-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 10. 2025, 19:23:30

Choosing the right PCB (Printed Circuit Board) manufacturer is crucial for the success of your electronic projects. Whether you're a hobbyist or a professional engineer, the manufacturer you choose can make or break your project. In this guide, we will explore the key factors to consider when selecting a PCB manufacturer that fits your specific needs.

Before diving into the selection process, it's important to understand what a PCB is. A Printed Circuit Board is a board used to mechanically support and electrically connect electronic components using conductive pathways. They are found in almost every electronic device today.

PCB design is a critical step in the development of electronic devices. A well-designed PCB ensures that the device operates efficiently and reliably. This involves laying out the circuit in a way that minimizes interference and optimizes performance. Therefore, when choosing a manufacturer, you should ensure they are capable of producing high-quality designs that meet your specifications.

When selecting a PCB manufacturer, several factors should be taken into account to ensure you make the right choice.

Quality should be your top priority. Look for manufacturers that adhere to international standards and have certifications such as ISO 9001. This ensures that their production processes meet the highest quality standards.

Experience matters in the PCB industry. Manufacturers with a long history are likely to have refined their processes and technology. Researching customer reviews and testimonials can provide insight into the manufacturer's reputation and reliability.

Different projects require different manufacturing capabilities. Ensure that the manufacturer you choose can handle the complexity and scale of your project. Consider the following:

Layer count: Can they produce multi-layer boards if needed?

Material types: Do they offer a variety of materials for different applications?

Board thickness and size: Can they produce boards that meet your specifications?

Time is often a critical factor in project development. Discuss the estimated turnaround time with potential manufacturers and ensure it aligns with your project timeline. Some manufacturers offer expedited services if you need your PCBs quickly.

While cost shouldn't be the only factor, it's still important. Obtain quotes from multiple manufacturers and compare them. Be wary of prices that seem too good to be true, as they may reflect lower quality.

Customer Support

Effective communication is key. A manufacturer with excellent customer support can provide guidance throughout the manufacturing process, making it easier to address any issues that arise.

Some PCB manufacturers offer additional services that can add value to your project.

Prototyping is an essential step in the development process. It allows you to test and refine your design before committing to full-scale production. Choose a manufacturer that offers prototyping services to ensure your design functions as intended.

If you're new to PCB design or need help optimizing your layout, some manufacturers offer design assistance. This can be particularly beneficial for complex projects where expert advice can prevent costly mistakes.

Some manufacturers also offer PCB assembly services, where they will place and solder components onto the board for you. This can save you time and ensure that the components are correctly placed and soldered.

After evaluating the factors above, you should have a shortlist of potential PCB manufacturers. Here are some final steps to help make your decision:

Request samples: If possible, request samples of their work to assess quality firsthand.

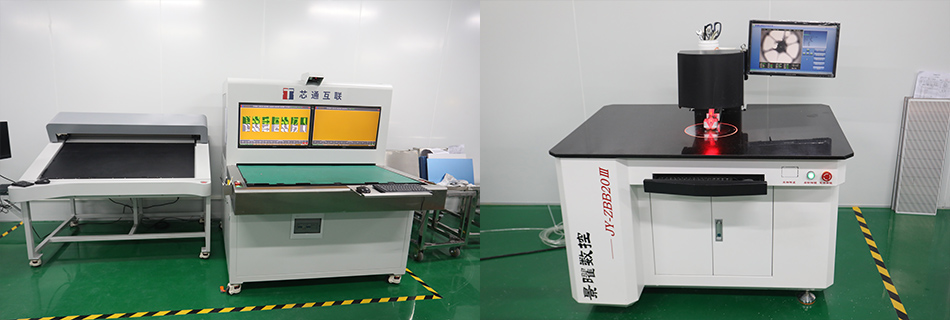

Visit the facility: If feasible, visiting the manufacturer's facility can provide a better understanding of their capabilities and processes.

Check references: Ask for references from previous clients to gain insight into their experience working with the manufacturer.

Choosing the right PCB manufacturer is a crucial step in the success of your electronic projects. By considering factors such as quality, experience, manufacturing capabilities, and additional services, you can select a manufacturer that meets your needs and ensures the success of your project. With the right partner, you can bring your electronic designs to life with confidence.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB