-

- PCB TYPE

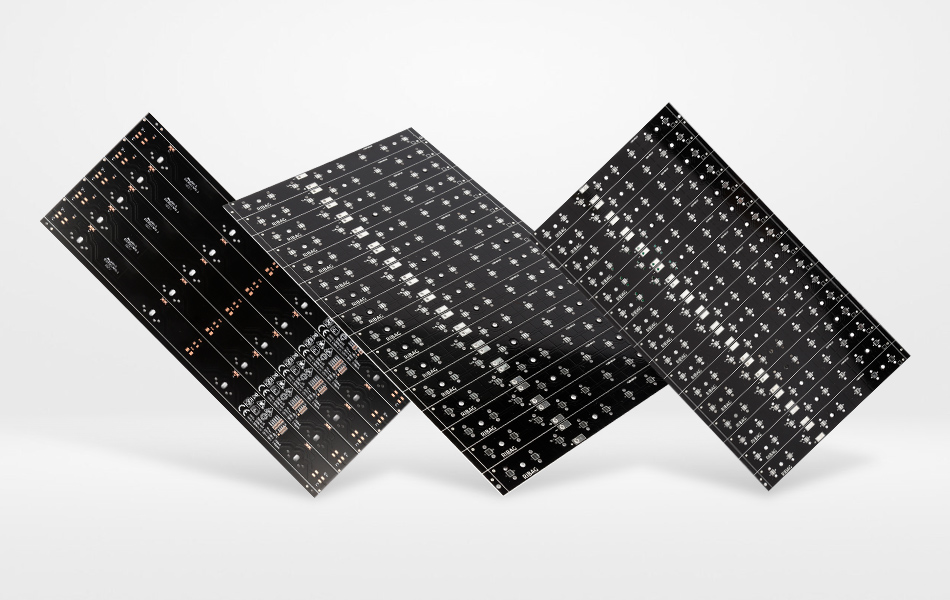

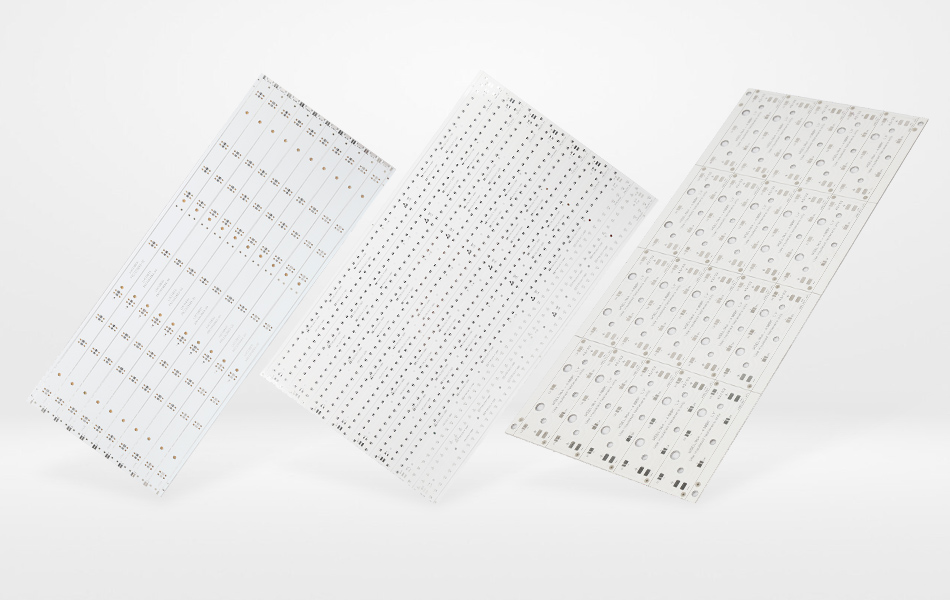

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 26. 2025, 10:31:38

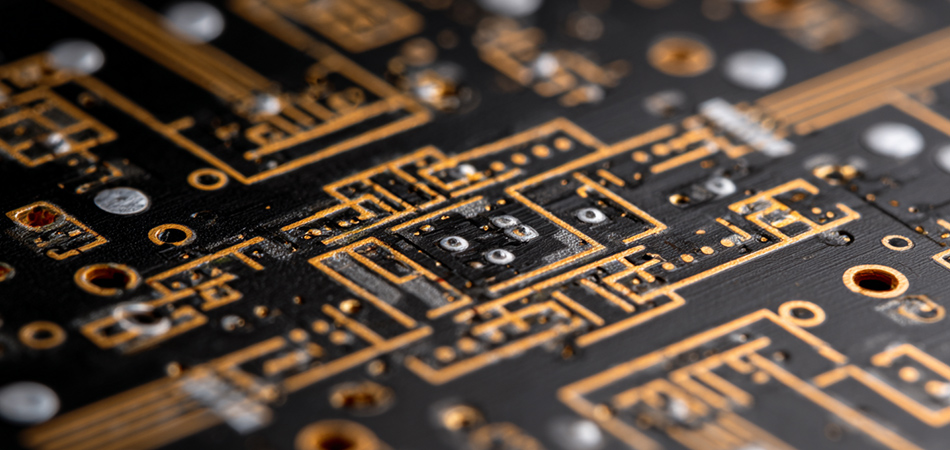

In the intricate world of electronics manufacturing, Aluminum Printed Circuit Boards (Al PCBs) have become indispensable due to their remarkable thermal management capabilities and mechanical strength. Among the various features that contribute to the functionality and reliability of Al PCBs, precision countersink holes play a pivotal role. These holes are not just simple depressions; they are engineered with exacting standards to ensure secure component mounting, optimal electrical performance, and enhanced mechanical integrity.

As electronics continue to evolve towards smaller, more powerful, and more reliable devices, the demand for precision in every aspect of PCB design and manufacturing is on the rise. Precision countersink holes in Al PCBs are at the forefront of this drive for accuracy, enabling the creation of high - quality electronic assemblies that meet the stringent requirements of modern applications. This article will explore the significance, design principles, manufacturing techniques, quality control measures, and applications of precision countersink holes in Al PCBs, highlighting their role in shaping the future of electronics.

The Significance of Precision Countersink Holes in Al PCBs

Secure Component Mounting

Precision countersink holes are essential for ensuring a secure and stable connection when mounting components on Al PCBs. In modern electronics, components are getting smaller and more densely packed, and a reliable mechanical connection is crucial to prevent any movement or loosening during operation. A precisely crafted countersink hole allows a flat - head screw or rivet to fit snugly, with the head sitting flush against the PCB surface. This not only distributes the clamping force evenly across the component but also minimizes the risk of mechanical stress concentrations that could lead to component failure over time.

For example, in high - vibration environments such as automotive or aerospace electronics, a secure connection provided by precision countersink holes can prevent components from detaching, ensuring the continuous and reliable operation of the electronic system. Without precision, even a slight misalignment or improper fit of the fastener in the countersink hole can compromise the integrity of the entire assembly.

Electrical Performance Optimization

In addition to mechanical stability, precision countersink holes can have a significant impact on the electrical performance of Al PCBs. When components are mounted, the fasteners used in countersink holes may also serve as electrical conductors in some cases. A precisely drilled and countersunk hole ensures that the fastener makes optimal electrical contact with the PCB traces, reducing electrical resistance and minimizing the potential for signal interference or electrical noise.

Moreover, the placement and dimensions of precision countersink holes are carefully planned to avoid any interference with nearby electrical traces. This prevents short - circuits and ensures that the electrical signals can flow smoothly through the PCB, maintaining the overall functionality and performance of the electronic device.

Aesthetic and Design Considerations

In consumer electronics and high - end products, aesthetics often play a crucial role. Precision countersink holes contribute to a clean and professional appearance of the PCB assembly. When fasteners are flush - mounted in precisely made countersink holes, the surface of the PCB remains smooth, enhancing the overall visual appeal of the product. This is particularly important for devices where the PCB may be visible to the end - user, such as in some types of computer cases, audio equipment, or decorative lighting fixtures.

Furthermore, a well - designed PCB with precision countersink holes can also facilitate easier assembly and disassembly processes, as the fasteners are more likely to fit correctly the first time, reducing the chances of damaging the PCB or other components during handling.

Design Principles of Precision Countersink Holes in Al PCBs

Hole Dimensions and Tolerances

The dimensions of precision countersink holes, including the diameter of the drilled hole and the depth and angle of the countersink, must be specified with extreme accuracy. The diameter of the drilled hole needs to be precisely matched to the size of the fastener to ensure a snug fit. Any deviation from the ideal diameter can result in either a loose connection or excessive force during installation, both of which can be detrimental to the performance and longevity of the assembly.

Similarly, the depth of the countersink is critical. It should be deep enough to allow the head of the flat - head fastener to sit flush with the PCB surface, but not so deep that it weakens the structural integrity of the PCB. The angle of the countersink also affects the fit and performance of the fastener. Standard angles are commonly used, but in some specialized applications, custom angles may be required to meet specific design requirements.

Tolerances for these dimensions are extremely tight in precision countersink holes. Even a small variation in the dimensions can lead to significant issues in the assembly. Manufacturers typically adhere to strict industry standards and specifications to ensure that the countersink holes meet the required precision levels.

Material Compatibility and Interaction

Al PCBs consist of multiple materials, including the aluminum substrate, dielectric layer, and copper traces. When designing precision countersink holes, it is essential to consider the compatibility of these materials with the fasteners and any additional materials used in the mounting process.

For instance, different metals used for fasteners may react with the aluminum substrate, leading to galvanic corrosion. To mitigate this risk, designers may choose fasteners made of materials that are less likely to cause corrosion or apply protective coatings. Additionally, the countersinking process should not damage the dielectric layer, as this could compromise the electrical insulation properties of the PCB. Special care must be taken to ensure that the mechanical stress induced during the creation of the countersink hole does not cause any cracks or delamination in the PCB layers.

Placement and Layout Optimization

The placement of precision countersink holes on the Al PCB is a carefully planned process. From a mechanical perspective, the holes should be positioned in areas that can withstand the forces exerted by the fasteners without causing excessive stress on the PCB or the mounted components. This may involve avoiding areas near sensitive components, such as integrated circuits or delicate sensors, and ensuring that the holes are distributed evenly to provide balanced support.

For electrical performance, the layout of the countersink holes must be optimized to avoid interfering with the copper traces and electrical pathways. Adequate clearance needs to be maintained between the holes and the traces to prevent electrical short - circuits or signal degradation. In complex PCB designs, computer - aided design (CAD) software is often used to simulate the placement of countersink holes and ensure that they meet both mechanical and electrical requirements.

Manufacturing Techniques for Precision Countersink Holes in Al PCBs

Advanced Drilling Technologies

The manufacturing of precision countersink holes in Al PCBs begins with the drilling of the initial hole. High - end drilling machines equipped with advanced technologies are employed for this task. These machines can achieve extremely high levels of accuracy in terms of hole location, diameter, and depth.

One such technology is laser drilling. Laser - based drilling systems use a focused laser beam to ablate the material, creating holes with very tight tolerances. Laser drilling offers several advantages, including the ability to drill small - diameter holes with high precision, minimal heat - affected zones, and the flexibility to create complex hole patterns. Another popular method is mechanical drilling using high - speed spindles and specialized drill bits. These drill bits are made of high - quality materials, such as carbide, and are designed to cut through the aluminum substrate and dielectric layer with minimal burr formation and accurate hole dimensions.

Precision Countersinking Processes

After drilling the initial hole, the countersinking process is carried out. Mechanical countersinking tools have evolved to offer higher precision and repeatability. These tools are often computer - controlled, allowing for precise adjustment of the countersink depth, angle, and speed. The cutting edges of the countersinking tools are designed to provide a smooth and accurate conical depression, ensuring a perfect fit for the fastener.

In some cases, electrochemical machining (ECM) may be used for precision countersinking. ECM is a non - traditional machining process that uses an electrolyte solution and an electric current to remove material from the PCB. This method can achieve extremely high precision and surface finish, making it suitable for applications where the highest levels of accuracy are required. However, ECM is more complex and expensive compared to traditional mechanical countersinking methods.

In - Process Monitoring and Control

To ensure the precision of countersink holes during the manufacturing process, in - process monitoring and control systems are essential. These systems use sensors and advanced imaging technologies to continuously measure the dimensions of the holes as they are being drilled and countersunk.

For example, optical sensors can be used to detect the position and size of the hole in real - time, and any deviations from the set parameters can be immediately corrected. Similarly, force sensors can be employed to monitor the forces applied during the drilling and countersinking processes, ensuring that the correct amount of pressure is used to avoid damaging the PCB or creating inconsistent hole dimensions. This in - process monitoring helps to maintain the high level of precision required for modern electronics manufacturing.

Quality Control Measures for Precision Countersink Holes in Al PCBs

Dimensional Inspection

Dimensional inspection is a critical part of quality control for precision countersink holes. High - precision measuring instruments, such as coordinate measuring machines (CMMs) and optical profilometers, are used to measure the diameter of the drilled hole, the depth of the countersink, and the angle of the countersink with great accuracy.

CMMs use touch - probes or non - contact sensors to measure the physical dimensions of the holes, while optical profilometers use advanced imaging techniques to create 3D models of the holes and analyze their geometry. These measurements are compared to the design specifications, and any holes that do not meet the required tolerances are rejected or sent for rework.

Visual Inspection and Defect Detection

Visual inspection is also an important quality control step. Trained inspectors carefully examine the countersink holes for any visible defects, such as burrs, cracks, or uneven surfaces. Burrs can interfere with the proper seating of the fastener and may also pose a risk to the electrical insulation of the PCB. Cracks in the PCB around the countersink hole can weaken the structural integrity of the board.

Automated optical inspection (AOI) systems can also be used to perform more efficient and accurate visual inspections. These systems use cameras and image - processing algorithms to detect even the smallest defects, ensuring that only high - quality PCBs with precision countersink holes are passed on to the next stage of production.

Functional Testing

In addition to dimensional and visual inspections, functional testing may be carried out to ensure that the precision countersink holes do not affect the electrical and mechanical functionality of the PCB. For electrical testing, the PCB may be subjected to tests such as continuity testing, insulation resistance testing, and signal integrity testing to verify that the countersink holes have not caused any electrical problems.

Mechanical functional testing may involve applying simulated forces to the mounted components to check the strength and stability of the connection provided by the countersink holes. This type of testing helps to ensure that the PCBs will perform reliably in real - world applications.

Applications of Precision Countersink Holes in Al PCBs

Aerospace and Defense Electronics

In the aerospace and defense industries, where reliability and performance are of utmost importance, precision countersink holes in Al PCBs are widely used. In avionics systems, which are responsible for navigation, communication, and control in aircraft, components need to be mounted with extreme precision. The harsh operating conditions, including high altitudes, extreme temperatures, and vibrations, demand a secure and stable connection provided by precision countersink holes.

These holes also play a crucial role in defense electronics, such as missile guidance systems and radar systems. The high - reliability requirements of these applications mean that even the smallest deviation in the countersink hole dimensions can lead to system failures. Precision countersink holes ensure that the components remain firmly in place, enabling the accurate operation of these critical defense systems.

Medical Electronics

Medical devices require the highest levels of precision and reliability. Precision countersink holes in Al PCBs are used in a variety of medical electronics, from diagnostic equipment to implantable devices. In diagnostic devices, such as MRI machines or ECG monitors, the proper mounting of components using precision countersink holes is essential for accurate signal acquisition and processing.

For implantable medical devices, the biocompatibility of the materials used, including the fasteners in the countersink holes, is of great concern. Precision manufacturing ensures that the countersink holes are made with the right dimensions and surface finish to accommodate biocompatible fasteners, while also maintaining the integrity of the PCB to ensure the long - term functionality of the implant.

High - End Consumer Electronics

In high - end consumer electronics, such as premium smartphones, tablets, and laptops, precision countersink holes contribute to both the performance and aesthetics of the products. These devices often have complex internal layouts with a large number of components that need to be mounted securely. Precision countersink holes allow for a more compact and efficient design, as components can be placed closer together without the risk of interference from protruding fasteners.

The smooth and clean appearance provided by flush - mounted fasteners in precision countersink holes also enhances the overall user experience, as it gives the device a more premium and professional look. Additionally, the reliable mechanical and electrical connections provided by these holes ensure the long - term performance and durability of the consumer electronics.

Future Trends and Challenges

Miniaturization and Increased Precision Requirements

As the electronics industry continues to strive for smaller and more powerful devices, the demand for even higher levels of precision in countersink holes will increase. Miniaturization means that components are getting smaller, and the tolerances for the holes need to be tightened further. This will require the development of new manufacturing technologies and tools that can achieve sub - micrometer levels of accuracy.

Designers will also face the challenge of optimizing the layout of precision countersink holes in extremely small PCBs, where every millimeter of space matters. Advanced simulation and design software will play a crucial role in helping designers meet these challenges and create efficient and reliable PCB designs.

Integration of New Materials and Technologies

The integration of new materials, such as advanced composites and nanomaterials, into Al PCBs may require new approaches to the design and manufacturing of precision countersink holes. These materials may have different mechanical and electrical properties, which could affect the way the holes are drilled and countersunk.

Moreover, emerging technologies, such as 3D printing for PCBs and the Internet of Things (IoT) - enabled smart manufacturing, will bring new opportunities and challenges. 3D - printed PCBs may require a different set of techniques for creating precision countersink holes, while IoT - enabled manufacturing will allow for more real - time monitoring and control of the production process to ensure higher precision and quality.

Environmental Sustainability

With the growing focus on environmental sustainability, the electronics manufacturing industry is under pressure to reduce its environmental impact. This includes the development of more eco - friendly manufacturing processes for precision countersink holes in Al PCBs. Manufacturers will need to explore ways to reduce the use of hazardous chemicals in the drilling and countersinking processes, as well as improve the recycling and disposal of PCBs at the end of their life cycle.

Finding sustainable solutions that do not compromise the precision and quality of the countersink holes will be a significant challenge in the coming years.

Conclusion

Precision countersink holes in Al PCBs are a vital component in the modern electronics manufacturing landscape. They are essential for ensuring secure component mounting, optimizing electrical performance, and enhancing the overall quality and reliability of electronic assemblies. Through careful design, advanced manufacturing techniques, and strict quality control measures, these precision holes enable the creation of high - end electronic products that meet the demanding requirements of various industries.

As the electronics industry continues to evolve, the importance of precision countersink holes in Al PCBs will only increase. Addressing the future trends and challenges, such as miniaturization, integration of new materials and technologies, and environmental sustainability, will be crucial for maintaining the competitiveness of the electronics manufacturing sector. By staying at the forefront of innovation in the design and production of precision countersink holes, manufacturers can continue to drive the development of advanced and reliable electronic devices that shape our modern world.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB