-

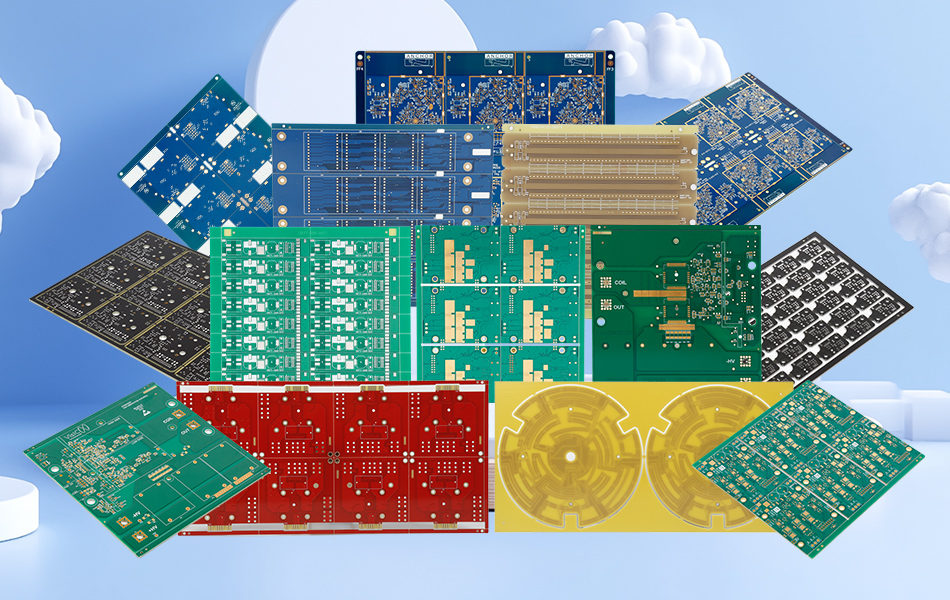

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 11. 2025, 16:09:11

In the spectrum of FR4 PCB materials, the Tg150 FR4 PCB Material Specification represents a critical middle ground, offering enhanced thermal stability without the complexity of ultra-high-temperature variants. "Tg150" refers to the material’s glass transition temperature—the point at which the epoxy resin shifts from a rigid to a rubbery state—set at 150°C, making it suitable for applications where moderate heat resistance is required. This specification bridges the gap between standard FR4 (with lower Tg) and specialized high-temperature materials, providing a balance of performance, cost, and processability. This article explores the defining features of Tg150 FR4, its role in electronics manufacturing, key elements of its specification, and its ideal applications, highlighting why it has become a go-to choice for industries needing reliable thermal performance in diverse operating conditions.

At its core, Tg150 FR4 PCB Material Specification is defined by its glass transition temperature (Tg) of 150°C, a key thermal property that dictates the material’s ability to maintain structural and electrical integrity under heat. Unlike standard FR4, which is designed for milder environments, Tg150 FR4 is formulated to withstand sustained temperatures closer to its Tg without significant degradation.

The Tg value is not arbitrary; it is carefully engineered to meet the demands of applications where heat generation is moderate but consistent. This includes devices with components that produce steady heat during operation, such as power supplies, automotive control modules, and industrial sensors. By setting the Tg at 150°C, the material provides a safety margin—ensuring reliable performance even when operating temperatures rise above typical consumer electronics levels but remain below the extremes requiring ultra-high-Tg materials.

Tg150 FR4 retains the core structure of other FR4 variants: a glass fiber-reinforced epoxy matrix. However, its resin formulation is modified to enhance thermal stability, often using advanced epoxy resins that resist softening at higher temperatures. This modification allows it to maintain mechanical rigidity and electrical insulation properties in conditions where standard FR4 would begin to compromise performance.

The specification for Tg150 FR4 encompasses several critical aspects that ensure consistency and performance across manufacturers:

While avoiding specific metrics, the specification outlines the material’s ability to function reliably near its Tg. This includes resistance to warping, delamination, or loss of insulation when exposed to sustained temperatures below 150°C, as well as short-term exposure to higher temperatures during manufacturing processes like soldering.

The specification details the type of epoxy resin used—typically a modified bisphenol or novolac-based resin—to achieve the 150°C Tg. It also specifies the glass fiber reinforcement (often E-glass or a hybrid weave) to ensure mechanical stability at elevated temperatures, preventing dimensional changes that could disrupt component alignment.

Like all FR4 materials, Tg150 variants must meet flame retardancy standards (such as UL94 V-0) to ensure safety in case of fire. The specification includes compliance with global safety regulations, ensuring the material is suitable for use in consumer, automotive, and industrial products.

The specification confirms that Tg150 FR4 maintains reliable electrical insulation even at elevated temperatures. This is critical for preventing signal interference or leakage in heat-generating components, ensuring consistent performance in power circuits and high-current applications.

A key aspect of the specification is guidance on processing Tg150 FR4, including recommendations for lamination temperatures, curing times, and drilling techniques. This ensures manufacturers can handle the material effectively using equipment adapted for moderate high-temperature FR4 variants, balancing performance with production practicality.

Tg150 FR4 occupies a unique position in the FR4 family, distinct from both standard and higher-Tg variants:

Compared to Standard FR4 (Lower Tg): Standard FR4 is designed for temperatures well below 100°C, making it unsuitable for applications with sustained heat. Tg150 FR4, by contrast, maintains stability in environments where temperatures regularly reach 100–120°C, such as inside power adapters or automotive engine bays (non-extreme areas).

Compared to Ultra-High-Tg FR4 (Tg >180°C): Ultra-high-Tg materials are engineered for extreme heat, such as industrial ovens or aerospace systems. Tg150 FR4, while thermally robust, does not require the specialized resins or manufacturing processes of these variants, making it more cost-effective and easier to process for applications that do not demand extreme heat resistance.

Compared to Halogen-Free or Low-Dielectric FR4: These variants prioritize environmental safety or signal integrity, respectively. Tg150 FR4 may incorporate halogen-free flame retardants or low-dielectric properties, but its defining feature remains its thermal stability, making it a complementary rather than competing choice.

This middle-ground positioning makes Tg150 FR4 a versatile option, avoiding the over-engineering of ultra-high-Tg materials while exceeding the capabilities of standard FR4.

Tg150 FR4 is particularly well-suited for applications where moderate, sustained heat is a factor but extreme temperatures are not a concern:

Power Electronics: Power supplies, inverters, and battery management systems generate consistent heat during operation. Tg150 FR4 withstands the thermal stress of these components, preventing warpage or insulation breakdown in circuits handling 10–50W of power.

Automotive Electronics: In-vehicle systems such as infotainment controllers, climate control modules, and lighting ballasts operate in temperatures that can exceed 100°C, especially in enclosed cabin spaces. Tg150 FR4 provides the necessary thermal stability without the cost of automotive-grade ultra-high-Tg materials.

Industrial Sensors and Controls: Factory automation sensors, motor drives, and process control units often operate in warm environments. Tg150 FR4 ensures these devices remain reliable in temperatures typical of industrial facilities, where ambient heat and component-generated warmth combine.

LED Lighting Systems: High-power LED fixtures (e.g., commercial lighting, outdoor floodlights) generate significant heat around their driver circuits. Tg150 FR4 prevents the PCBs in these drivers from degrading, extending the lifespan of the lighting systems.

Medical Equipment: Devices like diagnostic scanners and therapeutic equipment may have internal components that generate steady heat. Tg150 FR4 ensures these devices maintain performance and safety in controlled but warm operating conditions.

In each of these applications, Tg150 FR4 strikes a balance: it provides enough thermal resistance to avoid failure, yet remains cost-effective and easy to process compared to more specialized materials.

While Tg150 FR4 is more process-friendly than ultra-high-Tg variants, it requires adjustments compared to standard FR4:

Lamination: The modified resins in Tg150 FR4 may require slightly higher curing temperatures and longer dwell times to ensure full cross-linking. This ensures the material achieves its rated Tg and mechanical strength, preventing premature softening under heat.

Drilling and Routing: The resin’s enhanced thermal stability can make it slightly more rigid, requiring sharpened tools to ensure clean cuts. Manufacturers may adjust drill speeds to avoid excessive friction, which could damage the material or tooling.

Solder Reflow: Tg150 FR4 withstands higher reflow temperatures than standard FR4, making it compatible with lead-free soldering processes (which use higher temperatures than traditional leaded solder). This compliance is critical for meeting global environmental regulations.

Quality Control: Testing for Tg confirmation is essential, typically using thermal analysis techniques to verify that the material meets the 150°C specification. This ensures consistency across production batches, a key factor for reliability in heat-sensitive applications.

These considerations are manageable with standard manufacturing equipment adapted for moderate high-temperature materials, making Tg150 FR4 accessible to most PCB manufacturers.

One of the primary advantages of Tg150 FR4 is its ability to balance performance and cost, making it a cost-effective choice for many applications:

Avoiding Over-Engineering: Using ultra-high-Tg materials in applications that only require moderate heat resistance adds unnecessary cost. Tg150 FR4 provides sufficient thermal stability at a lower price point, reducing material expenses without compromising reliability.

Simplified Manufacturing: Unlike ultra-high-Tg variants, Tg150 FR4 does not require specialized production lines or expensive tooling, lowering manufacturing costs. This makes it accessible to smaller manufacturers or projects with tight budgets.

Reduced Rework: The material’s thermal stability minimizes the risk of post-production failures due to heat-related issues, such as delamination or warping. This reduces rework costs and improves overall production efficiency.

For design engineers, specifying Tg150 FR4 allows them to meet performance requirements without inflating project costs, a critical factor in competitive markets like consumer electronics and automotive parts.

Several myths surround Tg150 FR4, often leading to underutilization or misapplication:

"Tg150 FR4 is only for extreme heat": In reality, it is designed for moderate heat, making it overkill for standard consumer devices but ideal for applications with sustained temperatures above 100°C.

"It’s interchangeable with standard FR4": While both are FR4 variants, their thermal capabilities differ significantly. Substituting standard FR4 for Tg150 in heat-prone applications can lead to premature failure.

"Higher Tg is always better": This ignores cost and processability. Tg150 FR4 is often the optimal choice for applications that do not require ultra-high temperatures, avoiding unnecessary expense.

"Tg150 FR4 is difficult to source": As demand has grown, most major FR4 suppliers now offer Tg150 variants, ensuring consistent availability and competitive pricing.

Understanding these misconceptions helps engineers and manufacturers make informed decisions, ensuring Tg150 FR4 is used where it provides the most value.

As electronics continue to evolve, Tg150 FR4 is adapting to meet new demands:

Enhanced Sustainability: Manufacturers are developing Tg150 FR4 with bio-based resins or recycled glass fibers, reducing environmental impact while maintaining thermal performance. This aligns with the industry’s shift toward eco-friendly materials.

Hybrid Formulations: Combining Tg150 thermal stability with other properties—such as halogen-free flame retardancy or low dielectric loss—creates multi-functional materials suitable for complex applications like electric vehicle charging systems.

Improved Processability: Advances in resin chemistry are making Tg150 FR4 easier to laminate and drill, reducing manufacturing time and costs while retaining its thermal benefits.

These developments ensure Tg150 FR4 remains relevant, adapting to the needs of emerging technologies like renewable energy systems and smart industrial equipment.

The Tg150 FR4 PCB Material Specification fills a critical niche in the electronics industry, offering a practical balance of thermal performance, cost, and processability. By targeting applications with moderate, sustained heat requirements, it avoids the over-engineering of ultra-high-Tg materials while exceeding the capabilities of standard FR4. Its defining feature—150°C glass transition temperature—ensures reliability in power electronics, automotive systems, and industrial equipment, where heat generation is a constant but not extreme factor. As manufacturing processes improve and formulations evolve, Tg150 FR4 will continue to play a key role in cost-effective, reliable design, supporting the next generation of heat-sensitive electronic devices. For engineers and manufacturers, understanding its specification and applications is essential to leveraging its full potential in diverse and demanding environments.

[Get a Free Quote & Thermal Analysis for Your Aluminum PCB Project Today]

Related Articles

FR4 PCB Manufacturer | High Tg & Reliable PCB Material FR4 Solutions

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

LED Lighting FR4 PCB: Technical Foundations for Illumination Systems

FR4 PCB Manufacturer for Prototype and Mass Production

FR4 PCB Thermal Conductivity: A Comprehensive Guide to Heat Management

Tg170 FR4 PCB Datasheet PDF: A Detailed Exploration of High-Tg Laminate Specifications

Tg130 FR4 PCB Material Datasheet: Engineering Fundamentals and Industry Applications

Countersink Holes in FR4 PCB: Engineering Principles for Precision Assembly

HDI Blind/Buried Vias FR4 PCB: High-Density Interconnect Solutions for Advanced Electronics

FR4 PCB Material Specification Sheet: A Comprehensive Technical Guide

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB