-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 30. 2025, 18:55:28

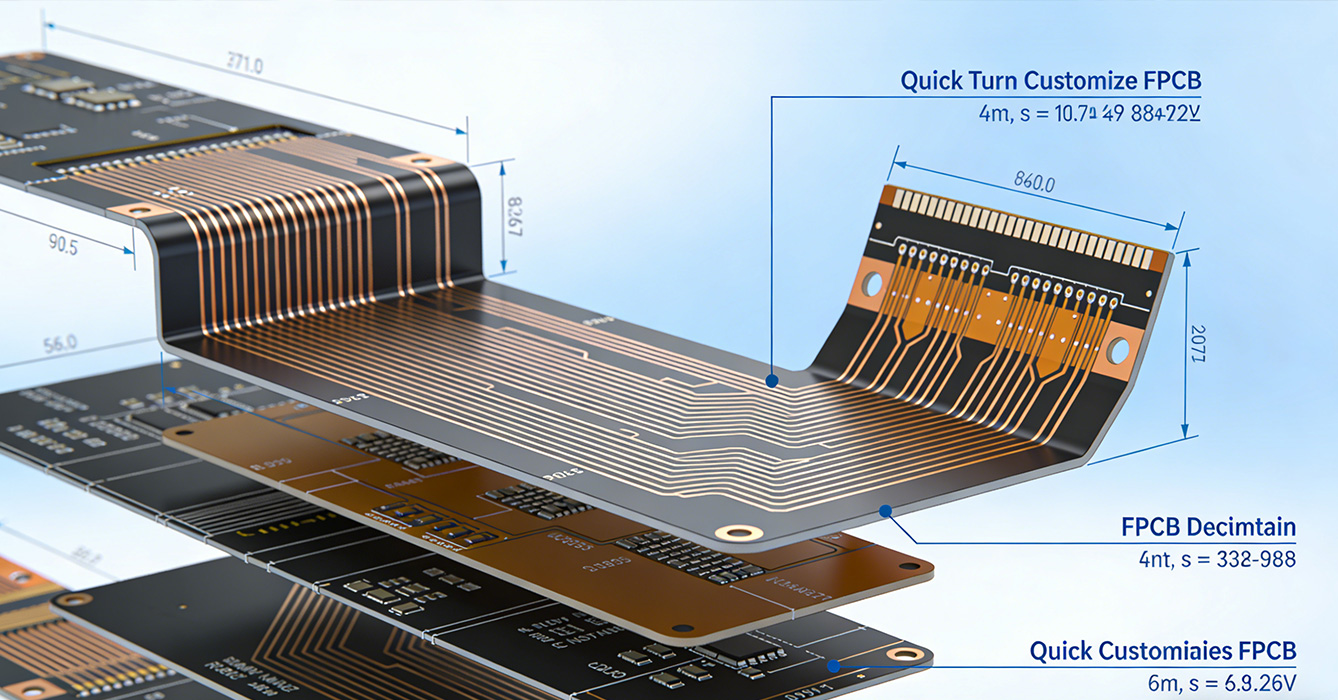

In the fast-paced electronic product development landscape, the ability to quickly validate design concepts and respond to market changes has become a key competitive advantage. Quick Turn Customize FPCB Service emerges as a critical enabler, addressing the core pain points of long lead times and inflexible solutions in traditional FPCB manufacturing. This service combines rapid turnaround capabilities with tailored design support, allowing electronic manufacturers and R&D teams to obtain customized flexible printed circuit boards (FPCBs) in a shortened timeframe without compromising quality. From small-batch prototyping to urgent production needs, Quick Turn Customize FPCB Service empowers innovators to accelerate product development cycles, reduce time-to-market, and gain an edge in the highly competitive electronics industry.

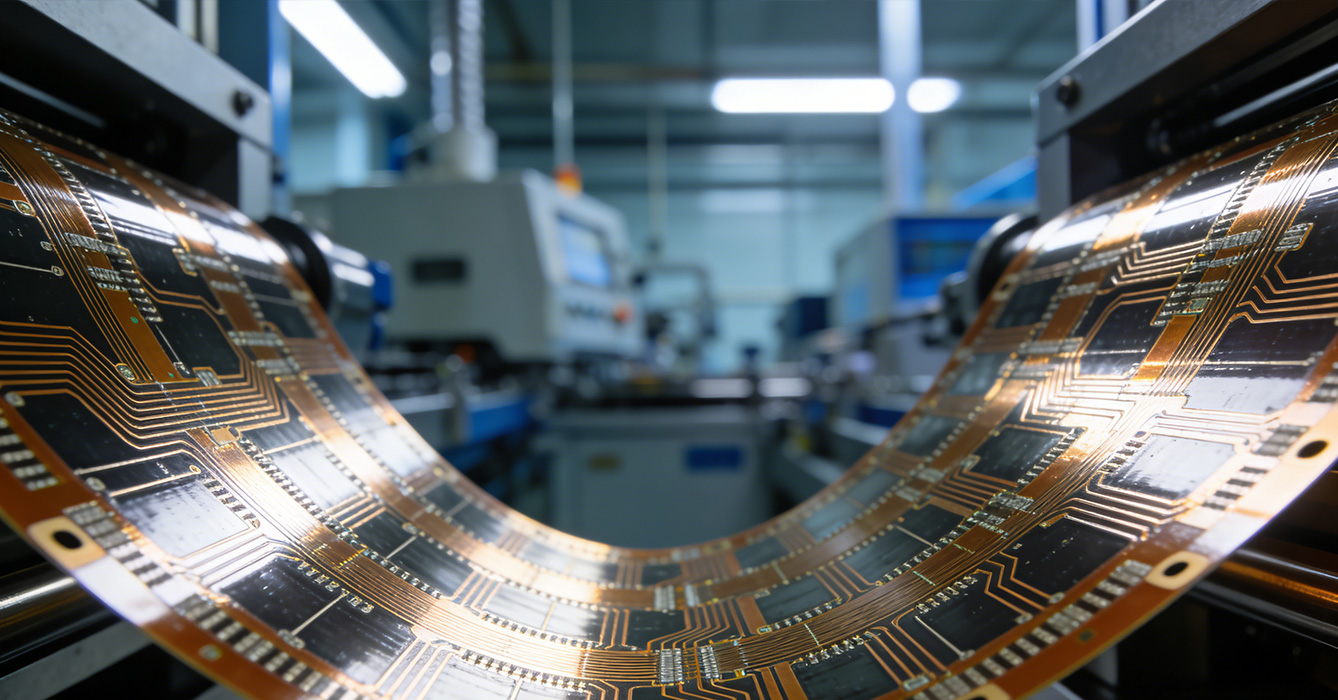

The value of Quick Turn Customize FPCB Service lies in its synergistic integration of speed and customization, which solves two major challenges in electronic R&D and production. Firstly, it delivers rapid turnaround to meet time-sensitive demands. Unlike traditional FPCB manufacturing that requires lengthy setup and production cycles, professional quick-turn services optimize every link of the process—from design review to final delivery. By streamlining workflows, establishing dedicated rapid production lines, and maintaining sufficient stock of core materials, they can significantly shorten the lead time for customized FPCBs, enabling clients to quickly validate design ideas and advance project schedules.

Secondly, it offers flexible customization capabilities to adapt to diverse application needs. Every electronic product has unique spatial constraints, performance requirements, and operating environments, and Quick Turn Customize FPCB Service excels at tailoring solutions accordingly. Whether it is a ultra-thin FPCB for medical endoscopes, a flexible circuit for wearable devices that requires excellent bending resistance, or a high-temperature resistant FPCB for automotive electronics, the service can adjust material selection, circuit layout, and structural design to meet specific needs. Additionally, professional technical teams provide real-time design support, offering manufacturability advice to optimize designs and avoid rework, further enhancing the efficiency of customization.

Quick Turn Customize FPCB Service has been widely adopted across multiple industries, becoming a vital support for innovation in time-critical projects. In the medical device industry, it plays a crucial role in the R&D and emergency production of precision equipment. For example, when a manufacturer of minimally invasive surgical instruments encounters design flaws in FPCBs that lead to project delays, Quick Turn Customize FPCB Service can rapidly adjust the design and deliver customized samples, helping to resume project progress and ensure timely product launch.

In the consumer electronics sector, where product iteration is extremely fast, this service enables brands to accelerate the development of new products such as foldable smartphones, smart wearables, and wireless audio devices. By quickly providing customized FPCBs that match the innovative form factors of these products, it helps brands shorten the R&D cycle and seize market opportunities. The aerospace and drone industries also benefit significantly—when facing urgent orders for satellite components or drone control systems, Quick Turn Customize FPCB Service can meet the high-reliability and rapid-delivery requirements of these critical applications.

Furthermore, in the industrial IoT field, the service supports the rapid deployment of sensor networks. Customized FPCBs that can adapt to harsh industrial environments are delivered quickly, enabling enterprises to accelerate the construction of smart production systems and improve operational efficiency.

Choosing a reliable Quick Turn Customize FPCB Service provider is crucial to ensuring project success. Firstly, evaluate the provider’s rapid delivery capability and stability. It is essential to confirm their historical delivery records, whether they have dedicated rapid production lines, and whether they can maintain consistent quality while ensuring speed. Client testimonials and case studies can provide valuable references for this assessment.

Secondly, assess their technical strength and customization capabilities. A professional service provider should have an experienced engineering team that can quickly understand client needs and provide optimized design solutions. They should also be proficient in handling various complex customization requirements, such as special material selection and high-precision circuit design. Additionally, quality control systems are non-negotiable—rigorous testing processes, from raw material inspection to final product validation, ensure that the customized FPCBs meet performance and reliability standards.

Finally, consider the provider’s service quality and responsiveness. Timely communication and technical support are critical in quick-turn projects. A service provider that offers 24/7 technical consultation and real-time progress updates can effectively address potential issues and ensure smooth project execution.

As the electronics industry continues to evolve, Quick Turn Customize FPCB Service is moving toward digitalization and intelligence to enhance its competitive edge. One key trend is the integration of digital design and production platforms. By adopting cloud-based design tools and digital workflow management systems, service providers can realize real-time collaboration between clients and engineering teams, accelerating design reviews and modification processes. Automated production technologies such as AI-driven process optimization and robotic assembly are also being widely adopted to further improve production efficiency and consistency.

Another trend is the expansion of green and sustainable services. More service providers are adopting eco-friendly materials and lead-free production processes to meet global environmental protection requirements. Additionally, the development of recyclable FPCB materials and energy-efficient production technologies is helping to reduce the environmental impact of customized FPCB manufacturing.

In conclusion, Quick Turn Customize FPCB Service has become an indispensable support for electronic product innovation, offering a perfect combination of speed and customization. Its ability to solve time-sensitive and personalized needs has made it widely popular in medical, consumer electronics, aerospace, and industrial IoT industries. By selecting a reliable service provider with strong technical strength, stable delivery capabilities, and high-quality service, enterprises can effectively accelerate product development cycles and enhance market competitiveness. As digitalization and sustainability trends continue to deepen, Quick Turn Customize FPCB Service will undergo continuous upgrading, playing an even more critical role in driving the innovation and development of the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB