-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 04. 2025, 20:05:20

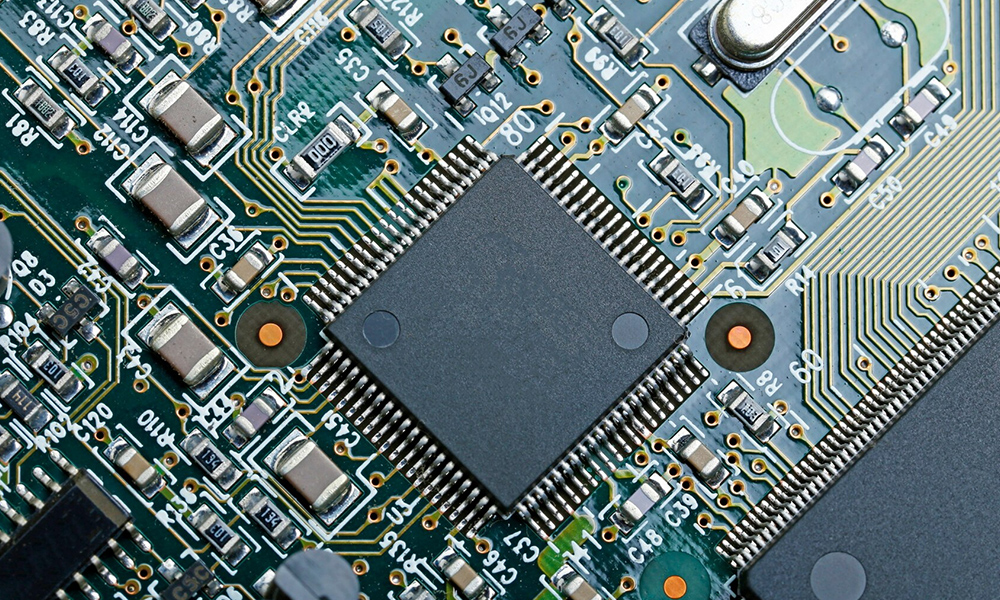

Introduction to RoHS Compliant Single Layer Metal PCB

In the ever - evolving landscape of electronics, Printed Circuit Boards (PCBs) serve as the backbone of countless devices. Among them, the RoHS compliant single layer metal PCB has emerged as a crucial component. RoHS, which stands for Restriction of Hazardous Substances, is a regulatory standard implemented by the European Union. It restricts the use of specific hazardous materials in electrical and electronic equipment, including PCBs. A single layer metal PCB, with its simple yet effective design featuring a single conductive layer on a metal substrate, has found wide - ranging applications. When this design adheres to RoHS standards, it not only meets environmental and health - safety requirements but also offers unique advantages in terms of performance and reliability.

The Significance of RoHS Compliance

Health and Environmental Protection

The primary driving force behind RoHS compliance is the protection of human health and the environment. PCBs, if not RoHS - compliant, may contain substances such as lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). These substances are known to be toxic. For example, lead can cause severe damage to the nervous system, especially in children. Mercury can lead to neurological disorders and kidney damage. When electronic devices containing such hazardous substances are discarded, they can leach these toxins into the soil and water, contaminating the environment. By mandating RoHS compliance for single layer metal PCBs, the amount of these harmful substances released into the environment is significantly reduced, safeguarding both the ecosystem and public health.

Market Accessibility

In today's global market, many regions, especially those within the European Union, have made RoHS compliance a prerequisite for the sale of electronic products. For manufacturers of devices that incorporate single layer metal PCBs, ensuring RoHS compliance is essential to access these lucrative markets. Failure to meet these standards can result in products being barred from entry, leading to significant financial losses. Moreover, as more countries around the world adopt similar environmental regulations, RoHS - compliant PCBs are becoming a global standard, opening doors to international trade for electronics manufacturers.

Design and Structure of Single Layer Metal PCBs

A single layer metal PCB consists of a metal base, which is often made of aluminum or copper - clad aluminum. This metal base serves multiple purposes. Firstly, it provides excellent thermal conductivity, allowing for efficient heat dissipation. In electronic devices where components generate heat during operation, such as power electronics or high - brightness LED lighting, the metal base of the single layer metal PCB can quickly transfer heat away from the components, preventing overheating and ensuring stable performance.

On top of the metal base is a dielectric layer. This layer is crucial as it electrically insulates the conductive traces on the top layer from the metal base. The dielectric material used must also be RoHS - compliant. Common dielectric materials include thermally conductive epoxies that not only offer electrical insulation but also aid in heat transfer.

The topmost layer of the single layer metal PCB is the conductive layer, which is typically made of copper. This layer is where the circuit traces are formed. These traces are designed to carry electrical currents, connecting various electronic components on the PCB. The simplicity of the single - layer design makes it cost - effective for certain applications where complex circuitry is not required, while still providing reliable electrical connectivity.

RoHS - Compliant Materials Used in Single Layer Metal PCBs

Conductive Materials

The copper used for the conductive traces in RoHS - compliant single layer metal PCBs must be of high purity and free from any prohibited substances. Manufacturers source copper that has been refined to meet RoHS standards. Additionally, when it comes to soldering the components to the PCB, lead - free solders are used. These solders are typically alloys of tin, silver, and copper, among other elements. They offer similar soldering properties to traditional lead - based solders but without the environmental and health risks associated with lead.

Dielectric Materials

The dielectric materials used in RoHS - compliant single layer metal PCBs are carefully selected. Thermally conductive epoxies used as dielectrics are formulated to be free from hazardous substances. These materials are tested to ensure that they do not contain any of the restricted substances under the RoHS directive. They must also maintain their electrical and thermal properties over a wide range of temperatures and operating conditions, ensuring the long - term reliability of the PCB.

Metal Base Materials

For the metal base, materials like aluminum are popular due to their good thermal conductivity, lightweight nature, and cost - effectiveness. Aluminum used in RoHS - compliant single layer metal PCBs is sourced from suppliers who can guarantee its compliance with RoHS regulations. This means that the aluminum is free from contaminants such as lead, mercury, and other restricted substances, making it suitable for use in environmentally - friendly PCBs.

Manufacturing Process of RoHS - Compliant Single Layer Metal PCBs

Material Preparation

The manufacturing process begins with the careful selection and preparation of materials. All materials, including the metal base, dielectric, and copper for the conductive layer, are sourced from suppliers that can provide documentation of RoHS compliance. The metal base is cleaned to remove any impurities on its surface, ensuring proper adhesion of the dielectric layer. The copper is also prepared, often in the form of a copper foil, which will be used to create the circuit traces.

Lamination

The dielectric layer is then laminated onto the metal base. This process involves applying heat and pressure to bond the dielectric material firmly to the metal. The temperature and pressure are carefully controlled to ensure a strong and uniform bond. After lamination, the copper foil is laminated onto the dielectric layer. Special adhesives, which are also RoHS - compliant, are used to ensure good adhesion between the copper and the dielectric.

Circuit Pattern Formation

To create the circuit pattern on the copper layer, a photolithography process is commonly used. A photoresist material, which is RoHS - compliant, is applied to the copper surface. The PCB is then exposed to ultraviolet (UV) light through a mask that has the desired circuit pattern. The exposed photoresist is removed, leaving behind the areas of copper that will form the circuit traces. The PCB is then immersed in an etching solution, which dissolves the unprotected copper, revealing the circuit pattern.

Surface Finishing

After the circuit pattern is formed, a surface finishing process is carried out. This can include applying a solder mask, which is a protective layer that prevents accidental soldering between adjacent traces and also provides some protection against environmental factors such as moisture and dust. The solder mask used is RoHS - compliant. Additionally, a final surface finish, such as an immersion gold finish, may be applied to improve the solderability and corrosion resistance of the copper traces. All materials used in this surface finishing process must adhere to RoHS standards.

Applications of RoHS - Compliant Single Layer Metal PCBs

LED Lighting

In the LED lighting industry, RoHS - compliant single layer metal PCBs are widely used. High - power LEDs generate a significant amount of heat during operation. The excellent thermal conductivity of the metal base in these PCBs allows for efficient heat dissipation, ensuring the LEDs operate at optimal temperatures. This not only extends the lifespan of the LEDs but also maintains their brightness and color accuracy. Since LED lighting products are often used in residential, commercial, and public spaces, the use of RoHS - compliant PCBs ensures that these lighting systems are safe for human use and do not pose an environmental risk.

Power Electronics

Power electronics applications, such as power supplies, inverters, and motor drivers, require PCBs that can handle high currents and dissipate heat effectively. RoHS - compliant single layer metal PCBs are well - suited for these applications. The single - layer design simplifies the circuit layout for power - related components, and the RoHS - compliant materials ensure that the PCB is safe for use in various environments. These PCBs are used in a wide range of power - related devices, from small - scale consumer electronics power adapters to large - scale industrial power conversion systems.

Automotive Electronics

The automotive industry has strict requirements for the components used in vehicles, both in terms of performance and safety. RoHS - compliant single layer metal PCBs are used in various automotive applications, such as engine control units, lighting systems, and infotainment systems. The metal base of these PCBs helps in reducing the overall weight of the vehicle, which is beneficial for fuel efficiency. The RoHS compliance ensures that in case of vehicle disposal, the PCBs do not release harmful substances into the environment.

Consumer Electronics

In consumer electronics, where devices are becoming smaller, more powerful, and environmentally friendly, RoHS - compliant single layer metal PCBs play a vital role. Devices like smartphones, tablets, and laptops may use these PCBs in certain sub - assemblies. The single - layer design can be cost - effective for less complex circuitry within these devices, and the RoHS compliance meets the growing consumer demand for products that are safe for both use and disposal.

Quality Control and Certification for RoHS - Compliant Single Layer Metal PCBs

In - Process Quality Checks

During the manufacturing process of RoHS - compliant single layer metal PCBs, multiple in - process quality checks are carried out. These checks ensure that the materials used are indeed RoHS - compliant and that the manufacturing process is not introducing any contaminants. For example, the thickness of the copper layer, the adhesion of the dielectric layer to the metal base, and the accuracy of the circuit pattern are all inspected at various stages of production.

Final Product Testing

Once the PCB is fully manufactured, it undergoes a series of final product tests. This includes electrical testing to ensure that the circuit traces are conducting electricity properly and that there are no short circuits or open circuits. Thermal testing is also performed to verify that the PCB can effectively dissipate heat. Additionally, tests are carried out to confirm that the PCB meets all RoHS requirements. This may involve using specialized equipment to detect the presence of any restricted substances in the PCB materials.

Certification

To prove RoHS compliance, PCB manufacturers obtain certification from recognized third - party testing laboratories. These laboratories conduct comprehensive tests on the PCBs, including chemical analysis to detect the presence of restricted substances. Once the PCB passes all the tests, it is issued a RoHS compliance certificate. This certificate is essential for manufacturers to demonstrate to their customers and regulatory authorities that their single layer metal PCBs meet the strict RoHS standards.

Future Trends and Developments

Advancements in Materials

As technology progresses, there will be a continuous search for even better RoHS - compliant materials for single layer metal PCBs. New dielectric materials with improved thermal conductivity and electrical properties may be developed. These materials could further enhance the performance of the PCBs, allowing for more efficient heat dissipation and better electrical insulation. Additionally, there may be advancements in the formulation of lead - free solders to improve their soldering performance and reliability.

Expanding Application Areas

With the increasing focus on environmental protection and sustainable development, the demand for RoHS - compliant products will continue to grow. This will lead to the expansion of the application areas for RoHS - compliant single layer metal PCBs. They may find use in emerging technologies such as the Internet of Things (IoT) devices, where small - sized, reliable, and environmentally friendly PCBs are required. In the field of renewable energy, these PCBs could be used in solar panel inverters and wind turbine control systems, contributing to a greener energy future.

Stricter Regulations

As awareness of environmental issues increases, regulatory bodies may introduce even stricter regulations related to the use of hazardous substances in electronics. This will drive PCB manufacturers to continuously improve their manufacturing processes and materials to stay ahead of the compliance curve. Manufacturers will need to invest in research and development to ensure that their RoHS - compliant single layer metal PCBs can meet these evolving regulatory requirements.

In conclusion, RoHS - compliant single layer metal PCBs are a significant step forward in the electronics industry. They offer a combination of environmental safety, reliable performance, and cost - effectiveness in various applications. With ongoing developments in materials, expanding application areas, and evolving regulations, these PCBs are set to play an even more crucial role in the future of electronics manufacturing.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB