-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 20. 2025, 09:07:46

In the fast - paced electronics industry, time - to - market can be the decisive factor between success and obsolescence. Quick Turn Single Layer Al PCBs have emerged as a crucial enabler, offering a rapid solution for prototyping and small - batch production. Combining the inherent benefits of aluminum substrates with the agility of quick - turn manufacturing, these PCBs are revolutionizing how engineers and designers bring their concepts to life. This article delves into the intricacies of Quick Turn Single Layer Al PCBs, exploring their defining characteristics, design considerations, manufacturing processes, diverse applications, market dynamics, and future trends.

Defining Quick Turn Single Layer Al PCBs

The Concept of Quick Turn Manufacturing

Quick turn manufacturing in the PCB industry refers to the expedited production of printed circuit boards, typically within a significantly shorter timeframe compared to standard manufacturing lead times. This approach caters to the urgent needs of product developers, allowing for rapid prototyping, design validation, and small - scale production runs. It eliminates the long waiting periods associated with traditional PCB manufacturing, enabling faster iterations and quicker product launches.

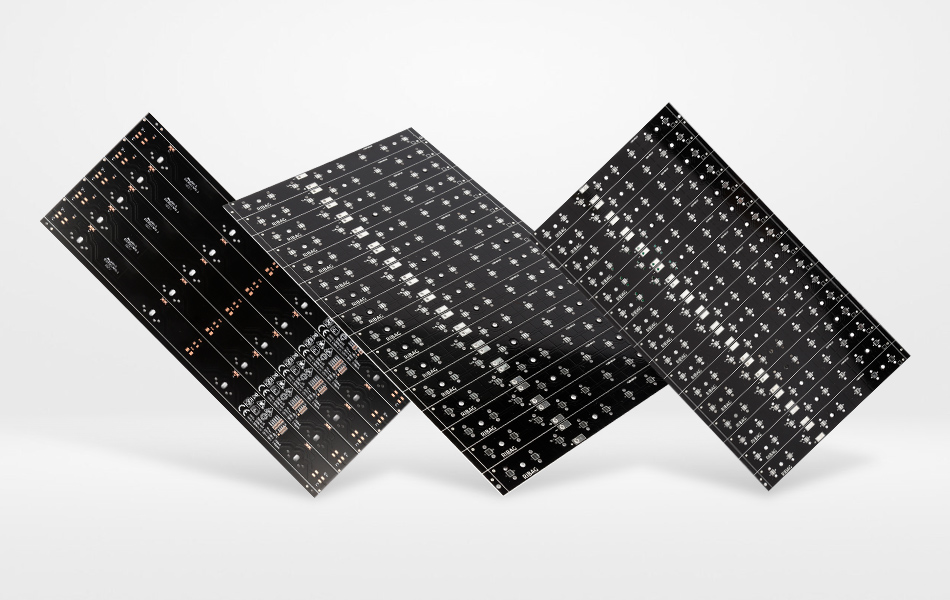

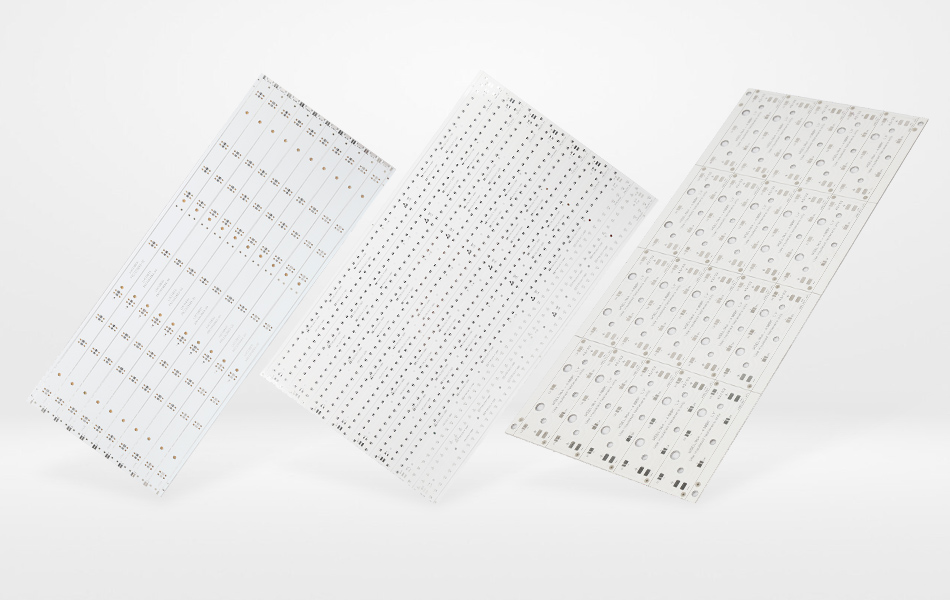

Characteristics of Single Layer Al PCBs

Single layer Al PCBs, with their aluminum substrates, provide several key advantages. The aluminum base offers excellent thermal conductivity, effectively dissipating heat generated by electronic components. This thermal management property is crucial for maintaining component reliability and performance. Additionally, aluminum provides mechanical strength while keeping the PCB lightweight, making it suitable for a wide range of applications. When combined with the quick turn manufacturing process, these inherent features of single layer Al PCBs are harnessed to deliver fast and efficient solutions.

The Synergy of Quick Turn and Single Layer Al PCBs

The combination of quick turn manufacturing and single layer Al PCBs creates a powerful solution. For product developers, it means being able to quickly test and refine their designs. The quick turn aspect allows for rapid production of prototypes, enabling engineers to identify and correct design flaws early in the development cycle. Meanwhile, the single layer Al PCB structure provides the necessary performance in terms of thermal management and electrical conductivity, ensuring that the prototypes accurately represent the intended final product's functionality.

Design Considerations for Quick Turn Single Layer Al PCBs

Simplified Circuit Design

Given the single - layer nature of these PCBs, circuit design must be carefully planned to optimize functionality within the constraints. Designers need to focus on creating straightforward yet effective electrical pathways. This often involves minimizing the complexity of the circuit layout, avoiding unnecessary trace crossovers, and ensuring that all components can be properly interconnected on a single layer. Special attention is paid to power and ground distribution to maintain a stable electrical supply.

Thermal Management Optimization

Since thermal management is a key advantage of Al PCBs, optimizing it in the design phase is essential. Component placement plays a vital role; heat - generating components should be positioned to maximize heat transfer to the aluminum substrate. Thermal vias, if necessary, need to be strategically placed to enhance heat dissipation. The design should also consider the natural or forced - air cooling mechanisms available in the final application environment to ensure effective heat removal.

Design for Manufacturability

For quick turn production, design for manufacturability (DFM) is of utmost importance. Designers must be aware of the manufacturing capabilities and limitations of quick turn PCB manufacturers. This includes considerations such as minimum trace width and spacing that the manufacturing process can handle, as well as the ease of component placement and soldering. By adhering to DFM principles, potential manufacturing issues can be avoided, ensuring a smooth and rapid production process.

Manufacturing Processes for Quick Turn Single Layer Al PCBs

Streamlined Material Selection and Preparation

Quick turn manufacturers focus on using readily available materials to expedite the production process. High - quality aluminum sheets with consistent properties are sourced for the substrate. Copper foil for the traces is selected based on its electrical conductivity and compatibility with the manufacturing process. The thermally conductive dielectric material is chosen for its reliable electrical insulation and good adhesion properties. All materials are quickly inspected and prepared for the subsequent manufacturing steps.

Accelerated Lamination

The lamination process, which bonds the aluminum substrate, dielectric layer, and copper foil together, is optimized for speed without sacrificing quality. Advanced lamination equipment and carefully calibrated parameters ensure that the layers are bonded firmly in a shorter time frame. Specialized techniques may be employed to reduce the curing time of the dielectric material while maintaining its integrity and performance.

Precision Drilling and Plating

High - speed drilling machines are used to create holes for component mounting and electrical connections with precision and speed. The plating process, typically electroplating, is carefully controlled to deposit a uniform and reliable copper layer on the holes and traces. Manufacturers may use advanced plating solutions and techniques to accelerate the plating process while ensuring the required thickness and quality of the copper deposit.

Rapid Circuit Patterning

Photolithography, the process of creating the electrical circuits on the copper layer, is optimized for quick turn production. High - resolution masks and efficient exposure systems are used to reduce the time required for pattern transfer. The development and etching processes are also fine - tuned to remove the unwanted copper quickly and accurately, leaving behind the precisely patterned traces.

Applications of Quick Turn Single Layer Al PCBs

Prototyping and Product Development

One of the primary applications of Quick Turn Single Layer Al PCBs is in prototyping. Engineers and designers can quickly obtain functional prototypes of their electronic designs, allowing for rapid testing and validation. This is particularly valuable in industries such as consumer electronics, where product development cycles are short, and the ability to quickly iterate on designs is crucial for staying competitive. Quick turn PCBs enable companies to bring new products to market faster, reducing the time from concept to commercialization.

Small - Batch Production

For small - batch production runs, Quick Turn Single Layer Al PCBs offer a cost - effective and efficient solution. Small - scale manufacturers or companies looking to test the market with a limited production volume can utilize these PCBs. The quick turn aspect allows for a faster production turnaround, reducing inventory holding costs and enabling a quicker response to market demands. It is also suitable for custom - made electronic products, where each batch may have unique requirements.

Research and Development

In research and development settings, Quick Turn Single Layer Al PCBs are invaluable. Scientists and researchers can quickly fabricate PCBs for experimental setups, allowing for rapid exploration of new technologies and concepts. The ability to quickly produce customized PCBs tailored to specific research needs accelerates the pace of innovation, enabling faster discovery and development in fields such as electronics, robotics, and IoT.

Market Dynamics of Quick Turn Single Layer Al PCBs

Market Growth Drivers

The market for Quick Turn Single Layer Al PCBs is experiencing significant growth, driven by several factors. The increasing demand for rapid prototyping and short - cycle product development across various industries is a major catalyst. As companies strive to reduce time - to - market and gain a competitive edge, the need for quick turn PCB solutions is on the rise. Additionally, the growth of the IoT, wearables, and other emerging technologies, which require frequent design iterations and small - scale production, is fueling the market expansion.

Competitive Landscape

The market is highly competitive, with a mix of established PCB manufacturers and specialized quick turn PCB providers. Key players differentiate themselves through factors such as turnaround time, product quality, cost - effectiveness, and customer service. Established manufacturers may leverage their existing infrastructure and expertise, while specialized quick turn providers focus on optimizing their processes for speed and flexibility. Competition also drives continuous innovation in manufacturing techniques and service offerings to meet the evolving needs of customers.

Challenges and Future Trends

Challenges

Despite their benefits, Quick Turn Single Layer Al PCBs face several challenges. Maintaining high - quality standards while reducing production times can be difficult. The need to source materials quickly may sometimes lead to limitations in material selection or higher costs. Additionally, ensuring consistent performance across multiple quick turn production runs can be a challenge, especially when dealing with complex designs or demanding applications.

Future Trends

The future of Quick Turn Single Layer Al PCBs looks promising, with several trends on the horizon. Advancements in digital manufacturing technologies, such as 3D printing and automated assembly, are likely to further streamline the production process, reducing turnaround times even more. The development of new materials with enhanced thermal and electrical properties will improve the performance of these PCBs. Moreover, the integration of artificial intelligence and machine learning in PCB design and manufacturing will enable more intelligent and efficient processes, further optimizing the quick turn production of Single Layer Al PCBs.

Conclusion

Quick Turn Single Layer Al PCBs have become an essential tool in the electronics industry, enabling rapid prototyping, small - batch production, and accelerated innovation. Their unique combination of the advantages of single layer Al PCBs and the agility of quick turn manufacturing makes them a valuable asset for product developers, manufacturers, and researchers. While facing challenges, the market for these PCBs is set to grow, driven by emerging technologies and the increasing demand for faster time - to - market. As technology continues to evolve, Quick Turn Single Layer Al PCBs will play an even more significant role in shaping the future of electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB