-

- PCB TYPE

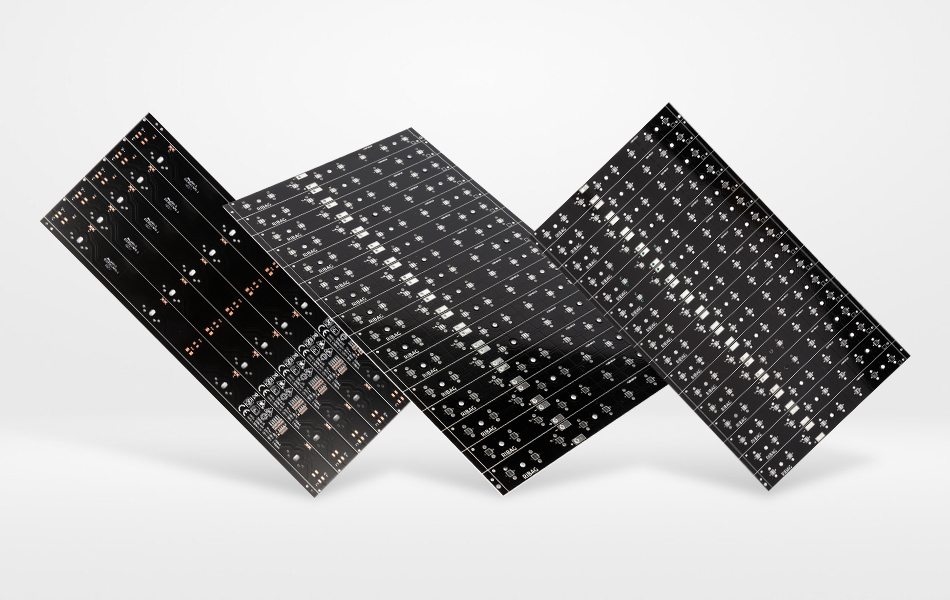

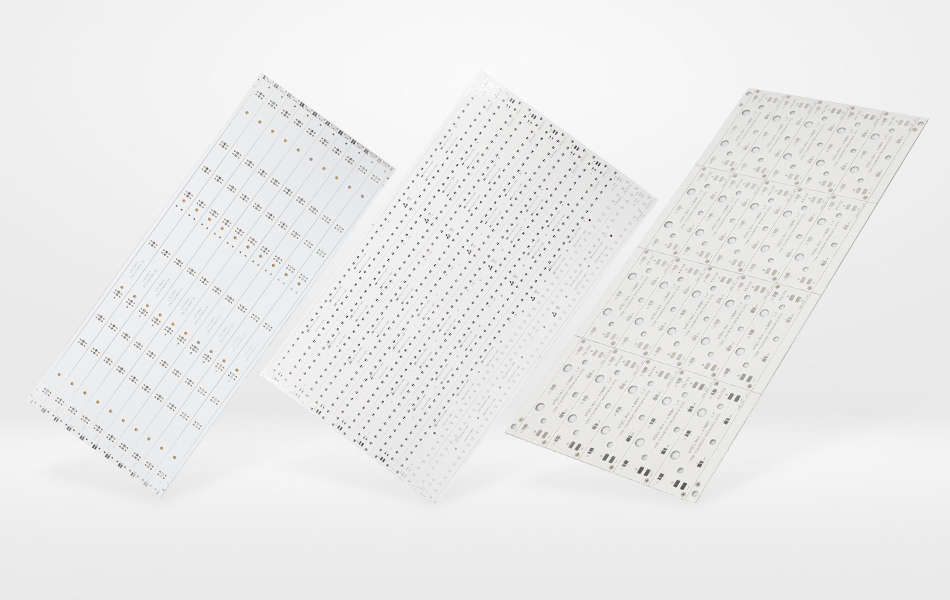

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 19. 2025, 10:21:47

In the rapidly evolving landscape of high-performance electronics, Ventec Aluminum Based CCL (Copper Clad Laminate) has emerged as a cornerstone material, redefining thermal management, reliability, and design flexibility. As industries like automotive electrification, 5G telecommunications, and industrial automation demand increasingly power-dense components, traditional FR-4 PCBs struggle to dissipate heat efficiently. Ventec’s aluminum-based CCLs address this gap through advanced material engineering, offering a unique synergy of thermal conductivity, electrical insulation, and mechanical robustness. This article explores the technical foundations, application ecosystems, sustainability initiatives, and future trends of Ventec Aluminum Based CCLs, emphasizing their role in enabling next-generation electronic systems.

Core Architecture and Material Engineering

Ventec Aluminum Based CCLs are engineered as multi-layer composites, each component optimized for performance:

Structural Layers

Aluminum Substrate: The foundational layer, selected for its high thermal diffusivity and lightweight properties. Unlike rigid copper substrates, aluminum balances heat dissipation with structural flexibility, making it suitable for both static and dynamic applications (e.g., automotive sensors, portable devices).

Advanced Dielectric Layer: A proprietary blend of ceramic-reinforced polymers or high-performance polyimides forms the insulating barrier between the aluminum substrate and copper circuit layer. This layer is formulated to enhance thermal transfer while maintaining high dielectric strength, critical for preventing signal interference in high-frequency circuits.

Copper Circuit Layer: Thin, high-purity copper foil is bonded to the dielectric via Ventec’s proprietary lamination processes, minimizing interface resistance. This layer acts as both an electrical conductor and a thermal bridge, channeling heat from active components to the aluminum substrate.

The integration of these layers creates a thermal-electrical synergy, where heat flows unimpeded from components through the copper layer, across the dielectric, and into the aluminum substrate—eliminating the thermal bottlenecks common in conventional PCBs.

Key Performance Advantages

Ventec Aluminum Based CCLs outperform traditional materials in three critical areas:

Thermal Management Excellence

Enhanced Heat Dissipation: The aluminum substrate’s intrinsic thermal conductivity, combined with a low-thermal-resistance dielectric, enables rapid heat spreading. This is pivotal for high-power components like LEDs, power transistors, and motor drivers, where excessive heat reduces efficiency and lifespan.

Thermal Cycling Stability: The material’s coefficient of thermal expansion (CTE) is meticulously engineered to match copper and semiconductor materials, minimizing stress during temperature fluctuations. This reduces delamination risks, a common failure mode in electronics exposed to harsh environments.

Electrical and Mechanical Reliability

High Dielectric Strength: The dielectric layer maintains stable insulation even under high voltages, making Ventec CCLs suitable for automotive inverters and industrial power supplies operating at 400V+ levels.

Mechanical Durability: Aluminum’s inherent rigidity resists warping under mechanical stress, while surface treatments (e.g., anodization) enhance corrosion resistance—critical for outdoor applications like solar inverters and 5G base stations.

Design Versatility

Adaptable Thickness Profiles: Ventec offers aluminum based CCLs in varied thicknesses, from ultra-thin (for compact wearables) to robust substrates (for industrial machinery), supporting diverse design requirements.

Compatibility with Advanced Manufacturing: These CCLs integrate seamlessly with HDI (High-Density Interconnect) and SMT (Surface Mount Technology) processes, enabling miniaturization and high component density in modern electronics.

Industry Applications: Driving Innovation Across Sectors

Ventec Aluminum Based CCLs are integral to transformative technologies in key industries:

Automotive Electrification

EV Power Systems: In electric vehicle inverters, battery management systems (BMS), and onboard chargers, these CCLs dissipate heat from high-current components, ensuring reliable operation in temperature extremes (-40°C to 150°C).

ADAS and Vehicle Lighting: Advanced driver-assistance systems (ADAS) rely on Ventec CCLs for thermal stability in radar and LiDAR modules, while automotive LED headlights benefit from reduced thermal degradation, extending service life.

5G and Telecommunications

Base Station Infrastructure: High-frequency 5G transceivers and RF amplifiers generate significant heat; Ventec’s CCLs maintain signal integrity by minimizing dielectric loss and efficiently dissipating heat, critical for network reliability.

Data Center Hardware: Server motherboards and power distribution units (PDUs) use aluminum based CCLs to manage thermal hotspots, supporting higher computational densities in cloud infrastructure.

Industrial and Renewable Energy

Industrial Automation: Motor drives, PLCs (Programmable Logic Controllers), and sensor modules in factory automation systems depend on Ventec CCLs for resistance to vibration, dust, and temperature cycles.

Solar and Energy Storage: Solar inverters and battery energy storage systems (BESS) utilize these CCLs to optimize power conversion efficiency, withstanding outdoor conditions while reducing energy loss from heat buildup.

Manufacturing and Quality Assurance

Ventec’s production of aluminum based CCLs combines precision engineering with rigorous quality control:

Advanced Lamination Processes

Proprietary Bonding Technologies: Ventec’s lamination methods ensure uniform adhesion between the aluminum substrate, dielectric, and copper layer, minimizing interface resistance. This precision is achieved through controlled pressure and temperature profiles, tailored to each material formulation.

Automated Inspection: In-line thermal imaging and ultrasonic testing detect defects (e.g., delamination, uneven coating) in real time, ensuring consistent performance across production batches.

Compliance and Certifications

Automotive Standards: IATF 16949 certification validates adherence to automotive quality management systems, critical for components used in vehicle safety systems.

Electrical Safety: UL 94 V-0 flammability ratings and IPC-4101 compliance ensure suitability for high-voltage and high-reliability applications.

Environmental Compliance: RoHS and REACH certifications confirm the absence of hazardous substances, aligning with global sustainability regulations.

Sustainability and Circular Economy

Ventec Aluminum Based CCLs align with global efforts to reduce electronic waste and carbon footprints:

Material Efficiency

Recyclable Core Materials: Aluminum substrates are highly recyclable, with closed-loop recycling programs at Ventec facilities reducing raw material consumption.

Low-Impact Formulations: Halogen-free dielectrics and lead-free copper bonding eliminate toxic substances, supporting eco-friendly electronics manufacturing.

Energy-Efficient Production

Lean Manufacturing: Ventec’s facilities optimize energy use through renewable energy integration (e.g., solar-powered production lines) and waste reduction, achieving ISO 14001 environmental management certification.

Longevity in Service: By extending the lifespan of electronic components through superior thermal management, these CCLs reduce the frequency of replacements, lowering overall environmental impact.

Future Trends and Innovations

Ventec continues to advance aluminum based CCL technology to meet emerging industry needs:

Next-Gen Dielectric Materials

Nano-Enhanced Polymers: Research into ceramic nanoparticles (e.g., boron nitride, aluminum oxide) in dielectric layers aims to boost thermal conductivity further without sacrificing electrical insulation.

Bio-Based Composites: Exploration of plant-derived polymers in dielectric formulations could reduce reliance on fossil fuels, aligning with circular economy goals.

Smart Thermal Integration

Embedded Sensing: Integration of thin-film temperature sensors within CCLs enables real-time thermal monitoring, supporting adaptive cooling systems in high-power applications like EV inverters.

AI-Driven Design: Machine learning algorithms optimize CCL layer thickness and material distribution, tailoring thermal performance to specific application requirements (e.g., 5G transceivers vs. industrial sensors).

Expanding Application Frontiers

Aerospace and Defense: Lightweight aluminum based CCLs are being tested for use in unmanned aerial vehicles (UAVs) and satellite electronics, where weight reduction and thermal stability are critical.

Wearable Electronics: Ultra-thin, flexible variants of Ventec’s CCLs support compact, body-worn devices, combining thermal management with ergonomic design.

Conclusion

Ventec Aluminum Based CCLs represent a pivotal innovation in electronics materials, enabling the next generation of power-dense, reliable, and sustainable devices. By balancing thermal efficiency, electrical performance, and mechanical robustness, these materials address the core challenges of modern industries—from automotive electrification to 5G connectivity. As Ventec continues to advance material science and manufacturing precision, aluminum based CCLs will remain essential to unlocking innovations in electronics, driving efficiency, and reducing environmental impact. For engineers and designers, these materials offer a proven platform to push the boundaries of what’s possible in high-performance electronics.

Keywords: Ventec Aluminum Based CCL, thermal management, automotive electronics, 5G telecommunications, sustainable electronics, copper clad laminate, industrial automation.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB