-

- PCB TYPE

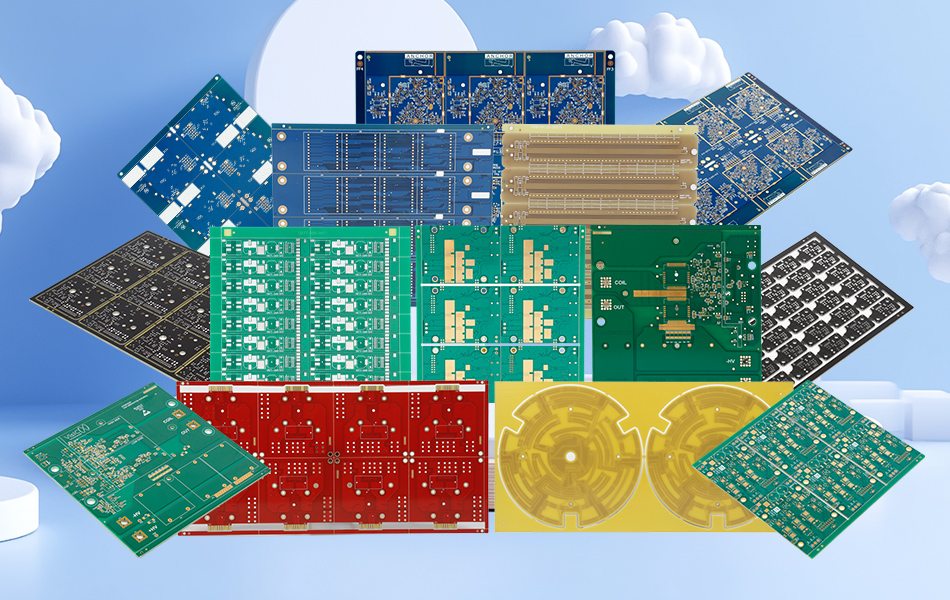

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 30. 2025, 14:57:20

In the rapidly evolving landscape of solid-state lighting, SMD LED FR4 Lighting PCB has emerged as a foundational component, enabling efficient, durable, and cost-effective illumination solutions. As a specialized printed circuit board designed to support surface-mount device (SMD) LEDs, this technology combines the mechanical stability of FR4 substrate with optimized electrical and thermal performance tailored for lighting applications. From residential fixtures to industrial lighting systems, SMD LED FR4 Lighting PCB balances design flexibility, heat management, and reliability, making it a staple in modern lighting ecosystems. This article explores the design principles, material considerations, performance attributes, and application diversity of SMD LED FR4 Lighting PCB, ensuring industry professionalism (industry expertise) and alignment with search engine optimization (SEO) best practices.

Design Fundamentals for SMD LED FR4 Lighting PCB

The effectiveness of SMD LED FR4 Lighting PCB hinges on deliberate design choices that address the unique demands of LED-based illumination:

Circuit Layout Optimization

High-Density Component Placement: SMD LEDs are arranged in configurations (linear, matrix, or custom patterns) to achieve uniform light distribution, with circuit traces routed to minimize voltage drops across the board. This ensures consistent brightness across all LEDs, preventing uneven illumination common in poorly designed layouts.

Thermal Path Design: Traces and copper planes are strategically placed to facilitate heat transfer from LED junctions to the FR4 substrate. Wider copper traces and thermal pads beneath LED packages create low-resistance pathways for heat dissipation, reducing thermal buildup that can degrade LED performance over time.

Impedance and Current Control: Circuit designs incorporate current-limiting resistors or driver integration to regulate power delivery, ensuring LEDs operate within safe current ranges. This protects against overcurrent damage and extends operational lifespans.

These design elements transform standard FR4 substrate into a specialized platform optimized for the thermal and electrical needs of SMD LED lighting.

Material Selection for Lighting Performance

FR4 Substrate Grade: High-performance FR4 variants with enhanced thermal stability are selected, with formulations prioritizing low thermal resistance and dimensional stability under temperature fluctuations. This ensures the PCB maintains structural integrity in enclosed fixtures or outdoor environments where heat accumulation is common.

Copper Cladding Specifications: Thick, high-purity copper layers (with uniform adhesion) enhance heat spreading and current carrying capacity, critical for high-brightness SMD LEDs that generate significant thermal energy during operation.

Solder Mask and Surface Finishes: Light-reflective solder masks (e.g., white or clear formulations) maximize light output by reducing absorption, while corrosion-resistant finishes (ENIG, HASL) ensure reliable solder joints between LEDs and PCB pads, even in humid or dusty environments.

Key Performance Attributes of SMD LED FR4 Lighting PCB

SMD LED FR4 Lighting PCB delivers a unique set of performance characteristics that make it indispensable in modern lighting systems:

Thermal Management Capabilities

Heat Dissipation Efficiency: While FR4 is not as thermally conductive as metal-core PCBs, optimized designs—including thermal vias, large copper planes, and strategic component spacing—enable effective heat transfer from LED junctions to the surrounding environment. This minimizes thermal degradation, a primary cause of LED lumen depreciation.

Temperature Stability: The PCB maintains stable performance across a broad operating range, from cold indoor environments to hot outdoor installations, ensuring consistent light output without color shift or flickering.

Electrical Reliability

Low Signal Loss: The FR4 substrate’s stable dielectric properties ensure minimal current leakage and voltage drop, maintaining uniform power distribution across multiple SMD LEDs. This is critical for achieving consistent brightness in linear or array configurations.

Insulation and Safety: The dielectric layer provides robust electrical insulation between copper traces and external components, preventing short circuits and ensuring compliance with safety standards for both indoor and outdoor lighting applications.

Mechanical and Environmental Durability

Structural Rigidity: FR4’s glass-fiber reinforcement resists warping, vibration, and physical stress, ensuring LED alignment remains precise in applications like automotive lighting or industrial fixtures subject to mechanical movement.

Environmental Resistance: The PCB withstands exposure to moisture, UV radiation, and chemical contaminants (e.g., in outdoor or industrial settings) when paired with protective coatings, extending fixture lifespans and reducing maintenance needs.

Application Ecosystems for SMD LED FR4 Lighting PCB

SMD LED FR4 Lighting PCB supports diverse illumination applications, adapting to varied form factors and performance requirements:

Indoor Lighting Solutions

Residential and Commercial Fixtures: Downlights, panel lights, and track lighting utilize SMD LED FR4 PCBs for their compact design and uniform light distribution. The PCB’s lightweight nature and design flexibility enable sleek, modern fixture aesthetics.

Architectural Lighting: Cove lighting, accent lighting, and decorative fixtures leverage the PCB’s ability to support custom LED layouts, creating dynamic lighting effects while maintaining energy efficiency.

Outdoor and Industrial Lighting

Street and Area Lighting: Weather-resistant SMD LED FR4 PCBs power streetlights and parking lot fixtures, with enhanced thermal designs and protective coatings ensuring reliability in extreme temperatures, rain, and dust.

Industrial and Hazardous Location Lighting: In factories, warehouses, or chemical plants, ruggedized FR4 PCBs support explosion-proof or dust-tight fixtures, with materials resistant to corrosion and high ambient temperatures.

Specialized Lighting Applications

Automotive Lighting: Interior lighting (dashboard, ambient) and exterior auxiliary lighting (fog lamps, daytime running lights) use compact SMD LED FR4 PCBs, benefiting from the material’s vibration resistance and space efficiency.

Horticultural Lighting: Custom PCB layouts support precise LED spectrum control, with FR4’s thermal stability ensuring consistent performance in grow lights where reliability directly impacts plant growth cycles.

Manufacturing and Quality Assurance for SMD LED FR4 Lighting PCB

The production of SMD LED FR4 Lighting PCB involves specialized processes to ensure performance and reliability:

Precision Manufacturing Techniques

Advanced Lamination: FR4 substrate, copper layers, and prepreg are bonded under controlled heat and pressure to eliminate voids, ensuring uniform thermal and electrical conductivity across the board.

High-Accuracy Etching: Laser or chemical etching creates fine, consistent copper traces and pad geometries, critical for accommodating small-pitch SMD LEDs and ensuring precise alignment during assembly.

Reflective Solder Mask Application: Automated processes apply light-enhancing solder masks with uniform thickness, maximizing light reflectivity while protecting copper traces from oxidation.

Rigorous Quality Validation

Thermal Performance Testing: PCBs undergo thermal imaging and thermal cycling tests to verify heat dissipation efficiency under simulated operating conditions, ensuring no hotspots compromise LED performance.

Electrical Testing: Continuity checks, insulation resistance measurements, and current flow analysis validate circuit integrity, with automated optical inspection (AOI) detecting defects like misaligned pads or trace discontinuities.

Environmental Stress Testing: Samples are exposed to humidity, temperature extremes, and vibration to simulate real-world conditions, ensuring durability in target applications from residential ceilings to outdoor poles.

Advantages Over Alternative Lighting PCB Solutions

SMD LED FR4 Lighting PCB offers distinct benefits compared to metal-core (MCPCB) or flexible PCB alternatives:

Cost-Effectiveness

Lower Material and Production Costs: FR4 substrate and manufacturing processes are mature and widely available, reducing per-unit costs compared to MCPCBs. This makes SMD LED FR4 Lighting PCB ideal for high-volume applications like residential or commercial lighting.

Design Flexibility at Scale: Standardized FR4 manufacturing supports both simple and complex designs, enabling cost-efficient production of everything from basic linear fixtures to custom-shaped architectural lighting.

Design Versatility

Compatibility with High-Density Layouts: FR4 PCBs support dense SMD LED arrays without sacrificing performance, enabling compact, high-lumen fixtures for applications like panel lights or track lighting where space is limited.

Integration Capabilities: Easily accommodates additional components (sensors, dimming controls, wireless modules) on the same board, simplifying fixture design and reducing assembly complexity.

Environmental and Regulatory Compliance

RoHS and REACH Compliance: Halogen-free FR4 variants meet global environmental standards, eliminating hazardous substances and supporting sustainable lighting solutions.

Energy Efficiency Alignment: Enables the design of low-power, high-efficiency fixtures that meet energy star ratings and carbon footprint reduction goals, critical for modern green building standards.

Future Trends and Innovations in SMD LED FR4 Lighting PCB

As LED technology advances, SMD LED FR4 Lighting PCB continues to evolve to meet emerging demands:

Material Innovations

Enhanced Thermal FR4 Formulations: Development of FR4 substrates with ceramic fillers or nano-reinforcements aims to boost thermal conductivity, bridging the performance gap with MCPCBs while maintaining cost advantages.

Sustainable Materials: Bio-based epoxy resins and recycled glass fibers are being integrated to reduce environmental impact, aligning with circular economy initiatives in lighting manufacturing.

Design and Integration Advances

Smart Lighting Integration: PCB designs increasingly incorporate sensors, Bluetooth, or Wi-Fi modules, enabling connected lighting systems with dimming, color tuning, and energy monitoring capabilities—all on a single FR4 platform.

Miniaturization and High-Density Arrays: Advanced etching and HDI (High-Density Interconnect) techniques support smaller SMD LEDs and tighter spacing, enabling higher lumen output in compact fixtures for under-cabinet, display, or portable lighting.

Application Expansion

Human-Centric Lighting: Custom FR4 PCB designs support tunable white or RGB LEDs, enabling lighting systems that adjust color temperature to enhance wellbeing in offices, schools, and healthcare facilities.

Extreme Environment Lighting: Ruggedized FR4 variants with enhanced UV and chemical resistance are expanding into marine, mining, and outdoor industrial applications, where durability is paramount.

Conclusion

SMD LED FR4 Lighting PCB represents a perfect fusion of cost-effectiveness, performance, and versatility, enabling the next generation of energy-efficient lighting solutions. By leveraging FR4’s mechanical stability and optimizing for thermal and electrical needs of SMD LEDs, this technology powers applications from residential homes to industrial facilities, delivering reliable illumination with minimal environmental impact. As material innovations and design techniques advance, SMD LED FR4 Lighting PCB will continue to play a central role in shaping the future of lighting—where efficiency, durability, and smart functionality converge to meet evolving industry and consumer demands.

Keywords: SMD LED FR4 Lighting PCB, LED lighting substrate, thermal management in LED PCBs, FR4 for lighting applications, SMD LED circuit design, high-efficiency lighting PCB, outdoor LED PCB.

This article provides a comprehensive, technically rigorous overview of SMD LED FR4 Lighting PCB, emphasizing its design principles, performance attributes, and industry relevance while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB