-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 26. 2025, 12:50:05

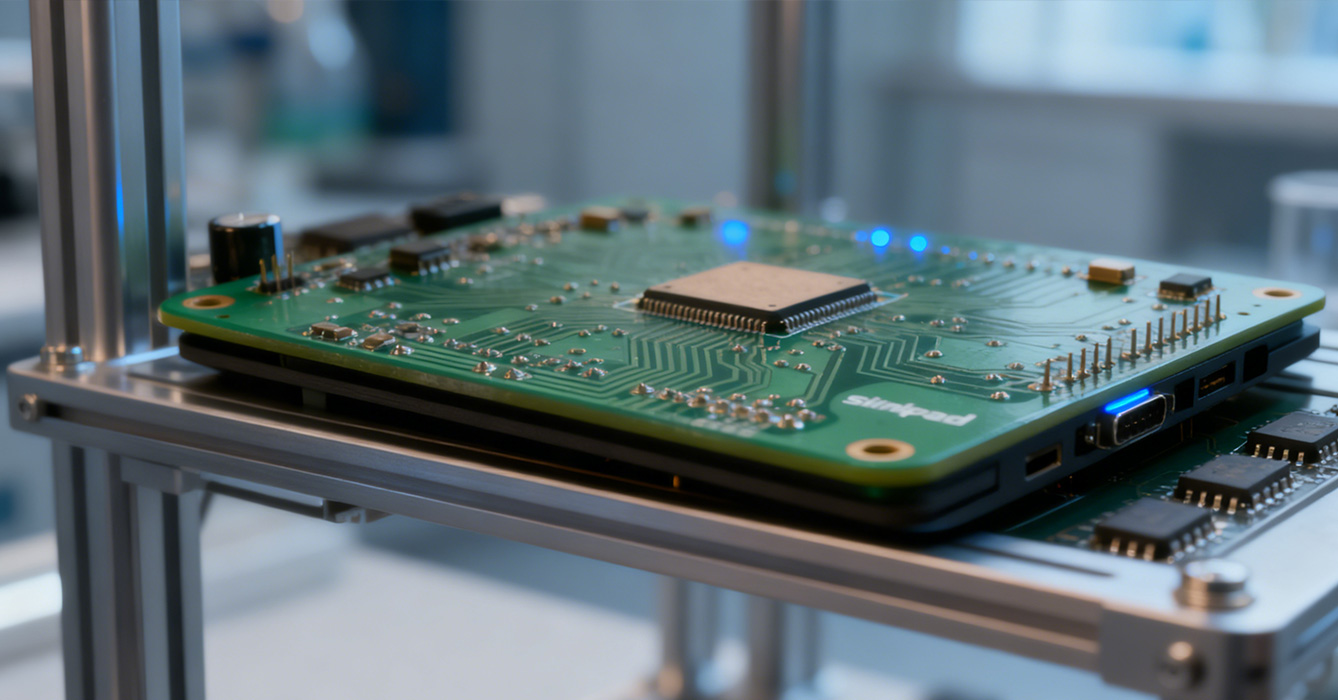

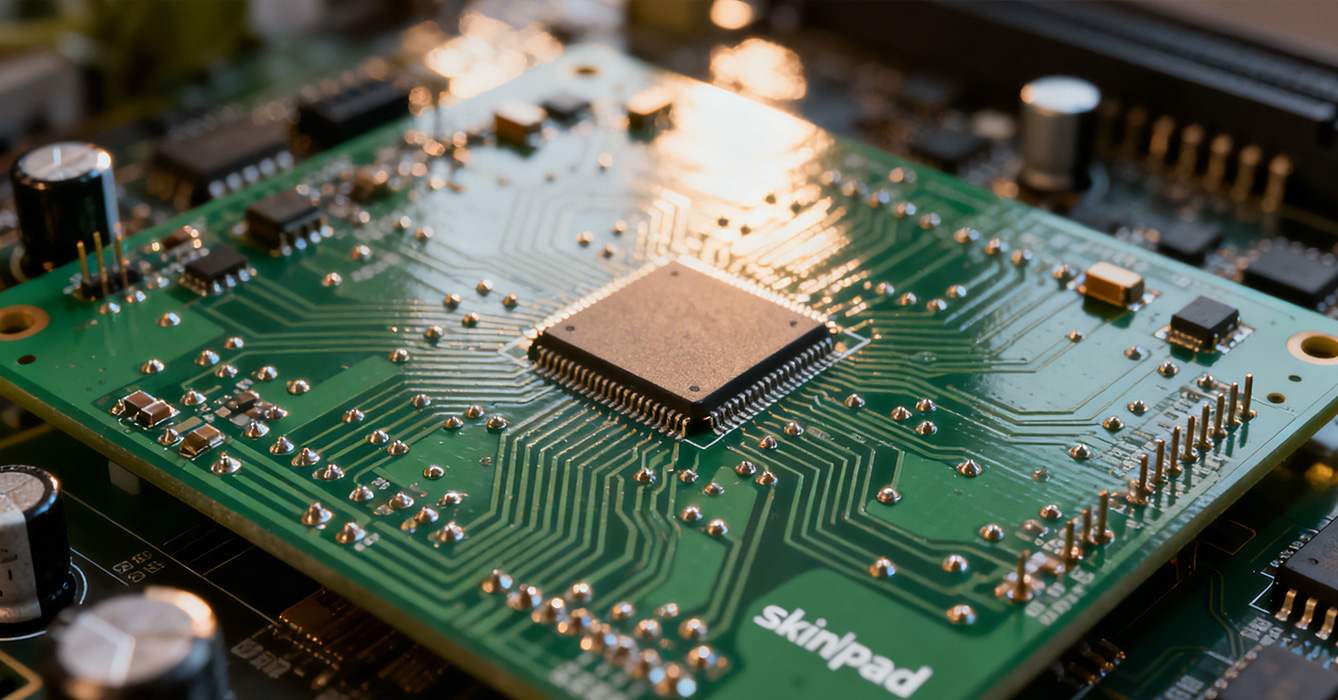

In the age of power-dense electronics, where devices are expected to deliver more performance in smaller footprints, thermal management has become a universal challenge. Sinkpad PCB stands out as a versatile solution, engineered to address heat dissipation and structural reliability across industrial, commercial, consumer, and specialized applications. Unlike generic PCBs that require external cooling add-ons, Sinkpad PCB integrates dedicated thermal sink structures directly into its design—unifying electrical functionality, thermal efficiency, and mechanical stability. This all-in-one approach makes it a cornerstone component for high-power systems, from industrial machinery to smart lighting and medical devices, proving its value far beyond automotive use cases.

At the core of Sinkpad PCB’s appeal is its ability to solve two interconnected problems: inefficient heat transfer and structural fragility in high-power electronics. Traditional PCBs often rely on adhesive thermal pads or external heat sinks, which add complexity, size, and potential points of failure. Sinkpad PCB eliminates these drawbacks by embedding thermal sink regions directly into the board’s substrate. These sinks create a direct thermal path from heat-generating components—such as power semiconductors, LED arrays, and motor drivers—to the PCB itself, rapidly distributing heat to prevent hotspots. Concurrently, the sinkpad structure reinforces the PCB’s rigidity, resisting warpage and mechanical stress caused by thermal cycling or operational vibration. This dual benefit ensures consistent performance across diverse environments, from temperature-controlled data centers to rugged industrial floors.

Across sectors, high-power electronics share common pain points that Sinkpad PCB is uniquely positioned to resolve:

Concentrated Heat Buildup: Components like high-wattage LEDs, IGBTs, and power modules generate intense localized heat. Sinkpad PCB’s targeted thermal management eliminates the risk of overheating, which degrades performance and shortens component lifespans.

Space Constraints: Modern devices—from compact industrial sensors to slim commercial lighting fixtures—require high performance in limited space. Sinkpad PCB’s integrated design removes the need for bulky external heat sinks, supporting miniaturization without compromising power handling.

Reliability Under Stress: Whether exposed to industrial vibration, frequent thermal cycling in consumer electronics, or sterile environments in medical devices, Sinkpad PCB’s robust construction ensures long-term durability. Its reinforced structure resists solder joint failure and substrate degradation, reducing maintenance costs and downtime.

Design Flexibility: Sinkpad PCB adapts to diverse circuit layouts, allowing engineers to place high-power components and sensitive signal circuits on the same board. The separation of thermal and electrical pathways eliminates interference, enabling more complex, multifunctional designs.

Sinkpad PCB’s adaptability makes it indispensable across a wide range of high-power electronics:

Industrial Electronics: Powers motor drives, power inverters, and automation controllers in manufacturing facilities. Its ability to withstand harsh temperatures and vibration ensures reliable operation in assembly lines, robotics, and industrial IoT (IIoT) systems.

Commercial & Smart Lighting: Enables high-brightness LED fixtures for retail spaces, warehouses, and outdoor infrastructure. Sinkpad PCB’s thermal efficiency supports dense LED arrays, maintaining lumen output and extending fixture lifespans while enabling compact, aesthetically pleasing designs.

Medical Devices: Critical for equipment like laser therapy tools, diagnostic scanners, and surgical instruments. Its stable thermal performance ensures precision in temperature-sensitive procedures, while its structural reliability meets strict medical device safety standards.

Consumer Electronics: Powers high-performance chargers, gaming consoles, and portable power banks. Sinkpad PCB’s compact thermal management allows for sleeker device designs without sacrificing charging speed or runtime.

Renewable Energy Systems: Supports solar inverters and wind turbine power controllers, managing heat from high-voltage components in outdoor, weather-exposed environments to ensure efficient energy conversion.

As technology evolves toward higher power densities and smarter, more connected devices, the demand for flexible thermal management solutions continues to grow. Sinkpad PCB enables this innovation by providing engineers with a blank canvas to design more efficient, compact, and reliable products. In industrial settings, it supports the shift toward automation by ensuring ruggedness in IIoT devices. In commercial lighting, it accelerates the adoption of energy-efficient LED systems by solving heat-related performance issues. For consumer electronics, it empowers the development of smaller, more powerful devices that align with modern user preferences. Across all sectors, Sinkpad PCB acts as a catalyst for progress, turning thermal management from a constraint into an enabler of innovation.

In conclusion, Sinkpad PCB is far more than a specialized automotive component—it is a universal solution for high-power electronics across industries. Its integrated thermal and mechanical design addresses shared challenges of heat dissipation, space constraints, and reliability, making it indispensable in industrial, commercial, medical, and consumer applications. As electronics continue to push the boundaries of power and miniaturization, Sinkpad PCB will remain a critical technology, enabling safer, more efficient, and more versatile devices. For engineers and manufacturers seeking a competitive edge, Sinkpad PCB is the strategic choice to overcome thermal barriers and deliver exceptional product performance.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB