-

- PCB TYPE

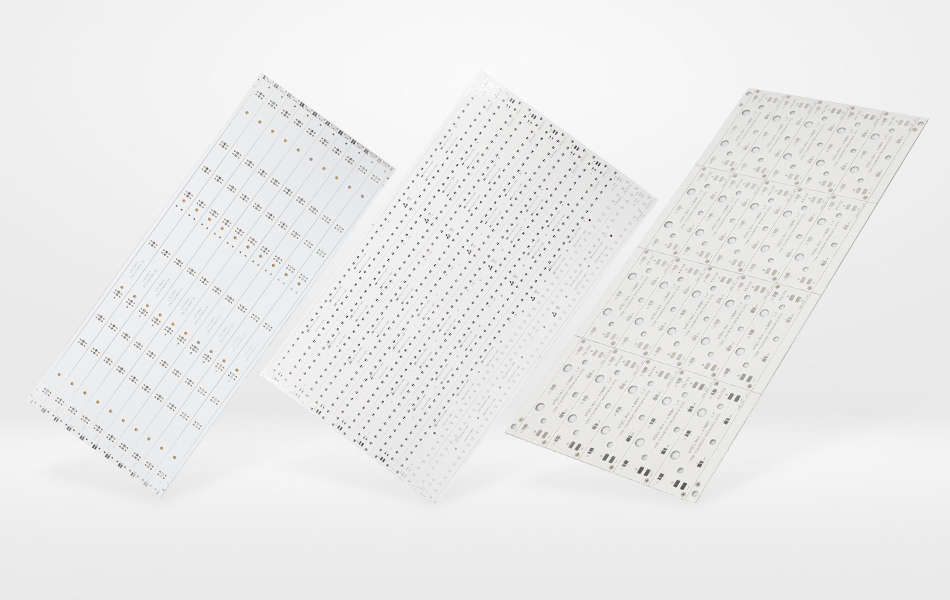

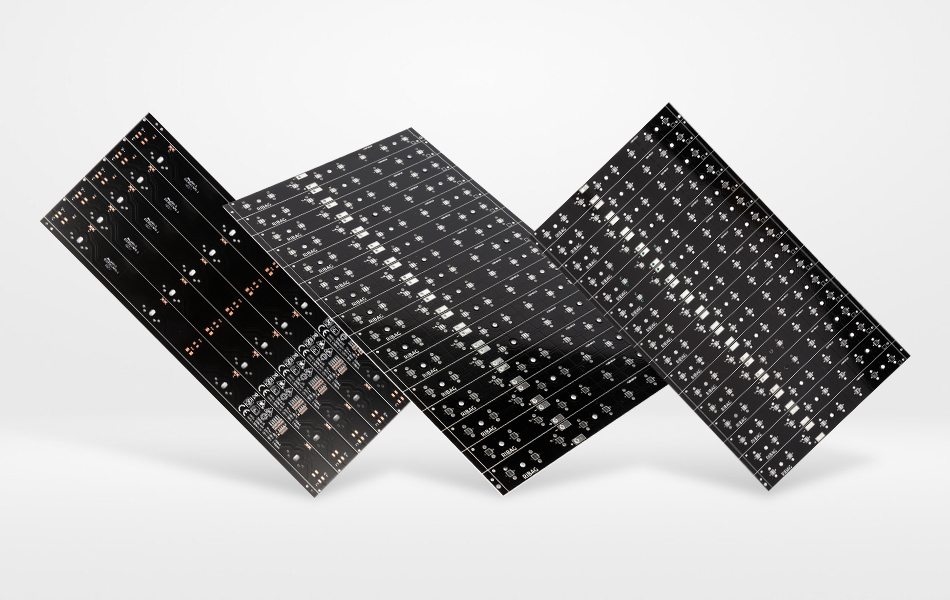

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 19. 2025, 10:14:53

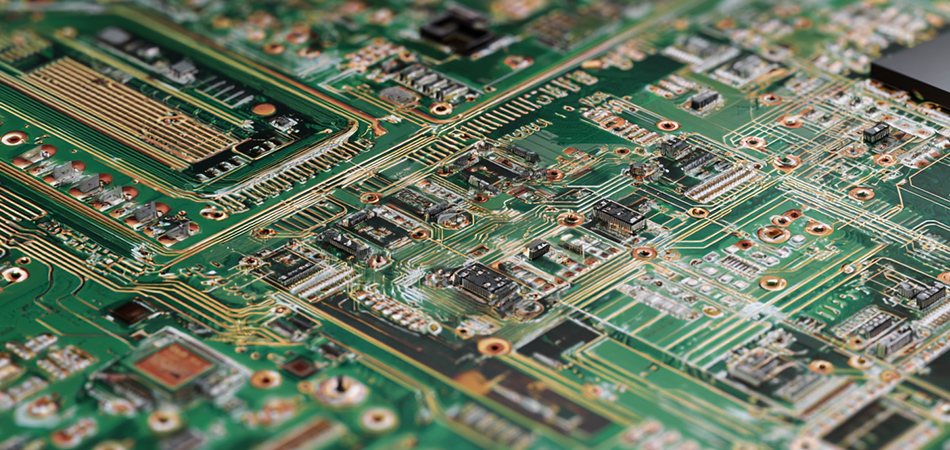

In the rapidly evolving landscape of electronic manufacturing, Ventec Aluminum Based Circuit Laminate has emerged as a transformative solution for high-performance circuits demanding superior thermal management, structural stability, and design flexibility. As industries from automotive electrification to next-gen telecommunications push the boundaries of power density and miniaturization, traditional circuit materials often fall short. This article explores the unique attributes, technical innovations, application diversity, and manufacturing advancements of Ventec’s aluminum-based circuit laminates, highlighting their role in enabling the next generation of electronic systems.

Defining Ventec Aluminum Based Circuit Laminate

Ventec Aluminum Based Circuit Laminate refers to a composite material engineered specifically for circuit board fabrication, integrating aluminum substrates with dielectric layers and conductive copper circuits. Unlike generic copper-clad laminates (CCLs), these specialized laminates are optimized for circuit performance—balancing electrical conductivity, thermal dissipation, and mechanical robustness to meet the demands of complex electronic architectures.

At its core, the laminate structure consists of three functional layers working in synergy:

Aluminum Core: Provides a thermally conductive foundation that doubles as a structural backbone, dissipating heat away from sensitive components while resisting warpage under thermal stress.

Engineered Dielectric: A proprietary polymer or ceramic-polymer blend that insulates the aluminum core from the copper circuit layer, preventing electrical shorting while facilitating efficient heat transfer.

Copper Circuit Layer: Precision-bonded to the dielectric, this layer forms the conductive pathways of the circuit, designed to minimize signal loss and maximize current-carrying capacity.

This architecture distinguishes Ventec’s offering from traditional FR-4 laminates, which lack the thermal conductivity to handle high-power applications, and pure metal substrates, which fail to provide electrical insulation.

Core Technical Advantages Over Traditional Materials

Thermal Management Superiority

The aluminum core’s high thermal conductivity creates a dynamic heat dissipation network that addresses a critical pain point in modern electronics: thermal buildup in dense circuits. Unlike FR-4, which traps heat around components, Ventec’s laminate channels heat laterally across the aluminum core, reducing hotspots by creating a larger thermal mass. This is particularly valuable in circuits with high-power components such as MOSFETs, voltage regulators, and RF amplifiers, where even small temperature increases can degrade performance or shorten lifespan.

The dielectric layer enhances this capability through material engineering—ceramic fillers (e.g., alumina, boron nitride) in the polymer matrix create microscale thermal bridges, improving heat transfer from the copper circuit to the aluminum core without compromising electrical insulation.

Mechanical Stability for Complex Designs

Electronic circuits in demanding environments (automotive, industrial, aerospace) require materials that withstand vibration, shock, and temperature cycling. Ventec’s aluminum-based laminate delivers:

High Stiffness: The aluminum core resists bending and deformation, ensuring circuit traces remain intact even in applications with mechanical stress (e.g., automotive engine bays, industrial machinery).

Controlled CTE Matching: The laminate’s coefficient of thermal expansion (CTE) is tailored to match adjacent components (e.g., semiconductors, connectors), minimizing thermal stress that can cause solder joint fatigue or trace cracking.

Corrosion Resistance: Surface treatments (e.g., chromate conversion, anodization) protect the aluminum core from moisture, chemicals, and oxidation, extending circuit lifespan in harsh environments.

Electrical Performance Optimization

Beyond thermal and mechanical benefits, the laminate enhances circuit functionality:

Low Dielectric Loss: The engineered dielectric minimizes signal attenuation at high frequencies (5G, Wi-Fi 6/7), ensuring reliable data transmission in communication circuits.

Impedance Control: Consistent dielectric thickness and copper uniformity enable precise impedance matching, critical for high-speed digital and RF circuits where signal integrity is paramount.

Insulation Resistance: The dielectric layer maintains high insulation resistance even under humidity, preventing leakage currents in high-voltage circuits (e.g., power inverters, battery management systems).

Application-Specific Circuit Solutions

Automotive Electronics: Power and Precision Circuits

Ventec’s aluminum-based circuit laminates are reshaping automotive electronics, particularly in:

EV Power Circuits: Inverters and DC-DC converters rely on the laminate’s thermal conductivity to manage high currents, ensuring efficient power conversion from batteries to motors. The mechanical stability prevents circuit damage from vehicle vibration.

ADAS Sensor Circuits: Advanced driver-assistance systems (ADAS) require compact, heat-resistant circuits for LiDAR, radar, and camera modules. The laminate’s low dielectric loss preserves signal integrity in high-frequency sensor circuits, while its stiffness maintains alignment of sensitive optical components.

Interior Electronics: Infotainment and lighting circuits benefit from the laminate’s design flexibility, enabling thin, lightweight boards that fit into space-constrained vehicle interiors without sacrificing performance.

Telecommunications: High-Frequency Circuit Reliability

In 5G and next-gen communication infrastructure, the laminate addresses key challenges:

Base Station Power Amplifiers: High-output RF amplifiers generate significant heat; the aluminum core dissipates this heat, maintaining amplifier efficiency and linearity. The low dielectric loss ensures minimal signal degradation in high-frequency (mmWave) circuits.

Small Cell Circuits: Compact small cell deployments (urban, indoor) require circuits that balance performance and size. The laminate’s thin profile and thermal efficiency enable dense component packing without overheating.

Data Center Server Boards: High-density server circuits with multiple CPUs and GPUs generate substantial heat. The laminate’s thermal management reduces the need for bulky heat sinks, enabling more compact server designs.

Industrial and Renewable Energy Circuits

Industrial environments demand circuits that combine durability with efficiency:

Motor Control Circuits: Variable frequency drives (VFDs) and motor controllers use the laminate to manage heat from IGBTs and gate drivers, ensuring reliable operation in factories and manufacturing plants.

Solar Inverter Circuits: PV inverter circuits convert DC power from solar panels to AC, generating heat in the process. The laminate’s thermal conductivity and weather resistance make it ideal for outdoor inverter enclosures.

Smart Grid Sensors: Distributed energy systems require sensors and communication circuits that operate in diverse climates. The laminate’s corrosion resistance and temperature tolerance ensure long-term reliability in these deployments.

Manufacturing Innovations in Laminate Production

Advanced Lamination Processes

Ventec’s manufacturing expertise lies in precision bonding of the three layers, ensuring optimal performance:

Roll-to-Roll Lamination: Continuous processing for high-volume production ensures uniform dielectric thickness and copper adhesion, critical for consistent circuit performance across batches.

Low-Temperature Bonding: Proprietary adhesives enable lamination at lower temperatures, reducing thermal stress on materials and preserving the integrity of sensitive dielectric fillers.

Cleanroom Manufacturing: Contamination control during lamination prevents microvoids or particles between layers, which could impair thermal or electrical performance in high-reliability circuits.

Material Integration for Custom Solutions

Recognizing that no single laminate fits all applications, Ventec offers customizable options through material integration:

Dielectric Variants: Options range from flexible polyimide-based dielectrics (for bendable circuits) to high-temperature epoxy-ceramic blends (for extreme environment circuits).

Copper Thickness Flexibility: Thin copper (for fine-pitch circuits) or thick copper (for high-current circuits) can be integrated, with bonding techniques optimized for each thickness to ensure adhesion and conductivity.

Surface Finish Compatibility: The laminate works with standard PCB surface finishes (e.g., ENIG, HASL, OSP), ensuring compatibility with existing assembly processes and component soldering requirements.

Quality Assurance and Compliance

Ventec’s aluminum-based circuit laminates undergo rigorous testing to meet industry standards:

IPC Compliance: Conformance to IPC-4101 (Specification for Base Materials for Rigid and Multilayer Printed Boards) ensures compatibility with PCB manufacturing processes and performance benchmarks.

Automotive Qualification: Compliance with IATF 16949 ensures laminates meet automotive industry quality management requirements, including traceability and process control.

Environmental Certifications: RoHS and REACH compliance confirms the absence of hazardous substances, aligning with global environmental regulations.

Testing protocols include thermal shock testing, humidity cycling, peel strength measurement, and dielectric breakdown testing, ensuring the laminate performs reliably throughout its operational lifecycle.

Emerging Trends and Future Developments

Integration with Flexible Electronics

Research is focusing on ultra-thin aluminum cores paired with flexible dielectrics, enabling bendable circuit laminates for wearable electronics, flexible displays, and conformable sensors. These laminates maintain thermal conductivity while adding the ability to curve around surfaces, expanding application possibilities.

AI-Driven Design Optimization

Machine learning tools are being integrated into laminate design, analyzing circuit layouts to recommend optimal laminate thickness, dielectric type, and copper weight. This ensures the laminate is tailored to the specific thermal and electrical needs of each circuit, reducing over-engineering and material waste.

Sustainable Manufacturing Practices

Ventec is advancing eco-friendly production methods, including:

Recycled Aluminum Content: Increasing the use of recycled aluminum in cores without compromising performance, reducing carbon footprint.

Solvent-Free Dielectrics: Developing water-based or UV-cured dielectrics to eliminate volatile organic compound (VOC) emissions during manufacturing.

Energy-Efficient Lamination: Optimizing heating and pressing processes to reduce energy consumption, aligning with global sustainability goals.

Conclusion

Ventec Aluminum Based Circuit Laminate represents a critical innovation in electronic materials, bridging thermal management, mechanical stability, and electrical performance to meet the demands of modern circuits. Its application across automotive, telecommunications, industrial, and renewable energy sectors underscores its versatility, while ongoing manufacturing and material advancements promise even broader utility in emerging technologies. For engineers and manufacturers seeking to optimize circuit performance in power-dense, harsh, or high-frequency environments, this laminate offers a proven, adaptable solution that balances functionality with reliability—solidifying its role as a cornerstone of next-generation electronic design.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB