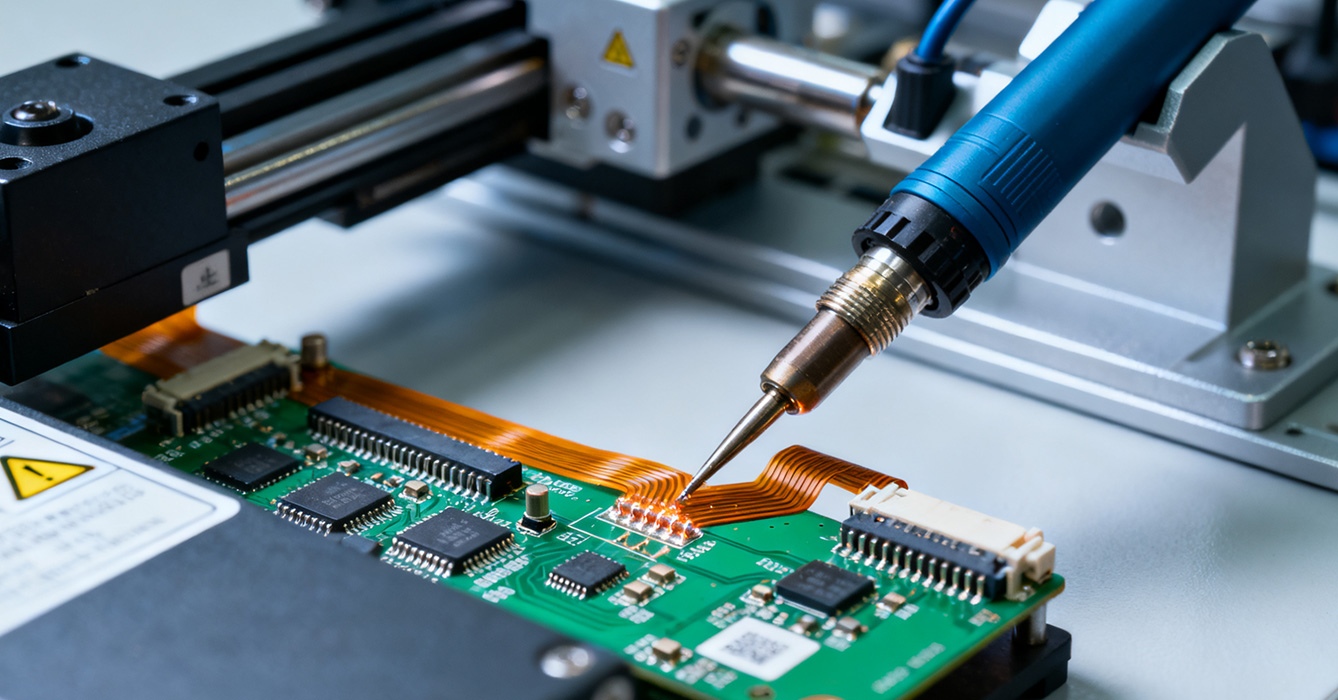

- Precision Component Placement: Micro-sized components are prone to misalignment during assembly, which can cause short circuits or poor connectivity. Service providers use advanced SMT equipment with high-precision vision alignment systems (sub-micron level accuracy) and custom-designed nozzles to ensure accurate placement of each precision component, even on flexible substrates that are prone to slight deformation.

- FPC Substrate Stability Control: FPCs are flexible and easily deform under thermal or mechanical stress during assembly, affecting component placement accuracy. Solutions include using vacuum adsorption fixtures to fix FPCs during processing, optimizing reflow soldering temperature profiles to minimize thermal expansion and contraction, and selecting high-stability FPC substrates with low warpage rates.

- Micro-Soldering Quality Assurance: Solder joints for precision components are extremely small, requiring strict control over solder paste volume and soldering parameters. Service providers adopt micro-solder paste printing technologies (e.g., stencil with ultra-fine apertures) and lead-free solder alloys with excellent ductility to ensure strong, reliable solder joints. They also use automated optical inspection (AOI) and X-ray inspection to detect hidden defects such as insufficient solder, cold joints, or solder bridges.

- Static Electricity Protection: Many precision components (e.g., microchips, sensors) are highly sensitive to static electricity, which can cause permanent damage. The service implements comprehensive anti-static measures, including anti-static workbenches, grounding equipment, ionizers, and static-free packaging, throughout the entire assembly process to eliminate static risks.

This specialized assembly service is indispensable in high-end industries where precision and reliability are non-negotiable:

- Precision Medical Devices: Assembles components for miniaturized implantable sensors (e.g., glucose monitors, pacemaker components), portable diagnostic equipment, and surgical robots. The service ensures biocompatibility of materials, ultra-precise assembly, and compliance with strict medical standards (ISO 13485), safeguarding patient safety and device reliability.

- Aerospace & Defense Electronics: Supports the assembly of precision FPCs for avionics systems, satellite communication modules, and military sensors. The service meets the rigorous requirements of aerospace applications, including radiation resistance, extreme temperature tolerance, and high reliability, ensuring stable operation in harsh space or combat environments.

- Premium Consumer Electronics: Powers high-end products such as foldable smartphones, premium smartwatches, and VR/AR headsets. The service enables the assembly of tiny, high-performance components (e.g., micro-displays, precision motion sensors) onto flexible substrates, enhancing product functionality, portability, and user experience.

- Industrial Precision Sensors & Automation: Assembles FPCs for industrial IoT precision sensors, robotic vision systems, and automated measurement equipment. The service ensures high-precision signal transmission and resistance to industrial harsh environments (dust, humidity, vibration), supporting the digital transformation of smart manufacturing.

In conclusion, Precision Component FPC Assembly Service is a vital enabler of high-end flexible electronics, combining ultra-precise assembly technologies with specialized quality control measures to meet the stringent requirements of modern high-performance devices. By addressing the unique challenges of assembling micro-sized components on flexible substrates, this service elevates product reliability, enables miniaturization, and supports innovation across critical industries. As the demand for more precise, compact, and reliable electronic devices continues to grow, partnering with a professional Precision Component FPC Assembly Service provider will remain a strategic choice for manufacturers seeking to gain a competitive edge in high-end markets.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB