-

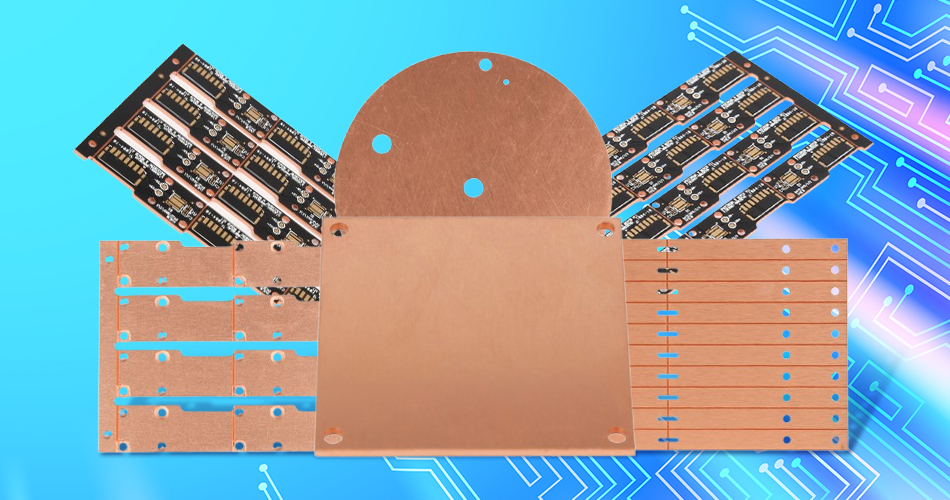

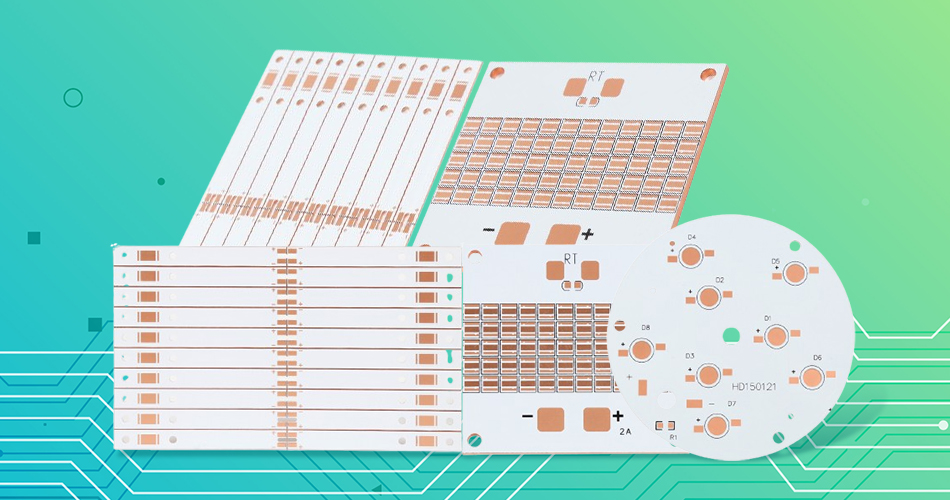

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Nov 19. 2025, 12:10:57

Sinkpad PCB is a specialized high-performance PCB variant engineered for extreme thermal and electrical loads, integrating optimized sinkpad structures with advanced copper-based cores (pure copper, diamond/copper composites, or copper-aluminum hybrids). Unlike conventional PCBs that prioritize signal routing alone, sinkpad PCBs balance three core objectives: efficient heat dissipation from high-power components (e.g., IGBTs, GaN devices), reliable high-current transmission, and maintenance of signal integrity (SI) & electromagnetic compatibility (EMC). Widely adopted in electric vehicles (EVs), 5G/6G infrastructure, and industrial power electronics, sinkpad PCBs resolve the bottleneck of power density growth in compact electronic systems. This article systematically explores sinkpad PCB’s architectural design, key design rules, manufacturing standards, industry compliance, and scenario-specific optimizations, providing a comprehensive engineering guide for high-power PCB development.

The performance of sinkpad PCB is fundamentally determined by its layer stack architecture, which must synergize thermal conductivity, mechanical stability, and signal performance.

Even-Layer Configuration: Following PCB design best practices , sinkpad PCBs adopt even-layer stacks (4/6/8 layers) to eliminate warpage caused by asymmetric thermal stress. A typical 6-layer sinkpad PCB structure is:

Top Signal Layer (1oz copper): Component mounting + low-power signal routing

Power Plane (2oz copper): High-current power distribution, adjacent to ground plane for decoupling

Sinkpad Copper Core Layer (3-4oz copper/composite): Dedicated thermal path + high-current conduction

Ground Plane (2oz copper): Low-impedance return path, tightly coupled with power plane (dielectric thickness <0.2mm)

Inner Signal Layer (1oz copper): High-speed signal routing (e.g., CAN bus, Ethernet)

Bottom Signal Layer (1oz copper): Auxiliary component mounting + thermal relief pads

Symmetric Thermal Balance: The sinkpad copper core is centered in the layer stack, with equal-thickness dielectric layers (e.g., FR-4, polyimide) on both sides to counteract thermal expansion mismatch during lamination . For diamond/copper composite cores (CTE <10 ppm/K), dielectric materials with matched CTE (e.g., ceramic-filled FR-4) are selected to minimize delamination risk.

Solid Plane for Heat Spreading: The ground plane directly beneath the sinkpad core is designed as a solid copper sheet (no segmentation) to maximize heat diffusion, while the adjacent power plane uses partial segmentation only for multi-voltage domains . This configuration reduces thermal resistance by 25-30% compared to split ground planes.

Decoupling Capacitor Integration: High-frequency decoupling capacitors (X7R/X5R ceramic) are placed within 3mm of the sinkpad’s component pins, with shortest possible traces (≤5mm) to the power/ground planes . Multiple vias (≥4) connect the capacitor pads to the planes, ensuring low-impedance power delivery and suppressing voltage ripple in high-current scenarios.

Thermal Isolation Zones: A 0.5-1mm dielectric buffer zone is reserved around the sinkpad core to isolate signal traces from thermal stress . High-speed signals (e.g., 5G RF signals) are routed away from this zone to avoid SI degradation caused by thermal-induced dielectric property changes.

Blind/Buried Via Placement: Blind vias (diameter 0.15-0.2mm) connect signal layers without penetrating the sinkpad core, while resin-filled vias reinforce mechanical stability and prevent solder wicking . Vias are spaced ≥20mil from sinkpad edges to avoid damaging the thermal path.

Sinkpad PCB’s high-power characteristics demand specialized design rules beyond standard PCB guidelines, addressing thermal management, high-current handling, and mechanical reliability.

Line Width Performance: At 25℃ with a 10℃ temperature rise, conventional PCBs using standard 1oz copper achieve a current-carrying capacity of 2A per 1mm line width. In contrast, sinkpad PCBs with 3oz thick copper cores boost this capacity to 5A per 1mm line width. The design rationale lies in the thicker copper layers (3-4oz) which reduce electrical resistance, enabling significantly higher current density in high-power applications.

Via Current Rating: A single PTH via in conventional PCBs typically handles 0.8A, while sinkpad PCBs employ 4 parallel PTH vias to achieve a 5A current rating. For ultra-high-current paths (300A+), via diameters are specified at ≥0.6mm to mitigate current crowding and prevent overheating at via junctions.

Power Trace Configuration: Conventional PCBs rely on single discrete traces for power delivery, whereas sinkpad PCBs combine wide traces with adjacent copper pour. This configuration increases the effective cross-sectional area for current flow, reducing resistive heating and improving thermal dissipation from power paths.

Copper Pour Strategy: Sinkpad regions use solid copper pour (no solder mask) to enhance heat dissipation, while non-sinkpad areas adopt 25mil×25mil grid copper pour to balance mechanical stability and heat spreading . Grid pour avoids blistering during wave soldering caused by uneven thermal expansion.

Thermal Relief Pads: Component pads connected to the sinkpad core use thermal relief patterns (4-6 spokes) to control solder wicking, ensuring sufficient solder joint strength while maintaining thermal conductivity.

Heat Sink Integration: Sinkpad PCB top/bottom layers reserve 5mm×5mm mounting pads for heat sinks, with thermal vias (density ≥10 vias/cm²) connecting the pads to the copper core for direct heat transfer.

Board Edge Clearance: Sinkpad copper core edges are spaced ≥5mm from PCB board edges, with 10mm clearance from conveyor edges (for SMT assembly) . Auxiliary edges are added if clearance requirements are not met.

Stress Relief Features: Sinkpad core corners are rounded (radius ≥1mm) to avoid stress concentration, and curved signal traces (instead of right angles) are used near the core to absorb thermal cycling stress (-40°C to 125°C).

Substrate Material Selection: For automotive/industrial applications, high-temperature substrates (e.g., Rogers 4003C, polyimide) or engineered polymer films (PC/TPU ) are used, with glass transition temperature (Tg) ≥170°C to withstand extreme operating conditions.

Sinkpad PCB manufacturing adheres to strict industry standards to ensure consistency, reliability, and performance, integrating specialized processes for thick copper and sinkpad structures.

IPC-2221: Defines general design requirements for sinkpad PCB, including copper thickness tolerance (±10% for 3oz copper), dielectric layer thickness (0.1-0.2mm for power/ground planes), and minimum trace spacing (≥8mil for 3oz copper) .

IPC-4101: Specifies substrate material requirements, such as thermal conductivity ≥1.5 W/(m·K) for FR-4 variants used in sinkpad PCBs, and moisture absorption ≤0.2% (24h/105°C).

Automotive Grade Compliance: For EV applications, sinkpad PCBs meet AEC-Q200 (passive component reliability standard), including 1000 thermal cycles (-40°C to 125°C) and 2000h humidity testing (85°C/85% RH).

Precision Lamination: Vacuum lamination with controlled temperature ramps (2°C/min) is used to bond thick copper layers and dielectric substrates, achieving >99% bonding coverage and avoiding voids . For diamond/copper composite cores, low-temperature lamination (<200°C) preserves composite material properties.

Selective Plating: Sinkpad surfaces are plated with ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) coating (Ni: 5μm, Pd: 0.1μm, Au: 0.05μm) to enhance solderability and corrosion resistance, complying with RoHS standards .

Post-Fabrication Inspection:

X-ray CT inspection detects internal voids (>5μm) in the copper-dielectric interface .

Laser flash analysis (LFA) verifies thermal conductivity of the sinkpad core (±5% accuracy).

Vibration testing (10-2000Hz, 10g acceleration) validates mechanical robustness for industrial/automotive use.

Localized Thick Copper: Only sinkpad regions use 3-4oz thick copper; other areas adopt 1oz copper to reduce material costs by 15-20%.

Standardized Layer Stacks: Reusing validated 4/6-layer stack designs across product lines reduces engineering and manufacturing lead times.

Eco-Friendly Processes: Water-based etching and recycled copper cores (99.85% purity) lower environmental impact while complying with EU REACH regulations .

Sinkpad PCB design is tailored to application-specific requirements, balancing thermal performance, size, weight, and cost across industries.

Layer Stack: 6-layer design (Signal/Power/Sinkpad Core/Ground/Signal/Signal) with 4oz copper core for traction inverters (400A current).

Key Optimizations:

Wide power traces (≥5mm) with parallel vias (8×0.8mm) to handle 350A fast-charging currents.

AEC-Q200 compliant substrate (Tg ≥180°C) to withstand under-hood temperatures (-40°C to 125°C).

Integrated thermal vias (1mm pitch) connecting IGBT pads to the sinkpad core, reducing junction temperature by 35°C.

Layer Stack: 4-layer design (Signal/Sinkpad Core/Ground/Signal) with copper-aluminum hybrid core (weight reduction 30%).

Key Optimizations:

Low-loss dielectric (e.g., Rogers 5880, Dk=2.2) for RF signal layers to maintain impedance matching (50Ω).

Sinkpad core sized to 1.5× the RF transistor footprint for targeted heat dissipation (50W module).

Minimal trace length (<10mm) for high-frequency signals to reduce insertion loss.

Layer Stack: 8-layer design (Signal/Power/Power/Sinkpad Core/Ground/Ground/Signal/Signal) for multi-voltage domains.

Key Optimizations:

Split power planes (24V/48V) with 0.3mm dielectric isolation to prevent cross-talk.

Grid copper pour (20mil×20mil) on outer layers for enhanced heat dissipation in 24/7 operating environments.

Reinforced mounting holes (diameter ≥3mm) with solder mask open the window to withstand vibration (10g acceleration).

The evolution of sinkpad PCB is driven by the growing demand for higher power density, miniaturization, and sustainability, with three key trends emerging:

Generative Layer Stack Design: AI algorithms (e.g., ANSYS Sherlock) optimize layer configurations based on thermal, electrical, and mechanical requirements, reducing design cycles by 40% while improving thermal performance by 15%.

Digital Twin Simulation: Virtual replicas of sinkpad PCBs simulate real-world operating conditions (temperature, vibration, current load) to predict failures, reducing prototyping iterations from 3 to 1.

Flexible Sinkpad PCBs: Using TPU/PC composite substrates , flexible sinkpad PCBs enable conformal mounting in curved spaces (e.g., EV battery packs), with thermal conductivity retained at >300 W/(m·K) via copper-polyimide hybrid cores.

Ceramic-Copper Hybrids: Alumina (Al₂O₃) ceramic substrates integrated with copper sinkpads offer thermal conductivity >400 W/(m·K) and CTE matching with semiconductors (Si/GaN), targeting 6G and quantum computing applications.

Recyclable Sinkpad Structures: Thermoelectric separation design enables 95% copper recovery from end-of-life PCBs, while eco-friendly dielectrics (bio-based resins) reduce carbon footprint by 30%.

Energy-Efficient Processes: Laser etching replaces chemical etching for thick copper layers, reducing water usage by 60% and eliminating hazardous waste.

Sinkpad PCB represents a paradigm shift in high-power electronic design, integrating advanced copper core technology with systematic PCB architecture optimization to address the dual challenges of thermal management and high-current transmission. By adhering to symmetric layer stacking, specialized routing rules, and industry standards (IPC, AEC-Q200), sinkpad PCBs deliver unmatched reliability in extreme operating environments—from EV powertrains to 5G base stations. The synergy of material innovations (diamond/copper composites, flexible substrates), AI-driven design tools, and sustainable manufacturing processes will continue to push the boundaries of power density and efficiency. As electronic systems evolve toward miniaturization and electrification, sinkpad PCB will remain a critical enabler, bridging the gap between performance requirements and engineering feasibility in high-power electronics.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB