-

- PCB TYPE

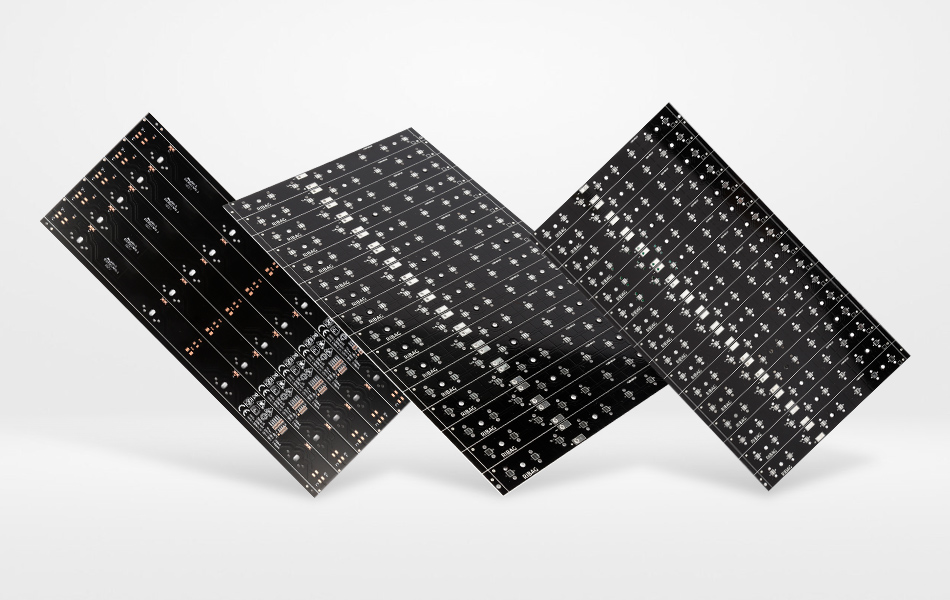

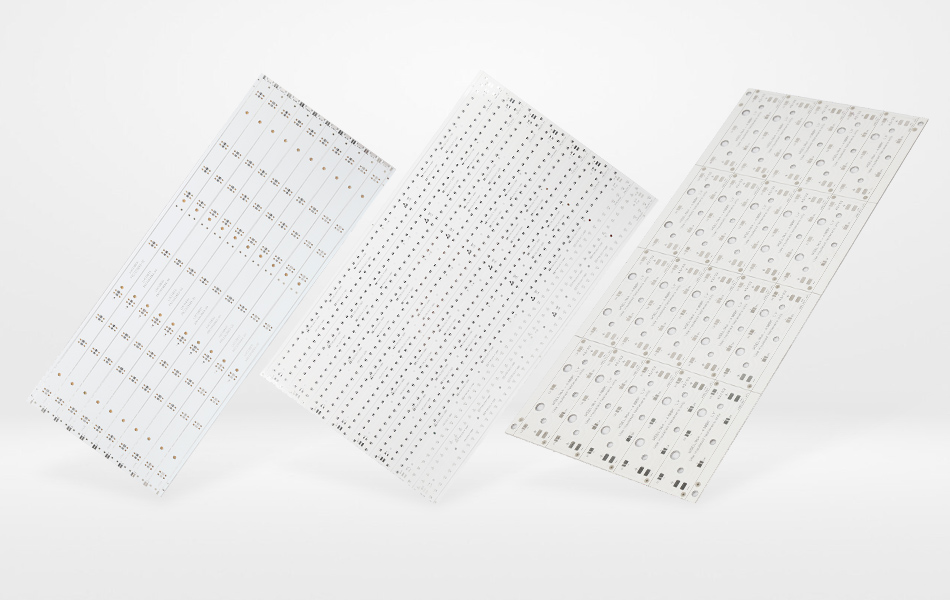

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jun 27. 2025, 08:12:33

In the ever - advancing landscape of electronic manufacturing, Aluminum Circuit Boards (ACBs) have established themselves as a cornerstone for high - performance applications, thanks to their exceptional thermal management and mechanical resilience. Among the array of features that optimize their functionality, tapped counterbore holes stand out as a critical element. A tapped counterbore hole combines the design of a counterbore— a recessed hole with a larger diameter at the top— with internal threading, enabling direct screw attachment without additional nuts. This article delves into the technical nuances of tapped counterbore holes in aluminum circuit boards, exploring their design principles, manufacturing processes, quality control measures, industry applications, and emerging trends.

Technical Fundamentals of Tapped Counterbore Holes

Definition and Core Functions

A tapped counterbore hole in an aluminum circuit board is a specialized hole consisting of two distinct sections: a larger - diameter upper recess (the counterbore) and a smaller - diameter lower hole that is internally threaded. This design serves dual purposes: it allows the head of a flat - head screw to sit flush with the board's surface, minimizing protrusion and optimizing space, while the internal threads in the lower hole provide a secure mechanical connection without requiring a nut. This configuration is particularly valuable in applications where space is constrained, vibrations are prevalent, or a clean surface finish is essential.

The tapped counterbore design distributes clamping forces evenly across the board, reducing stress concentrations that could lead to cracks or component failure. Additionally, in scenarios where the screw itself acts as an electrical conductor— such as grounding applications— the tapped counterbore ensures a stable, low - resistance connection, enhancing both mechanical and electrical reliability.

Design Differentiation from Standard Counterbores

Tapped counterbore holes differ from standard counterbores primarily in the presence of internal threading in the lower hole. This threading requires precise coordination between the counterbore diameter, the threaded hole diameter, and the thread pitch. While a standard counterbore focuses solely on accommodating a screw head, a tapped counterbore must also align with screw threading standards (e.g., metric or imperial threads) to ensure compatibility with fasteners.

The depth of the counterbore and the threaded section must be carefully calculated. The counterbore depth should fully recess the screw head, while the threaded section must be deep enough to engage the screw securely without penetrating critical internal layers of the PCB, such as power or ground planes. This precision differentiates tapped counterbore design from its non - threaded counterpart, requiring a more intricate balance of mechanical and electrical considerations.

Material Considerations for Threaded Holes

Aluminum's malleability presents unique challenges for tapped counterbore holes. Unlike harder materials, aluminum can strip or deform under excessive torque, compromising thread integrity. To mitigate this, manufacturers often employ strategies such as:

Using thread - forming screws that create their own threads in the aluminum, reducing stripping risks.

Applying thread - locking compounds to enhance grip and prevent loosening due to vibrations.

Incorporating insert materials, such as brass or stainless steel threaded inserts, which provide stronger thread engagement in the aluminum substrate.

The choice of insert material must also consider galvanic corrosion risks between the insert and the aluminum board. Protective coatings or compatible material pairings (e.g., nickel - plated brass inserts) are essential to ensure long - term reliability.

Design Principles for Tapped Counterbore Holes

Mechanical Design Considerations

Thread Engagement and Torque Limits

The length of thread engagement in a tapped counterbore hole is critical for mechanical strength. As a general guideline, the thread engagement length should align with the screw diameter in aluminum, though this varies by application. Insufficient engagement can lead to screw pull - out, while excessive engagement may penetrate sensitive PCB layers.

Torque limits must be defined to prevent over - tightening, which causes aluminum deformation or thread stripping. Engineers reference torque - tension charts specific to aluminum and screw materials to establish safe tightening parameters. In high - vibration environments (e.g., automotive or aerospace), anti - vibration designs like serrated screw heads or lock washers may be integrated with tapped counterbores for added security.

Stress Distribution and Board Thickness

The thickness of the aluminum substrate directly impacts the tapped counterbore design. Thinner boards require shorter threaded sections to avoid breakthrough, while thicker boards allow deeper threads for stronger engagement. Finite Element Analysis (FEA) is often used to simulate stress distribution around the tapped hole, ensuring the board can withstand applied forces without cracking.

Electrical Design Considerations

Grounding and Electrical Connectivity

In applications where the screw serves as a grounding conductor, the tapped counterbore must facilitate low - resistance electrical paths. This involves:

Ensuring the screw makes direct contact with the aluminum substrate through the counterbore.

Minimizing oxidation or contamination between the screw and the board, which can increase resistance.

Using conductive thread - locking compounds or anti - oxidant coatings to maintain connectivity over time.

Clearance from Electrical Traces

Tapped counterbore holes must be positioned with adequate clearance from nearby copper traces to prevent short - circuits. The minimum distance between the hole and traces is determined by the voltage levels and trace widths, with industry standards (e.g., IPC - 2221) guiding safe spacing. In high - density PCBs, designers may use CAD tools to simulate electromagnetic interference (EMI) and ensure the tapped holes do not disrupt signal integrity.

Manufacturing Processes for Tapped Counterbore Holes

Drilling and Counterboring

The manufacturing process begins with precision drilling of the initial hole using high - speed CNC machines. Specialized carbide drills are used to prevent burr formation in the aluminum substrate. Following this, a counterboring tool creates the upper recess, with parameters like speed and feed rate optimized to achieve a smooth, burr - free surface.

Threading Techniques

Mechanical Tapping

Mechanical tapping involves using a tap tool to cut internal threads in the lower hole. This process requires precise control to avoid over - tapping, which can thin the aluminum wall and reduce thread strength. Coolants are often applied to dissipate heat and prevent tool wear, especially in high - volume production.

Thread Insert Installation

For enhanced thread durability, threaded inserts (e.g., press - fit or heat - staked inserts) may be installed after drilling. This is particularly common in high - torque applications. The insert installation process must align with the counterbore depth to ensure the screw head sits flush with the board surface.

Surface Treatment and Finishing

To improve thread durability and prevent corrosion, the tapped holes may undergo surface treatments such as:

Anodizing: Enhances corrosion resistance and provides a hard surface for thread engagement.

Electroless Nickel Immersion Gold (ENIG): Improves solderability and electrical conductivity for grounding applications.

Plating: Applying a thin metal layer (e.g., nickel or tin) to protect aluminum threads from wear and oxidation.

Quality Control and Testing

Dimensional Inspection

Precision measuring tools like coordinate measuring machines (CMMs) verify counterbore diameter, thread pitch, and depth. Thread gages are used to check internal thread accuracy, ensuring compatibility with standard fasteners. Any deviation from design specifications— such as an undersized counterbore that leaves the screw head protruding— is considered a defect.

Thread Integrity Testing

Torque - testing machines apply controlled forces to assess thread strength and prevent stripping. This involves:

Torque - to - failure tests: Measuring the torque required to strip the threads.

Proof load tests: Ensuring the threads can withstand specified clamping forces without deformation.

Electrical Continuity Testing

In applications where the tapped counterbore serves as a grounding point, electrical continuity tests are performed. A micro - ohmmeter measures resistance between the screw and the board's ground plane, with values typically required to be below a specified threshold (e.g., milliohms) to ensure reliable conductivity.

Industry Applications of Tapped Counterbore Holes

Aerospace and Defense

In avionics and defense systems, tapped counterbore holes are essential for:

Mounting high - reliability components in aircraft, where vibrations and temperature fluctuations are extreme.

Grounding sensitive radar and communication equipment to prevent EMI.

Attaching heat sinks to aluminum PCBs, combining mechanical fixation with thermal conductivity.

The use of threaded inserts in these applications ensures long - term reliability, even in harsh environments where component failure could have catastrophic consequences.

Automotive Electronics

In automotive ECUs and sensor modules, tapped counterbores enable:

Secure mounting of components in engine compartments, resistant to vibrations and temperature cycles.

Electrical grounding of power electronics to the aluminum substrate for EMI suppression.

Integration of heat - dissipating components, such as power transistors, with direct contact to the PCB's thermal plane.

Thread - locking compounds are commonly used here to prevent loosening during vehicle operation.

Medical Devices

In medical equipment, tapped counterbore holes are valued for:

Sterilizable designs in surgical tools or implantable devices, where smooth surfaces and corrosion resistance are critical.

Precise component mounting in diagnostic equipment, ensuring stability during operation.

Electrical grounding in imaging systems to minimize signal interference.

Biocompatible coatings on threaded inserts are often required to meet medical industry standards.

Consumer Electronics

In slim - profile devices like laptops or wearables, tapped counterbores allow:

Flush mounting of internal components to reduce device thickness.

Grounding of shielding covers to prevent EMI in wireless modules.

Reusable fasteners for serviceability, a key consideration in repairable product designs.

Future Trends and Challenges

Miniaturization and Micro - Threading

As electronics shrink, tapped counterbore holes are being adapted for micro - threading (e.g., M1 or smaller threads). This requires advanced micro - machining techniques and specialized taps, along with tighter quality control for thread consistency in miniature holes.

Composite Materials Integration

The adoption of aluminum - composite PCBs (e.g., aluminum cores with composite dielectric layers) presents challenges for threading. Manufacturers are developing hybrid solutions, such as laser - drilled holes with composite - compatible inserts, to maintain thread strength in multi - material boards.

Sustainable Manufacturing

Eco - friendly practices are driving the use of water - based coolants in tapping processes and lead - free plating for thread protection. Additionally, recyclable insert materials are being explored to reduce electronic waste.

Automated Inspection Technologies

AI - powered visual inspection systems are being implemented to detect microscopic thread defects, such as incomplete threads or burrs, ensuring higher yields in high - volume production.

Conclusion

Tapped counterbore holes in aluminum circuit boards represent a fusion of mechanical and electrical engineering, enabling secure component mounting and reliable conductivity in demanding applications. As electronics continue to evolve toward smaller, more robust designs, the precision and innovation behind tapped counterbore technology will remain critical. By addressing challenges in material compatibility, miniaturization, and sustainability, manufacturers can unlock new possibilities for aluminum PCBs in aerospace, automotive, medical, and consumer electronics— ensuring that tapped counterbores remain an essential feature in advanced electronic systems.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB