-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 19. 2025, 09:16:24

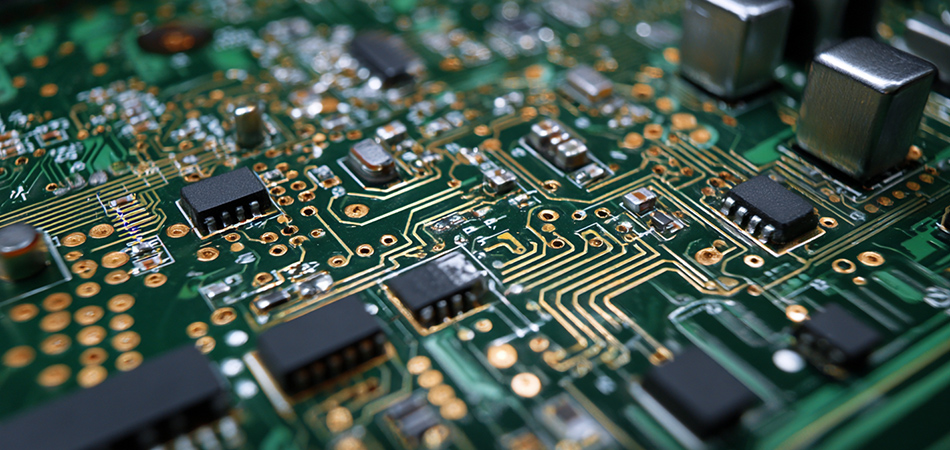

In an era where environmental consciousness and sustainable manufacturing practices are at the forefront of the electronics industry, the Restriction of Hazardous Substances (RoHS) directive has emerged as a pivotal regulatory framework. RoHS compliance ensures that electronic products, including Printed Circuit Boards (PCBs), are free from hazardous materials that can pose risks to human health and the environment. Among the various types of PCBs, Aluminum Metal PCBs have gained significant traction due to their excellent thermal management and mechanical properties. When combined with RoHS compliance, RoHS Compliant Aluminum Metal PCBs offer a unique blend of environmental friendliness and high - performance capabilities, making them a preferred choice for a wide range of applications. This article will explore the key aspects of RoHS Compliant Aluminum Metal PCBs, including their definition, benefits, design considerations, manufacturing processes, applications, market dynamics, and future trends.

Understanding RoHS Compliant Aluminum Metal PCBs

The RoHS Directive and Its Significance

The RoHS directive, initially introduced by the European Union, restricts the use of specific hazardous substances in the manufacturing of electrical and electronic equipment. These substances include lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs), and polybrominated diphenyl ethers (PBDEs). The primary objective of RoHS is to reduce the environmental impact of electronic waste by minimizing the release of toxic materials during disposal, recycling, or incineration. For the electronics industry, RoHS compliance has become not only a regulatory requirement but also a competitive advantage, as consumers and businesses increasingly prioritize environmentally friendly products.

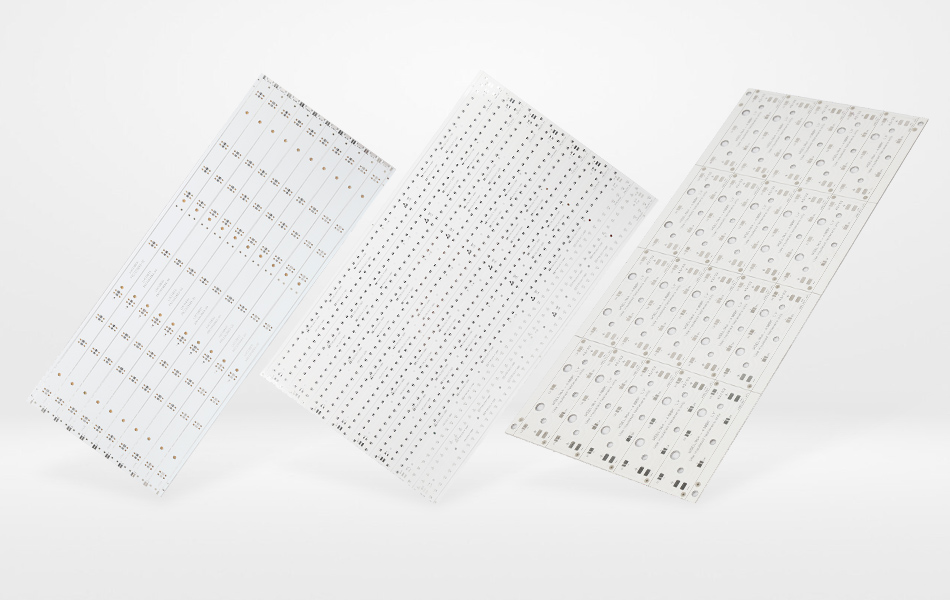

Characteristics of Aluminum Metal PCBs

Aluminum Metal PCBs are characterized by their use of an aluminum substrate as the core material. Aluminum offers several advantages that make it ideal for PCB applications. Firstly, it has high thermal conductivity, allowing for efficient heat dissipation from heat - generating components. This is crucial in applications where maintaining low operating temperatures is essential for component reliability and performance. Secondly, aluminum is lightweight, which is beneficial in industries such as aerospace and automotive, where reducing the weight of electronic components can contribute to overall energy efficiency. Additionally, aluminum has good mechanical strength, enabling the PCB to withstand mechanical stress, vibrations, and impacts.

The Synergy of RoHS Compliance and Aluminum Metal PCBs

When Aluminum Metal PCBs are manufactured to be RoHS compliant, they combine the environmental benefits of reduced hazardous substances with the inherent advantages of aluminum. This synergy results in a PCB that not only meets strict environmental regulations but also offers superior performance in terms of thermal management, mechanical durability, and electrical insulation. RoHS Compliant Aluminum Metal PCBs are thus suitable for a wide range of applications where both environmental sustainability and high - performance electronics are required.

Benefits of RoHS Compliant Aluminum Metal PCBs

Environmental Friendliness

The most significant benefit of RoHS Compliant Aluminum Metal PCBs is their reduced environmental impact. By eliminating hazardous substances, these PCBs contribute to a cleaner and safer environment during their entire lifecycle. When these PCBs reach the end of their useful life, they can be recycled more easily and safely, without the risk of releasing toxic materials into the environment. This aligns with the growing global trend towards sustainable manufacturing and waste management, making RoHS Compliant Aluminum Metal PCBs an environmentally responsible choice for electronics manufacturers.

Enhanced Thermal Performance

As mentioned earlier, the aluminum substrate in these PCBs provides excellent thermal conductivity. This allows for efficient heat transfer from components such as power transistors, LEDs, and integrated circuits to the surrounding environment. By effectively managing heat, RoHS Compliant Aluminum Metal PCBs can prevent thermal stress and overheating, which can lead to component failure and reduced device lifespan. The improved thermal performance also enables the design of more compact and powerful electronic devices, as heat - related limitations are minimized.

Mechanical Strength and Durability

The mechanical properties of aluminum contribute to the strength and durability of RoHS Compliant Aluminum Metal PCBs. These PCBs can withstand mechanical stress, vibrations, and shocks, making them suitable for applications in harsh environments. In industries such as automotive, aerospace, and industrial automation, where PCBs are often subjected to extreme conditions, the mechanical robustness of RoHS Compliant Aluminum Metal PCBs ensures reliable operation and long - term performance.

Electrical Insulation and Signal Integrity

Despite the presence of a conductive aluminum substrate, RoHS Compliant Aluminum Metal PCBs are designed to provide excellent electrical insulation. A thermally conductive dielectric layer is used to separate the aluminum from the electrical traces, ensuring that there are no electrical short - circuits. This dielectric layer also helps to maintain signal integrity, preventing electromagnetic interference (EMI) and ensuring reliable signal transmission between components.

Design Considerations for RoHS Compliant Aluminum Metal PCBs

Thermal Design

Component Placement

The strategic placement of components on a RoHS Compliant Aluminum Metal PCB is crucial for effective thermal management. Heat - generating components should be positioned in areas that allow for easy heat transfer to the aluminum substrate. For example, they can be placed near the edges of the PCB where there is better air circulation or adjacent to heat - dissipating elements such as heat sinks. Components that are sensitive to heat should be located away from heat sources to prevent thermal stress and potential damage.

Thermal Vias and Heat Sink Integration

Thermal vias play a vital role in enhancing the heat - transfer efficiency of these PCBs. These are small holes filled with a highly conductive material that connect the surface - mounted components to the aluminum substrate, creating a direct path for heat to flow. Additionally, integrating heat sinks with the PCB can further improve heat dissipation. The size, shape, and mounting method of the heat sink need to be carefully selected based on the heat - generating capacity of the components and the available space in the electronic device. Thermal interface materials should also be used to ensure a good thermal contact between the heat sink and the PCB.

Electrical Design

Trace Routing and Impedance Control

In the electrical design of RoHS Compliant Aluminum Metal PCBs, trace routing requires careful planning to ensure signal integrity. For high - speed signals, impedance - controlled traces are essential. Designers need to consider factors such as trace width, length, spacing, and the dielectric constant of the insulating layer to calculate the appropriate impedance values. The presence of the aluminum substrate can also influence the electromagnetic field around the traces, so additional considerations are needed to minimize signal reflections, crosstalk, and interference.

Power and Ground Plane Design

Power and ground planes are integral parts of the electrical design. The aluminum substrate can sometimes be utilized as a ground plane, taking advantage of its low resistance and large surface area. Well - designed power and ground planes help to distribute electrical power evenly across the PCB and provide a stable return path for electrical current. To ensure optimal performance, power and ground planes should be continuous, with minimal splits or gaps, and proper grounding techniques should be employed to reduce EMI.

Manufacturing Processes of RoHS Compliant Aluminum Metal PCBs

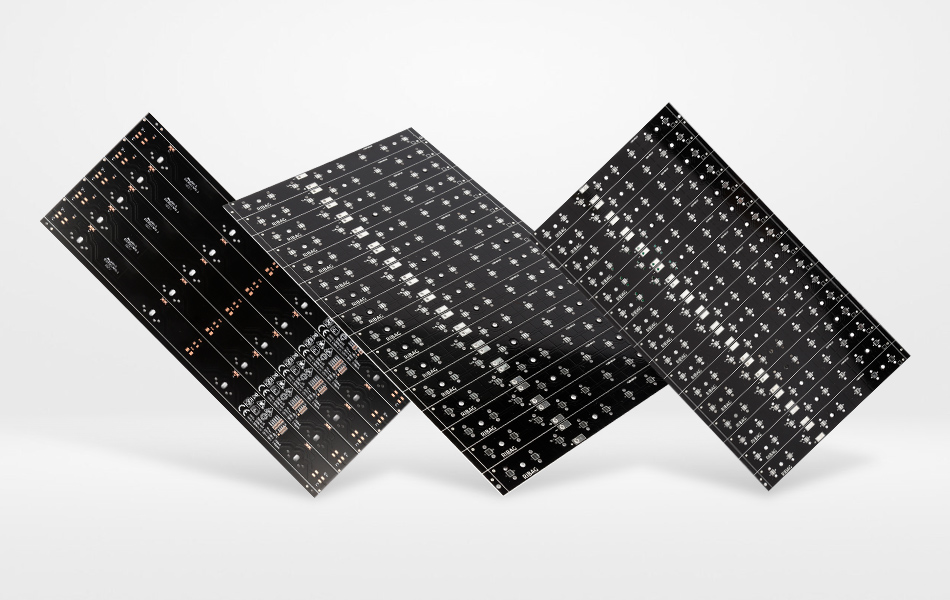

Material Selection

The manufacturing process begins with the careful selection of materials. For the aluminum substrate, high - quality aluminum with consistent thickness and purity is chosen. The thermally conductive dielectric material must meet RoHS requirements and have excellent electrical insulation properties, high thermal conductivity, and good adhesion to both the aluminum and the copper trace layer. Copper foil for the traces should also be selected based on its conductivity and compliance with RoHS standards. All materials are thoroughly inspected to ensure they are free from hazardous substances.

Lamination

Lamination is a critical step where the aluminum substrate, dielectric layer, and copper foil are bonded together. Heat and pressure are applied to cure the dielectric material, creating a strong and cohesive structure. Precise control of lamination parameters, such as temperature, pressure, and time, is essential to ensure a uniform bond and avoid defects such as voids, delaminations, or uneven bonding. Any imperfections in the lamination can affect the thermal and electrical performance of the PCB.

Drilling and Plating

After lamination, drilling is performed to create holes for vias, component mounting, and electrical connections. High - precision drilling machines are used to ensure accurate hole placement and clean hole walls. Following drilling, the holes are plated with copper to create electrical connections between the different layers of the PCB and to provide a solderable surface for component attachment. The plating process, typically electroplating, requires careful control of parameters such as current density, plating time, and temperature to achieve a uniform and thick copper deposit.

Circuit Patterning

Circuit patterning is the process of creating the electrical circuits on the copper layer. Photolithography is commonly used, where a photosensitive resist material is applied to the copper surface, and a patterned mask is used to expose the resist to ultraviolet (UV) light. The exposed areas of the resist are chemically altered and removed during the development process, leaving the unexposed resist in the shape of the circuit pattern. The remaining copper is then etched away using an etching solution, leaving only the copper traces that form the electrical circuits.

Applications of RoHS Compliant Aluminum Metal PCBs

LED Lighting

RoHS Compliant Aluminum Metal PCBs are widely used in LED lighting applications. LEDs generate a significant amount of heat during operation, and the excellent thermal management capabilities of these PCBs ensure efficient heat dissipation, which is crucial for maintaining the luminous efficiency and lifespan of the LEDs. Additionally, the environmental friendliness of RoHS - compliant PCBs makes them an ideal choice for lighting products, as they align with the growing consumer demand for sustainable and energy - efficient lighting solutions.

Automotive Electronics

In the automotive industry, where reliability, durability, and environmental compliance are essential, RoHS Compliant Aluminum Metal PCBs find extensive use. They are employed in various automotive systems, including engine control units (ECUs), advanced driver - assistance systems (ADAS), and automotive lighting. The mechanical strength of these PCBs allows them to withstand the vibrations and shocks experienced during vehicle operation, while their thermal management properties ensure the stable operation of components in the harsh under - hood environment.

Aerospace and Defense

Aerospace and defense applications often require PCBs that can perform reliably in extreme conditions. RoHS Compliant Aluminum Metal PCBs meet these requirements, offering excellent thermal management, mechanical durability, and electrical performance. They are used in aircraft avionics systems, satellite communication equipment, and military electronics, where the elimination of hazardous substances is also important for environmental and safety reasons.

Consumer Electronics

With the increasing consumer awareness of environmental issues, RoHS Compliant Aluminum Metal PCBs are also being adopted in consumer electronics products such as smartphones, tablets, laptops, and smartwatches. These PCBs enable the design of more compact and powerful devices by effectively managing heat, while also meeting the consumers' expectations for sustainable products.

Market Dynamics of RoHS Compliant Aluminum Metal PCBs

Market Growth

The global market for RoHS Compliant Aluminum Metal PCBs has been experiencing steady growth in recent years. This growth is driven by several factors, including the increasing demand for environmentally friendly electronics, the expansion of the LED lighting market, the growth of the automotive and aerospace industries, and the continuous innovation in consumer electronics. As more countries and regions adopt regulations similar to the RoHS directive, the market for RoHS - compliant PCBs is expected to expand further in the coming years.

Competitive Landscape

The market for RoHS Compliant Aluminum Metal PCBs is highly competitive, with numerous manufacturers operating globally. Key players in the market include both established PCB manufacturers and emerging companies that specialize in environmentally friendly and high - performance PCB technologies. Competition is based on factors such as product quality, performance, cost - effectiveness, technological innovation, and compliance with environmental regulations. Manufacturers are constantly investing in research and development to improve the performance of their PCBs, reduce production costs, and develop new manufacturing processes that are more environmentally friendly.

Challenges and Future Trends

Challenges

Despite the growing demand for RoHS Compliant Aluminum Metal PCBs, the industry faces several challenges. One of the main challenges is the cost. The use of RoHS - compliant materials and the implementation of additional manufacturing processes to ensure compliance can increase production costs. Additionally, as electronics continue to evolve towards smaller form factors and higher performance, the design and manufacturing of these PCBs become more complex, requiring more advanced design tools and skilled engineers. Ensuring consistent quality and reliability during mass production while maintaining RoHS compliance is also a significant challenge.

Future Trends

The future of RoHS Compliant Aluminum Metal PCBs looks promising, with several trends likely to shape the industry. Advancements in materials science are expected to lead to the development of new aluminum alloys and composite materials that offer even better thermal and mechanical properties while remaining RoHS compliant. The integration of emerging technologies, such as 5G, the Internet of Things (IoT), and artificial intelligence (AI), will drive the demand for more intelligent and connected electronic devices, increasing the need for RoHS - compliant PCBs that can support high - speed data transfer, efficient power management, and effective thermal management.

The adoption of advanced manufacturing technologies, such as additive manufacturing and automation, is also expected to revolutionize the production of these PCBs. Additive manufacturing could enable more complex and customized designs, while automation will improve production efficiency, reduce costs, and enhance quality control. Moreover, the increasing focus on circular economy principles will likely lead to the development of more sustainable manufacturing processes and recycling methods for RoHS Compliant Aluminum Metal PCBs.

Conclusion

RoHS Compliant Aluminum Metal PCBs represent a significant advancement in the electronics industry, offering a harmonious blend of environmental sustainability and high - performance capabilities. Their ability to meet strict environmental regulations while providing excellent thermal management, mechanical strength, and electrical insulation makes them suitable for a diverse range of applications. Although the industry faces challenges related to cost and manufacturing complexity, ongoing advancements in materials, manufacturing technologies, and emerging trends offer great opportunities for growth and innovation. As the demand for environmentally friendly and high - performance electronics continues to rise, RoHS Compliant Aluminum Metal PCBs will undoubtedly play an increasingly important role in shaping the future of the electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB