-

- PCB TYPE

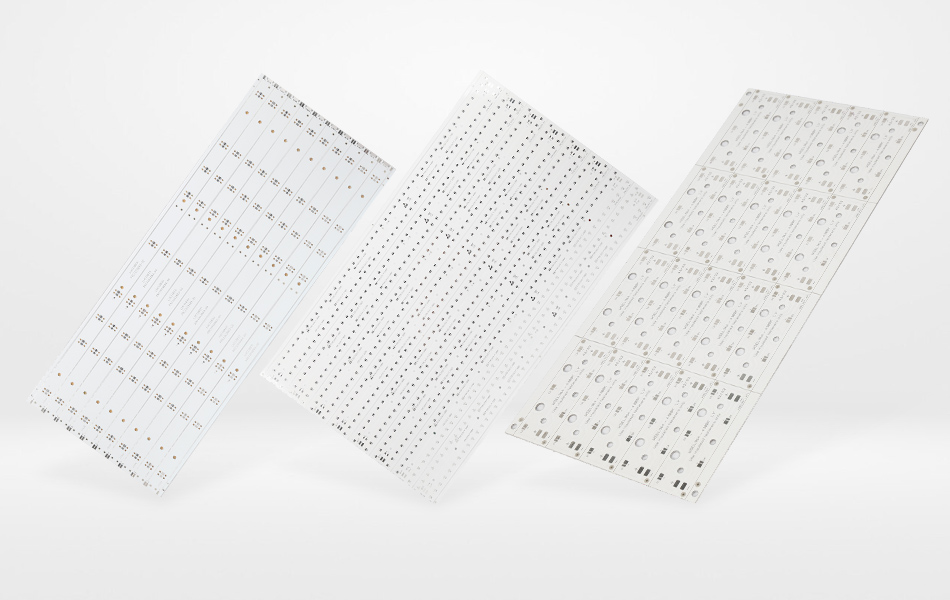

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 24. 2025, 09:29:35

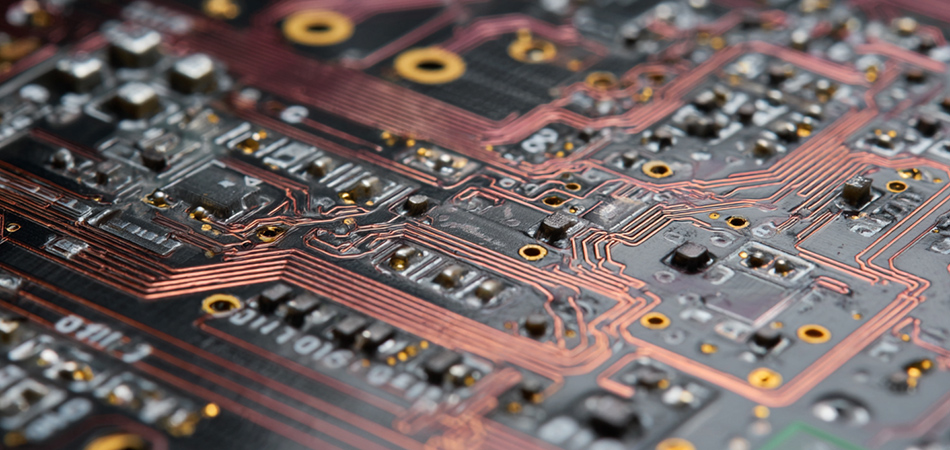

In the realm of advanced electronics, Wazam High Quality Aluminum PCB stands as a benchmark for reliability, thermal efficiency, and precision engineering, catering to industries where performance and durability are non-negotiable. As electronic systems grow increasingly power-dense and operate in harsher environments, the demand for high-quality aluminum PCBs has surged—Wazam meets this demand through uncompromising material standards, rigorous manufacturing controls, and a relentless focus on quality assurance. This article explores the pillars of Wazam’s high-quality aluminum PCBs, including material excellence, precision manufacturing, quality validation, and industry applications where quality drives success, ensuring industry industry expertise and alignment with search engine optimization (SEO) best practices.

Pillars of Quality: Material Excellence in Wazam Aluminum PCBs

Wazam’s commitment to high quality begins with meticulous material selection and engineering, ensuring each component meets stringent performance criteria:

Premium Material Sourcing and Formulation

Aluminum Substrate Quality: Wazam sources high-purity aluminum alloys with consistent thermal conductivity and mechanical properties, verified through rigorous material testing and traceability systems. This ensures the substrate provides uniform heat dissipation and structural stability, critical for avoiding hotspots and warping in high-power applications.

High-Grade Dielectric Materials: The dielectric layer uses pharmaceutical-grade ceramic-reinforced polymers or high-temperature polyimides, selected for low thermal resistance, stable electrical properties, and resistance to aging. These materials undergo extensive validation to ensure they maintain insulation strength and thermal performance over extended lifespans.

Ultra-Pure Copper Circuit Layers: Wazam uses high-purity copper foil (99.9%+ purity) to minimize electrical resistance and enhance heat spreading. The copper is tested for surface smoothness and uniformity, reducing signal loss and ensuring reliable solder joint formation during assembly.

This focus on material quality creates a foundation for aluminum PCBs that outperform standard alternatives in thermal management, mechanical resilience, and long-term reliability.

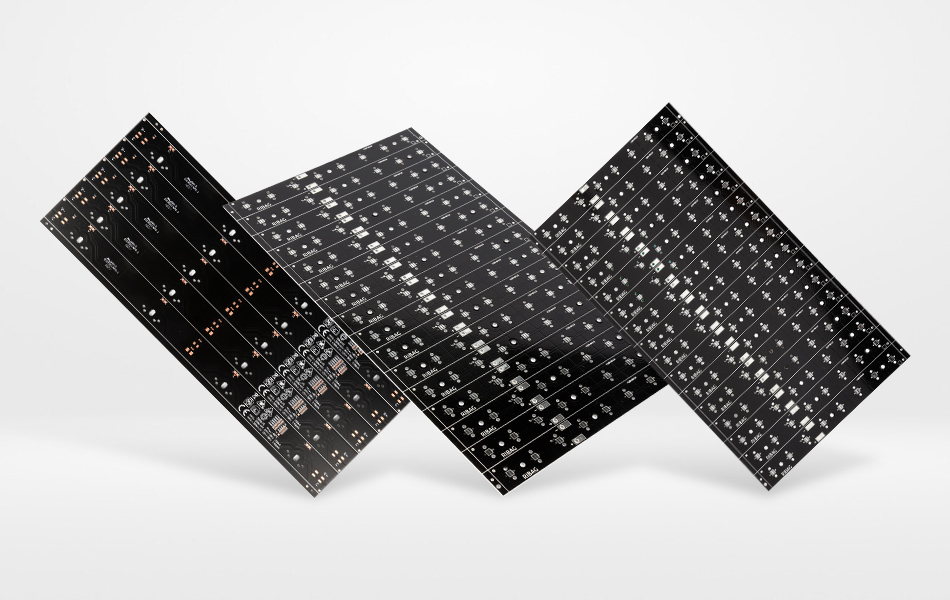

Precision Manufacturing: Quality-Driven Production Processes

Wazam’s manufacturing workflows are designed to uphold quality at every stage, from design to final inspection:

Advanced Production Controls

Cleanroom Manufacturing: Critical processes, such as lamination and etching, are performed in controlled cleanroom environments to minimize contamination—imperfections like dust or debris can compromise dielectric integrity or circuit conductivity, making this step vital for high-quality outcomes.

Automated Precision Lamination: Computer-controlled lamination systems ensure uniform pressure and temperature distribution, eliminating voids between layers. This prevents thermal resistance hotspots and enhances structural bond strength, a key factor in preventing delamination.

AI-Optimized Etching: Machine learning algorithms monitor etching processes to maintain tight tolerances for circuit traces and vias. This precision ensures impedance consistency in high-frequency applications and reduces variability between production batches.

Quality-Embedded Process Validation

Each manufacturing stage includes in-line testing, from material incoming inspections to post-etching circuit checks. This real-time validation allows for immediate correction of deviations, ensuring defects are caught before they impact final product quality.

Comprehensive Quality Assurance and Testing Protocols

Wazam’s high-quality aluminum PCBs undergo rigorous testing to validate performance across critical metrics:

Thermal Performance Validation

Infrared (IR) Thermal Mapping: PCBs are tested under simulated operating conditions to map temperature distribution, ensuring heat dissipates uniformly and no hotspots exceed safe thresholds for component reliability.

Thermal Cycling Testing: Samples undergo repeated temperature extremes to simulate long-term thermal stress, verifying that layer bonds and dielectric properties remain stable over time—critical for applications like automotive underhood systems or industrial ovens.

Mechanical and Environmental Durability Testing

Vibration and Shock Testing: PCBs are subjected to industry-standard vibration profiles and shock impacts to validate resistance to mechanical stress, ensuring they perform in high-vibration environments like aerospace or heavy machinery.

Corrosion and Moisture Resistance: Accelerated humidity and salt spray tests validate the effectiveness of surface treatments (anodization, conformal coatings), ensuring long-term durability in outdoor or high-moisture settings (e.g., renewable energy installations, marine electronics).

Electrical Performance Verification

High-Potential (Hipot) Testing: Ensures dielectric layers withstand high voltage without breakdown, critical for safety in high-voltage applications like power inverters.

Signal Integrity Analysis: Network analyzers and impedance testers validate signal transmission quality, ensuring low loss and consistent impedance in high-frequency applications such as 5G modules or radar systems.

These testing protocols ensure Wazam’s aluminum PCBs meet or exceed industry standards, with a defect rate far below average for the sector.

Industry Applications: Where High Quality Makes a Difference

Wazam’s high-quality aluminum PCBs excel in applications where reliability and performance directly impact safety, efficiency, or operational success:

Medical Electronics

In medical devices such as diagnostic equipment, patient monitors, and surgical tools, high-quality aluminum PCBs ensure stable performance and minimize failure risks. Thermal management prevents overheating in compact, enclosed devices, while electrical stability ensures accurate readings and safe operation.

Aerospace and Defense

Aerospace systems (avionics, satellite components) and defense electronics (radar, communication systems) demand PCBs that withstand extreme temperatures, radiation, and vibration. Wazam’s quality-driven design ensures these PCBs maintain performance in mission-critical scenarios where failure is not an option.

High-Reliability Industrial Systems

In industrial automation, particularly in sectors like semiconductor manufacturing or energy distribution, high-quality aluminum PCBs reduce downtime by minimizing failures in motor drives, PLCs, and power supplies. Their durability ensures consistent operation in dusty, high-temperature factory environments.

Premium Consumer Electronics

High-end consumer devices, such as professional-grade cameras, audio equipment, and smart home hubs, rely on Wazam’s aluminum PCBs for thermal efficiency and long lifespan. Quality materials and manufacturing reduce premature aging, ensuring devices perform reliably for years.

Quality Certifications and Continuous Improvement

Wazam’s commitment to quality is validated by adherence to global standards and a culture of continuous improvement:

Industry Certifications

IATF 16949: Compliance with automotive quality management standards ensures PCBs meet the rigorous reliability requirements of automotive electronics.

ISO 9001: A framework for consistent quality management, ensuring processes are documented, monitored, and optimized.

ISO 14001: Environmental management certification, aligning quality with sustainability through eco-friendly materials and processes.

Continuous Improvement Initiatives

Wazam invests in research and development to enhance quality, including:

Material Innovation: Collaborating with material suppliers to develop next-generation dielectrics and aluminum alloys with improved thermal conductivity and durability.

Process Optimization: Regular audits and feedback loops refine manufacturing workflows, reducing variability and enhancing efficiency without compromising quality.

Customer Feedback Integration: Post-delivery quality assessments and customer input drive iterative improvements, ensuring PCBs evolve with industry needs.

Conclusion

Wazam High Quality Aluminum PCB redefines excellence in electronic components, where quality is not just a standard but a core value embedded in materials, processes, and outcomes. By prioritizing material purity, precision manufacturing, and rigorous testing, Wazam delivers aluminum PCBs that excel in thermal management, mechanical resilience, and long-term reliability—critical for industries where performance and durability directly impact safety, efficiency, and customer trust. As electronics continue to advance, Wazam’s commitment to quality ensures it remains a trusted partner for high-reliability applications, setting the benchmark for what high-quality aluminum PCBs can achieve.

Keywords: Wazam High Quality Aluminum PCB, reliability, thermal management, quality assurance, precision manufacturing, aerospace electronics, medical devices, ISO certifications.

This article provides a focused, technically rigorous overview of Wazam’s high-quality aluminum PCBs, emphasizing quality-driven processes and applications while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB