-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 06. 2025, 09:38:22

Precision Electromechanical Assembly is a specialized discipline focused on integrating mechanical components, electrical circuits, and micro-systems with sub-micron to micron-level tolerance—catering to applications where even the smallest misalignment can compromise performance or safety. Unlike standard industrial electromechanical assembly, which prioritizes durability for harsh environments, this field demands ultra-fine precision in component placement, alignment, and functional synergy. It underpins the functionality of high-tech systems, from semiconductor lithography machines to medical diagnostic equipment and aerospace guidance systems. As industries push toward miniaturization and high-performance computing, precision electromechanical assembly has become a bottleneck technology, enabling innovations that rely on seamless interaction between mechanical motion and electronic control. This article explores its defining characteristics, core processes, niche applications, and technological advancements.

Three traits distinguish precision electromechanical assembly from conventional practices:

- Sub-Micron Tolerance Control: Components are positioned with accuracy ranging from 0.1 to 10 microns (comparable to the diameter of a human hair). For example, a robotic arm in semiconductor manufacturing requires axis alignment within 2 microns to ensure precise wafer processing.

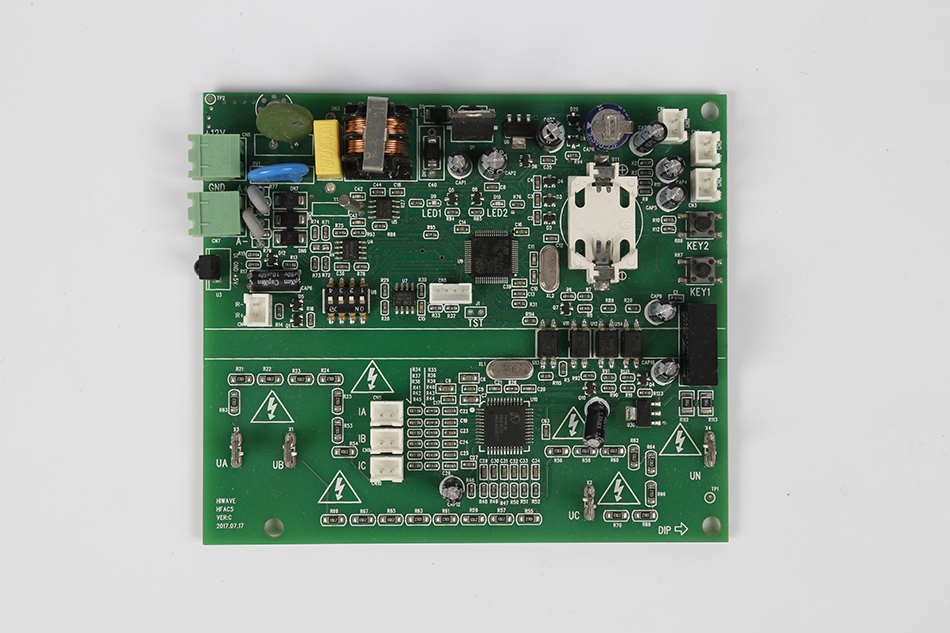

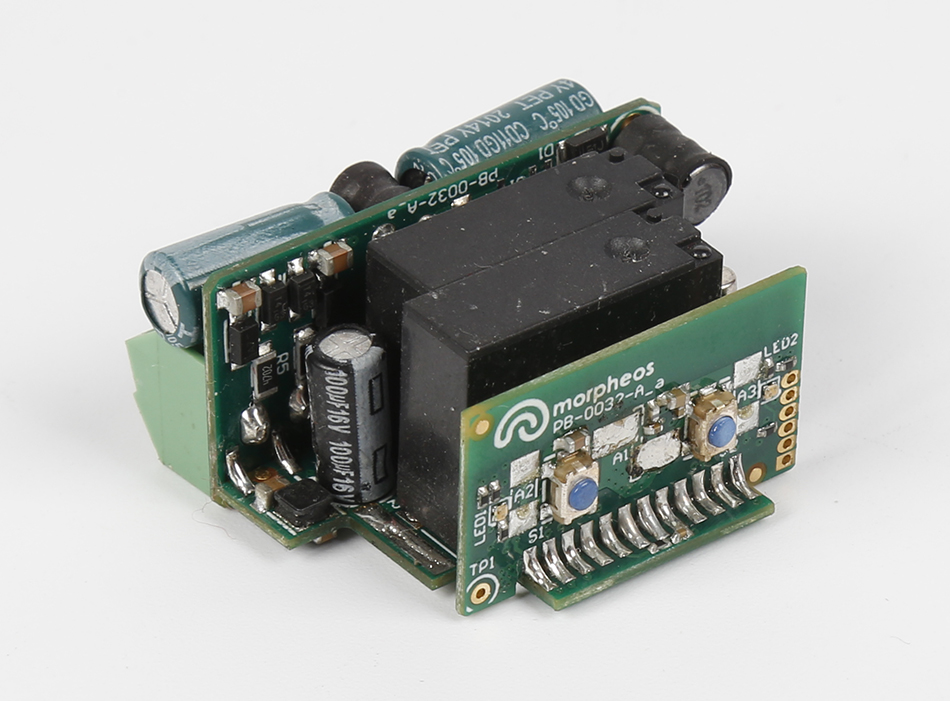

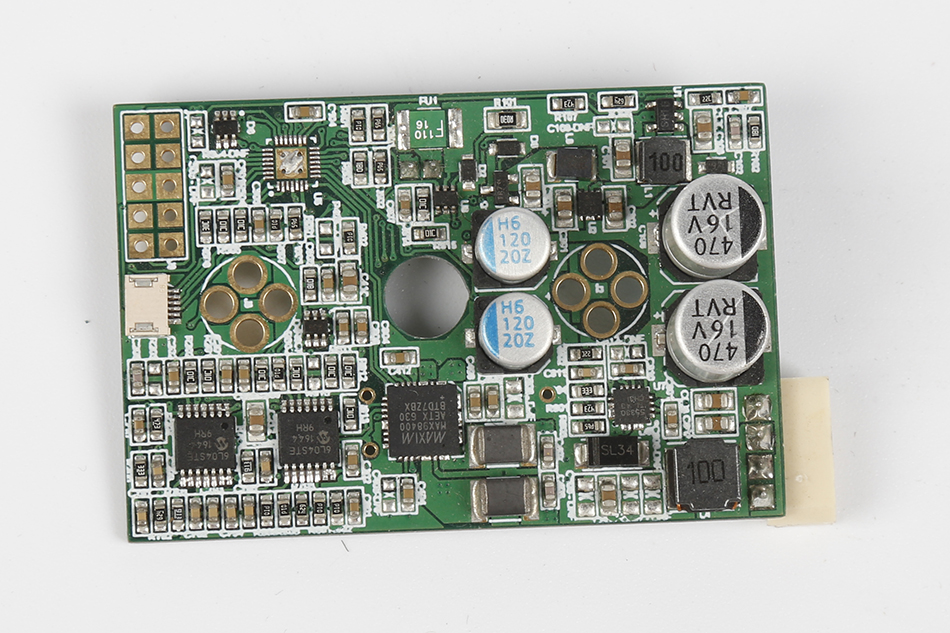

- Multi-Disciplinary Micro-Integration: It combines mechanical engineering (micro-gears, piezoelectric actuators), electrical engineering (flexible PCBs, micro-sensors), and materials science (low-outgassing polymers, precision ceramics) to build compact, high-performance systems.

- Environmental Sensitivity Management: Assemblies are highly susceptible to temperature fluctuations, humidity, and vibration. Thus, processes are conducted in controlled environments (cleanrooms, temperature-stabilized labs) to minimize external interference.

The workflow prioritizes meticulous planning and state-of-the-art equipment to achieve micron-level precision:

Engineers use multi-physics simulation tools to model interactions between mechanical motion and electrical signals at micro-scales. Finite Element Analysis (FEA) predicts stress in tiny components, while Computational Fluid Dynamics (CFD) optimizes heat dissipation for micro-electronics. 3D optical scanning verifies design-to-manufacturing alignment before physical assembly begins.

Assembly relies on specialized equipment: piezoelectric-driven positioning stages for nanometer-scale adjustments, laser alignment systems to calibrate component orientation, and micro-joining techniques (laser welding, ultrasonic bonding) that avoid thermal damage to delicate parts. Wiring uses ultra-fine gauge conductors (down to 36 AWG) routed through micro-channels to minimize signal interference.

Post-assembly testing uses high-precision metrology tools: laser interferometers to measure linear/rotational accuracy, atomic force microscopes (AFMs) to inspect surface finishes, and signal integrity analyzers to validate electrical performance. Calibration is done against national standards (e.g., NIST-traceable references) to ensure long-term measurement stability.

Lithography machines, which print microcircuits on wafers, depend on precision electromechanical assemblies for their stage systems. These assemblies move wafers with nanometer accuracy, synchronized with laser beams, to create 7nm and smaller chip features.

Surgical robots (e.g., minimally invasive da Vinci systems) and diagnostic tools (atomic force microscopes for cellular imaging) use precision assemblies to translate surgeon inputs into sub-millimeter movements or capture high-resolution biological data. These assemblies must balance precision with biocompatibility and sterility.

Inertial navigation systems (INS) and satellite communication terminals rely on precision electromechanical assemblies. For example, an INS’s gyroscopes and accelerometers are assembled with 1-micron alignment to maintain navigation accuracy over long flights without GPS signals.

- AI-Powered Precision Calibration: Machine learning algorithms analyze metrology data to auto-correct minor misalignments in real time, reducing manual calibration time by 60%.

- MEMS Integration: Micro-Electro-Mechanical Systems (MEMS) components (e.g., micro-mirrors, pressure sensors) are being integrated directly into assemblies, enabling smaller, more efficient systems.

- Cleanroom Automation: Autonomous robotic arms with vision-guided precision now perform assembly tasks in Class 1 cleanrooms, eliminating human-induced contamination and variability.

Precision Electromechanical Assembly is the unsung hero of cutting-edge technology, enabling the miniaturization and high performance of systems that define modern industry and healthcare. Its focus on micron-level accuracy, multi-disciplinary integration, and environmental control makes it irreplaceable for applications where "close enough" is not sufficient. As demands for smaller, faster, and more reliable devices grow—from quantum computing to personalized medicine—this field will continue to push the boundaries of what’s possible, leveraging advanced tools and AI to achieve even greater precision. For manufacturers, mastering precision electromechanical assembly is the key to unlocking the next generation of technological breakthroughs.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB