-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 30. 2025, 08:58:38

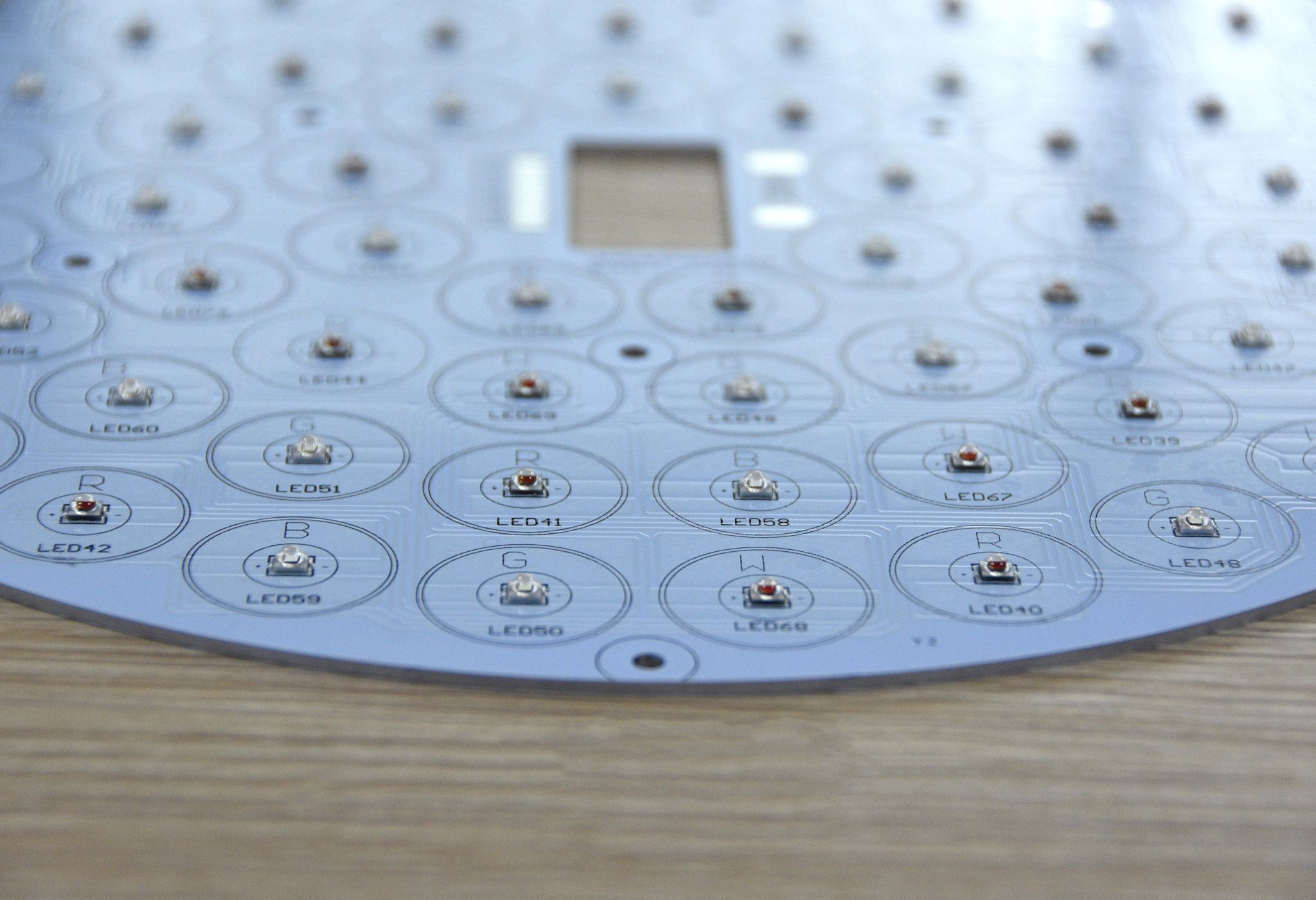

The world of LED products is vast and ever-evolving. At the heart of this innovation is Surface Mount Technology (SMT), a critical component in the manufacturing process. SMT assembly for LED products ensures that these devices are efficient, reliable, and capable of meeting diverse needs. In this article, we will explore the intricacies of SMT assembly in LED manufacturing, highlighting its benefits and key steps involved.

Surface Mount Technology, or SMT, is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). This technology is widely used in the LED manufacturing process due to its efficiency and ability to produce compact, high-performance products.

Efficiency: SMT allows for the production of smaller, more efficient LED products. The components are mounted directly onto the PCB, reducing the need for wire connections and resulting in a more streamlined manufacturing process.

Reliability: The direct mounting of components enhances the reliability of LED products. This method reduces the risk of connection failures, ensuring the longevity and durability of the products.

Cost-Effective: By minimizing the need for manual intervention, SMT reduces labor costs. Additionally, the compact nature of SMT components allows manufacturers to produce more LEDs in less space, optimizing production costs.

The SMT assembly process for LED products involves several key steps, each crucial for ensuring the quality and performance of the final product. Let's dive into the main stages of this assembly process.

The first step in SMT assembly is the application of solder paste onto the PCB. This paste acts as an adhesive that holds the components in place and provides the electrical connection needed for the circuit. The application is usually done using a stencil that aligns with the PCB layout.

Once the solder paste is applied, the next step is placing the SMT components onto the PCB. This step is typically automated using a pick-and-place machine, which accurately positions each component onto the board. Precision is vital in this step to ensure the proper functioning of the LED product.

After the components are placed, the PCB undergoes a process called reflow soldering. The board is heated in a reflow oven, causing the solder paste to melt and form a solid connection between the components and the PCB. This step is crucial as it solidifies the electrical connections, ensuring the reliability of the LED product.

Quality control is an essential aspect of SMT assembly. After reflow soldering, the PCB is inspected for any defects or misalignments. Automated optical inspection (AOI) systems are often used to detect issues such as solder bridges, misplaced components, or incomplete solder joints. Any defects identified are corrected to ensure the highest quality standards are met.

The final step in the SMT assembly process is testing the finished LED product. Functional testing is conducted to ensure that the product operates as expected and meets all performance specifications. This step is crucial for verifying the reliability and functionality of the LED products before they reach the market

.

SMT assembly offers numerous advantages in the manufacturing of LED products:

High Density: SMT allows for the placement of more components in a given area, enabling the production of smaller and more efficient LED devices.

Speed: The automated nature of SMT assembly speeds up the manufacturing process, allowing for quicker turnaround times and increased production capacity.

Flexibility: SMT can accommodate a wide range of component sizes and types, making it suitable for various LED applications.

Reduced Weight: The compact design of SMT components results in lighter LED products, which is beneficial for applications where weight is a concern.

While SMT offers many benefits, it also presents certain challenges that manufacturers must address:

Component Handling: The small size of SMT components can make them difficult to handle and place accurately, requiring precise equipment and skilled operators.

Thermal Management: LEDs generate heat, and managing this heat is critical to prevent damage to the components and ensure the longevity of the product.

Material Compatibility: Ensuring that the materials used in the assembly process are compatible with the SMT method is crucial for achieving optimal results.

In the ever-growing world of LED technology, SMT assembly plays a pivotal role in producing high-quality, efficient, and reliable products. By understanding the key steps involved in SMT assembly and addressing the associated challenges, manufacturers can optimize their processes and deliver superior LED products to the market.

Embracing SMT in LED manufacturing not only enhances the performance and reliability of the products but also offers cost and efficiency benefits, making it an essential component of the modern electronics industry.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB