-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 26. 2025, 10:14:01

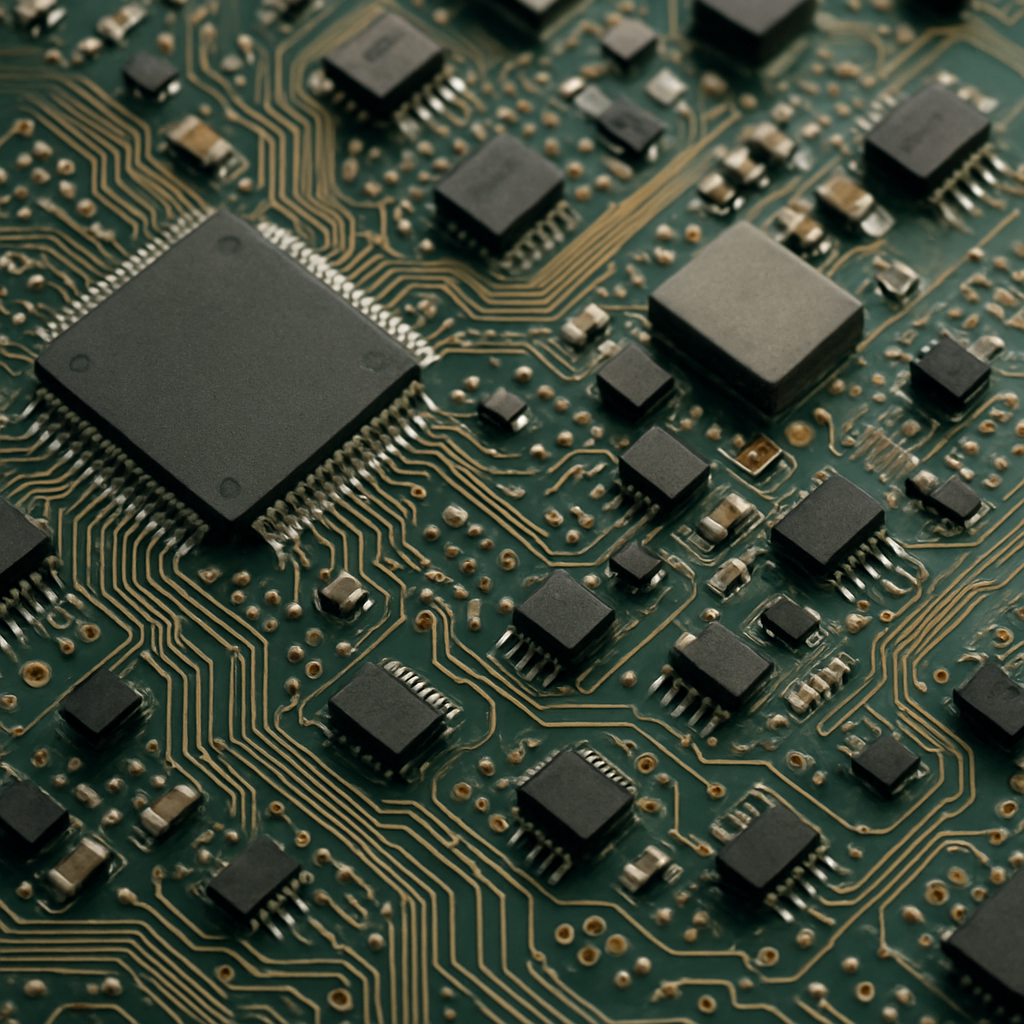

When it comes to bringing your electronic projects to life, choosing the right printed circuit board (PCB) manufacturer is crucial. The quality of your PCBs impacts the performance and reliability of your final product. Whether you're a hobbyist, a startup, or an established company, selecting the right partner for PCB design, manufacturing, and assembly is essential. In this article, we'll guide you through the key factors to consider when choosing a PCB manufacturer to ensure your needs are met.

Before diving into the selection process, it's important to clearly understand your specific PCB requirements. This involves considering the complexity of your PCB design, the quantity needed, and any unique features or specifications your project may require.

The complexity of your PCB design will influence your choice of manufacturer. Simple designs might not require the same level of expertise as more complex, multilayer PCBs. Ensure that the manufacturer you choose has the capability and experience to handle your design's intricacy.

Consider the production volume you anticipate. Some manufacturers specialize in small batches, catering to prototypes and low-volume production, while others are equipped to handle large-scale manufacturing. Choose a manufacturer that aligns with your production needs.

If your PCB design includes special features, such as specific materials or unique layouts, it's crucial to communicate these requirements upfront. Not all manufacturers can accommodate every specification, so finding one that can meet your needs is essential.

Once you have a clear understanding of your needs, it's time to research potential PCB manufacturers. Here are some factors to consider during your search:

A manufacturer's reputation is a strong indicator of their reliability and quality. Look for reviews and testimonials from previous clients to gauge their level of satisfaction. Additionally, consider the manufacturer's experience in the industry. Established manufacturers are more likely to have streamlined processes and quality assurance measures in place.

Evaluate the range of services offered by the manufacturer. Do they provide both PCB design and assembly services, or do they focus solely on manufacturing? A manufacturer that offers a comprehensive suite of services can simplify the production process by handling everything from design to assembly.

Quality is paramount when it comes to PCBs. Ensure that the manufacturer adheres to industry standards and holds relevant certifications, such as ISO 9001 or IPC-A-610. These certifications demonstrate a commitment to quality and reliability.

Advanced technology and equipment can significantly impact the quality and precision of your PCBs. Inquire about the manufacturer's equipment and technology to ensure they are up to date with the latest advancements in PCB manufacturing.

Cost and lead time are critical factors in the decision-making process. While it's tempting to choose the cheapest option, it's important to balance cost with quality and reliability.

Understand the manufacturer's pricing structure and what is included in the cost. Some manufacturers offer all-inclusive pricing, while others may charge separately for design, manufacturing, and assembly. Compare quotes from multiple manufacturers to ensure you're getting a fair deal.

Lead time can vary significantly between manufacturers. Consider your project's timeline and choose a manufacturer that can meet your deadlines. Additionally, inquire about their delivery options and whether they offer expedited services if needed.

If possible, visit the manufacturer's facility to get a firsthand look at their operations. This can provide valuable insights into their processes, quality control measures, and overall professionalism. During your visit, ask questions about their production capacity, quality assurance procedures, and any other concerns you may have.

Once you've chosen a PCB manufacturer, focus on building a strong partnership. Effective communication and collaboration are key to ensuring a successful production process.

Establish clear lines of communication with your manufacturer. Regular updates and open dialogue can help prevent misunderstandings and ensure that your project stays on track.

Provide feedback throughout the production process and be open to iteration. This collaborative approach can lead to improvements in the final product and strengthen your relationship with the manufacturer.

Consider the potential for a long-term relationship with your chosen manufacturer. A reliable partner can provide consistency and support for future projects, saving you time and effort in the long run.

Choosing the right PCB manufacturer is a critical step in bringing your electronic projects to life. By understanding your needs, researching potential manufacturers, evaluating costs, and building a strong partnership, you can ensure that your PCBs meet the highest standards of quality and reliability. Take the time to make an informed decision, and you'll set the foundation for successful electronic projects now and in the future.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB