-

- PCB TYPE

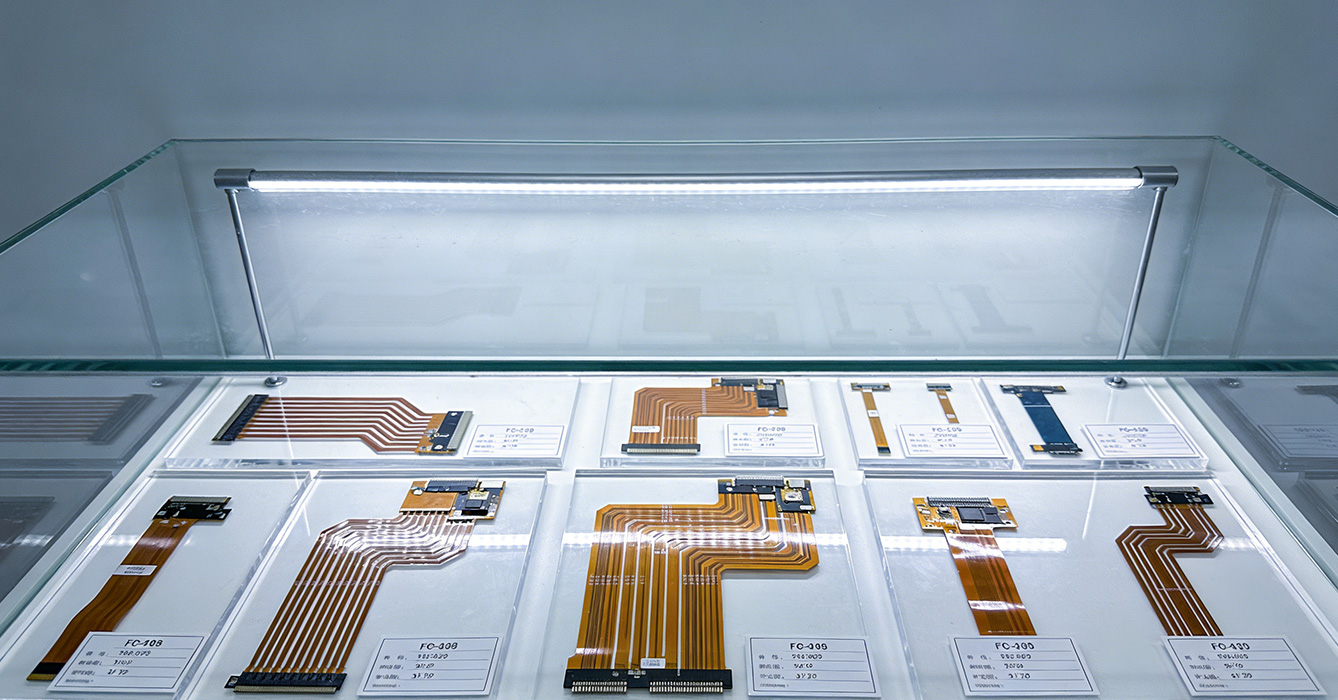

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Dec 05. 2025, 12:42:33

As smartphones continue to evolve with advanced features such as 5G connectivity, AI computing, high-resolution imaging, and fast charging, a professional smartphone FPC manufacturer has become a critical catalyst for translating these technological advancements into practical, user-centric devices. Specializing in flexible printed circuits (FPCs) tailored to the unique functional and design demands of smartphones, these manufacturers are not just component suppliers—they are technology partners that proactively iterate FPC solutions to match the rapid pace of mobile innovation. Unlike general FPC manufacturers, a smartphone-focused FPC manufacturer deeply understands the intricate balance between functional integration, power efficiency, and form factor optimization required by modern smartphones. For mobile brands striving to maintain competitiveness in a fast-changing market, partnering with a capable smartphone FPC manufacturer is essential to accelerating product development and delivering superior device performance.

The core competitiveness of a leading smartphone FPC manufacturer lies in its ability to drive technological iterations of FPCs to keep pace with the continuous functional upgrades of smartphones:

- High-Frequency Performance Optimization: With the widespread adoption of 5G and the emergence of 5.5G technologies, smartphones demand FPCs with excellent high-frequency signal integrity. Smartphone FPC manufacturers respond by developing FPCs using low-loss substrate materials and advanced shielding technologies, minimizing signal attenuation and electromagnetic interference (EMI). These optimized FPCs ensure stable 5G data transmission, supporting high-speed downloads and low-latency connectivity critical for mobile gaming and cloud services.

- Power Efficiency Enhancement: As smartphones integrate more power-hungry features (e.g., fast charging, high-brightness displays, AI processors), FPCs play a key role in power distribution efficiency. Manufacturers design low-resistance FPCs with optimized circuit routing and high-conductivity materials, reducing power loss during transmission. They also integrate thermal management solutions into FPC designs to dissipate heat generated by fast charging and high-performance computing, preventing overheating and ensuring device stability.

- Multi-Sensor Integration Support: Modern smartphones rely on a dense array of sensors (e.g., biometric sensors, environmental sensors, motion sensors) to enable intelligent features. Smartphone FPC manufacturers develop high-density FPC solutions that can seamlessly connect multiple sensors to the mainboard, leveraging ultra-fine circuit patterns and modular design. This integration ensures accurate and real-time data transmission between sensors and the device’s processing unit, supporting functions like facial recognition, gesture control, and health monitoring.

The smartphone industry is characterized by short product cycles and rapidly changing market demands, requiring smartphone FPC manufacturers to have a highly efficient market response mechanism:

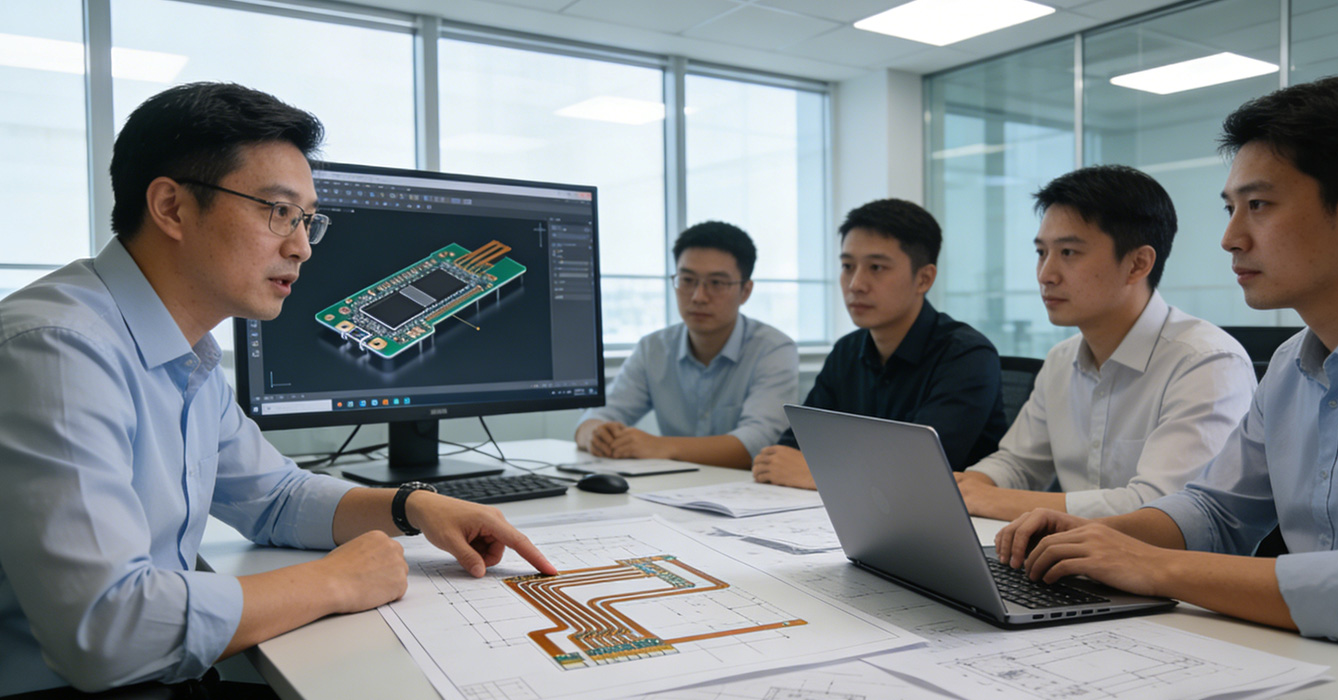

- Rapid Customization Capability: Leading manufacturers establish flexible production lines and professional engineering teams to provide rapid customization services. They can quickly adjust FPC designs according to the specific requirements of different smartphone models (e.g., flagship vs. mid-range, standard vs. foldable derivatives), including circuit layout, material selection, and form factor adaptation. This rapid customization capability helps mobile brands shorten the time from design to mass production.

- Pre-emptive Technology Layout: Instead of passively responding to customer needs, forward-looking smartphone FPC manufacturers conduct pre-emptive research and development based on industry trends. They closely track emerging technologies such as under-display cameras, solid-state batteries, and AR/VR integration, and develop corresponding FPC solutions in advance. This proactive layout enables manufacturers to provide technical support for mobile brands’ innovative product plans in a timely manner.

- Global Supply Chain Coordination: To meet the global production and supply needs of smartphone brands, manufacturers build a global supply chain network with reliable material suppliers and logistics partners. They implement strict supply chain management to ensure the stable supply of high-quality raw materials (e.g., substrates, conductive materials) and timely delivery of FPC products to manufacturing bases around the world, even amid global supply chain fluctuations.

Smartphones are used in a wide range of environments, from extreme temperatures to high-humidity conditions, requiring FPCs to have robust reliability. Smartphone FPC manufacturers implement full-scenario quality assurance systems to ensure product durability:

- Multi-Environment Reliability Testing: Manufacturers conduct rigorous testing to simulate various real-world usage scenarios, including thermal cycling testing (to adapt to -40°C to 85°C temperature changes), humidity resistance testing, drop and vibration testing, and corrosion resistance testing. These tests verify that FPCs can maintain stable performance in harsh environments, reducing the risk of device failure due to environmental factors.

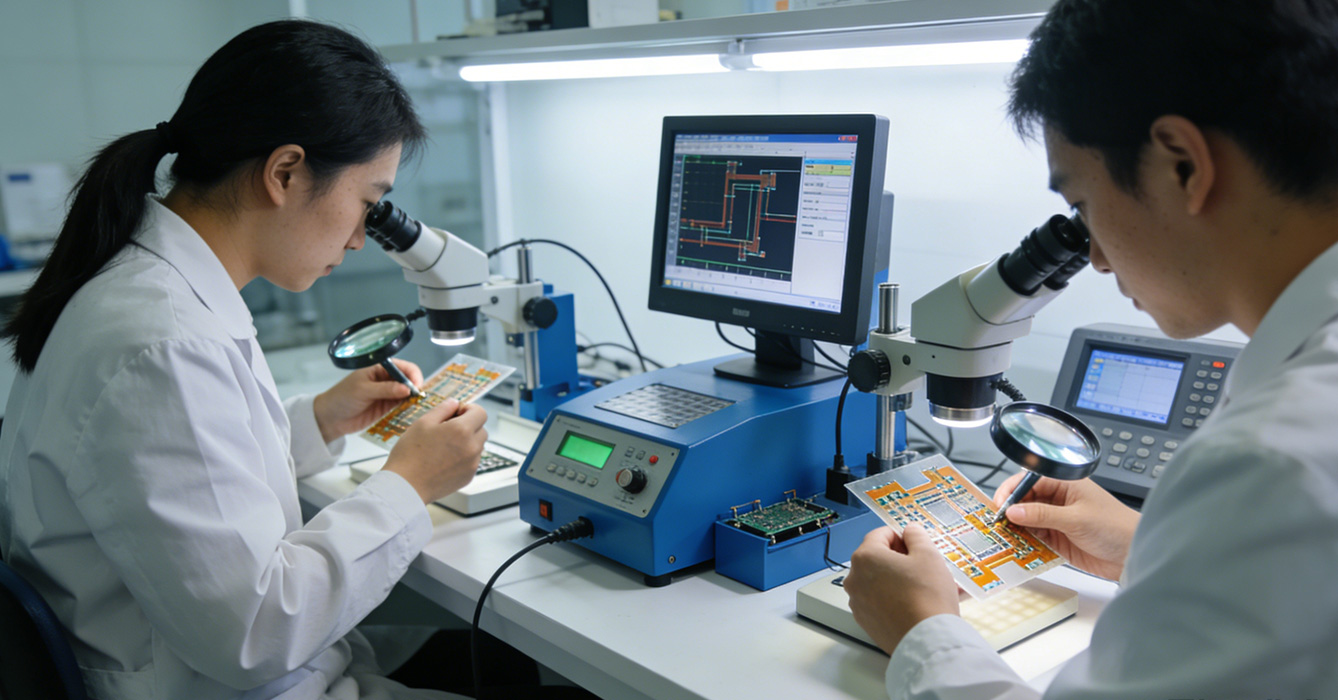

- Strict Production Quality Control: From raw material incoming inspection to final product delivery, manufacturers implement a full-process quality control system. They adopt advanced inspection technologies such as 3D automated optical inspection (AOI) and X-ray testing to detect micro-defects in FPCs (e.g., micro-cracks, poor soldering) that may affect performance. Strict batch traceability ensures that any quality issues can be quickly located and resolved.

- Compliance with Global Standards: To enter global smartphone markets, manufacturers comply with a series of international standards and certifications, including IPC-6012/2221 (for FPC quality), RoHS/REACH (for environmental protection), and ISO 9001 (for quality management). They also meet the specific quality requirements of major smartphone brands, ensuring that FPCs meet the high reliability standards of consumer electronic products.

Forward-looking smartphone FPC manufacturers are committed to sustainable innovation, driving the development of environmentally friendly and high-performance FPC solutions for the future mobile electronics industry:

- Eco-Friendly Material Application: They actively adopt recyclable and low-environmental-impact materials, such as bio-based polyimides and water-based adhesives, reducing the environmental footprint of FPC production. They also optimize production processes to minimize waste generation and energy consumption, supporting smartphone brands’ carbon neutrality goals.

- Integration with Emerging Mobile Trends: As smartphones evolve toward smarter, more connected devices (e.g., IoT-enabled mobile hubs, AR glasses companions), manufacturers are developing FPC solutions that support these emerging trends. This includes ultra-compact FPCs for wearable accessories connected to smartphones and high-bandwidth FPCs for seamless data synchronization between multiple devices.

In conclusion, a professional smartphone FPC manufacturer is a key driver of smartphone technology evolution, enabling the continuous upgrading of mobile device functions and user experiences through proactive tech iteration, efficient market response, and robust quality assurance. As the smartphone industry continues to pursue innovation in connectivity, intelligence, and sustainability, the role of smartphone FPC manufacturers in bridging technological gaps and supporting brand competitiveness will become increasingly prominent. For mobile brands aiming to lead the market, partnering with a forward-thinking smartphone FPC manufacturer is a strategic investment in long-term innovation and success.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB