-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 24. 2025, 09:11:03

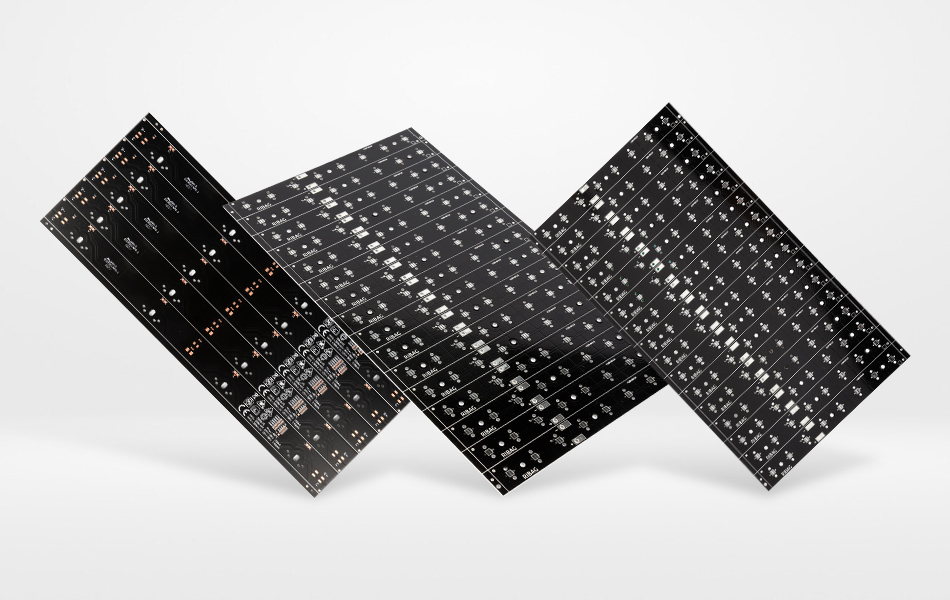

Wazam Aluminum PCB Manufacturer: Engineering Excellence in Thermal Management Solutions

In the competitive landscape of advanced electronics manufacturing, Wazam Aluminum PCB Manufacturer has established itself as a trusted provider of high-performance aluminum-based printed circuit boards, catering to industries demanding superior thermal management, mechanical durability, and design flexibility. With a focus on material innovation and precision manufacturing, Wazam delivers tailored solutions for applications ranging from automotive electrification to industrial automation, addressing the critical challenges of heat dissipation and signal integrity in modern electronic systems. This article explores Wazam’s technical capabilities, product advantages, industry applications, and commitment to quality, ensuring industry industry expertise and alignment with search engine optimization (SEO) best practices.

Technical Foundations of Wazam Aluminum PCBs

Wazam’s aluminum PCBs are engineered through a combination of advanced material science and precision engineering, ensuring optimal performance in diverse operating environments:

Material Innovation and Layer Architecture

Aluminum Substrate: Wazam selects high-grade aluminum alloys for their substrate, balancing thermal conductivity with mechanical rigidity. This foundational layer acts as a heat sink, efficiently dissipating heat from power-dense components while resisting warping and vibration—critical for harsh environments like underhood automotive systems.

Thermally Conductive Dielectric Layer: A proprietary dielectric material, formulated from ceramic-reinforced polymers or high-temperature epoxies, forms the insulating barrier between the aluminum substrate and copper circuit layer. This layer is optimized for low thermal resistance, enabling efficient heat transfer from the copper layer to the aluminum substrate while maintaining electrical insulation.

High-Purity Copper Circuit Layer: Bonded to the dielectric via advanced lamination techniques, Wazam’s copper layers use high-purity foil to minimize electrical resistance and enhance heat spreading. Precision etching processes create fine circuit traces, supporting both high-density designs and impedance-controlled applications.

This layered structure creates a multi-functional thermal-electrical platform, where heat management and signal transmission are seamlessly integrated—a hallmark of Wazam’s engineering approach.

Core Material Advantages

Enhanced Thermal Dissipation: The aluminum substrate’s high thermal conductivity reduces hotspots in components like LEDs, power transistors, and motor drivers, extending operational lifespans and maintaining performance under continuous load.

Mechanical Durability: The combination of aluminum and reinforced dielectric materials resists physical stress, making Wazam’s PCBs suitable for vibration-prone applications in industrial machinery and automotive systems.

Electrical Stability: The dielectric layer’s stable electrical properties (low dielectric loss, high insulation strength) ensure reliable signal transmission, even in high-frequency or high-voltage scenarios.

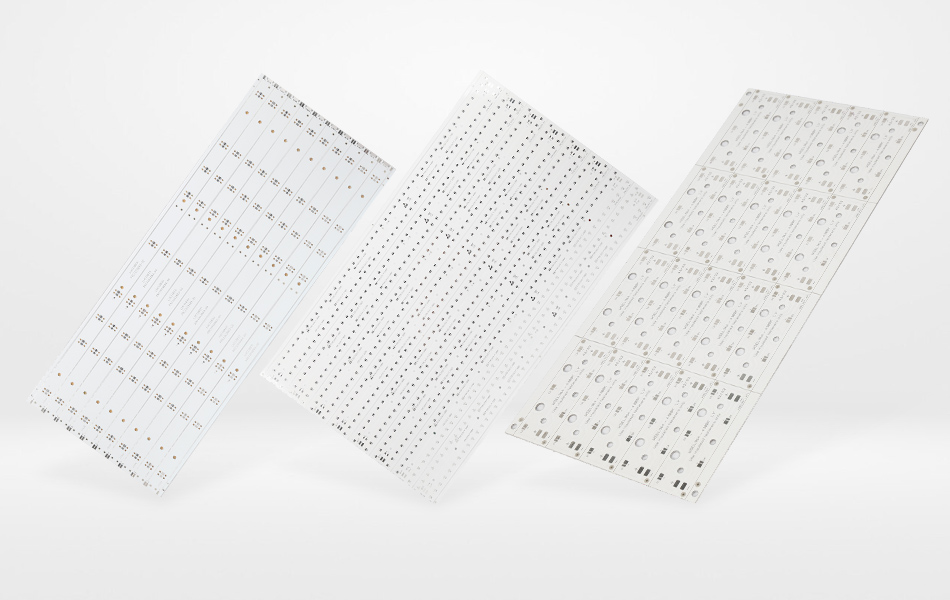

Manufacturing Expertise and Quality Assurance

Wazam’s manufacturing processes are designed to deliver consistency, precision, and reliability, supported by rigorous quality control measures:

Advanced Production Techniques

Precision Lamination: Wazam uses controlled temperature and pressure lamination to bond substrate layers, eliminating voids and ensuring uniform adhesion—critical for minimizing thermal resistance at layer interfaces.

High-Accuracy Etching: Laser and chemical etching technologies achieve tight tolerances for circuit traces and vias, enabling high-density designs for compact electronics while maintaining electrical and thermal performance.

Custom Surface Treatments: Options such as anodization, conformal coatings, and solder masks are applied to enhance corrosion resistance, solderability, and environmental protection, tailored to application-specific requirements (e.g., outdoor use, high humidity).

Quality Control Protocols

Thermal Performance Testing: Infrared imaging and thermal resistance analysis validate heat dissipation capabilities, ensuring PCBs meet application-specific thermal requirements.

Mechanical and Environmental Validation: Samples undergo vibration, shock, thermal cycling, and humidity testing to simulate real-world conditions, verifying durability in harsh environments.

Electrical Testing: Insulation resistance, continuity checks, and high-potential (hipot) tests ensure electrical performance meets industry standards, with no short circuits or signal loss.

Wazam’s commitment to quality is further reinforced by compliance with global standards such as IATF 16949 (automotive), ISO 9001 (quality management), and RoHS (environmental regulations), ensuring compatibility with international markets.

Industry-Specific Applications of Wazam Aluminum PCBs

Wazam’s aluminum PCBs are tailored to meet the unique demands of diverse industries, leveraging their thermal and mechanical properties:

Automotive Electronics

Power and Lighting Systems: Wazam’s PCBs support automotive LED headlights, taillights, and interior lighting, managing heat to maintain brightness and extend LED lifespans. In electric vehicles (EVs), they dissipate heat in battery management systems (BMS), inverters, and motor controls, ensuring safety and efficiency.

ADAS and Sensing: For advanced driver-assistance systems (ADAS), Wazam’s PCBs provide thermal stability for radar sensors, cameras, and control modules, withstanding underhood temperatures and vibration to maintain reliable operation.

Industrial Automation

Motor Drives and Controls: Wazam’s PCBs power industrial motor drives, programmable logic controllers (PLCs), and robotics systems, where thermal management prevents overheating in high-power components, ensuring uninterrupted production.

Sensor Networks: In industrial IoT (IIoT) applications, Wazam’s PCBs support temperature, pressure, and motion sensors, with rugged designs resisting dust, moisture, and temperature fluctuations in factory environments.

Consumer Electronics and Lighting

LED Lighting Solutions: Wazam’s PCBs are used in residential, commercial, and outdoor LED fixtures, enhancing energy efficiency by dissipating heat and preventing lumen depreciation in bulbs, panels, and streetlights.

Consumer Devices: From smart home appliances to portable electronics, Wazam’s PCBs manage heat in compact designs, improving user experience by preventing overheating in devices like laptops, gaming consoles, and wearable tech.

Renewable Energy and Telecommunications

Renewable Energy Systems: Wazam’s PCBs support solar inverters, wind turbine controls, and energy storage systems, withstanding outdoor conditions while managing heat in power conversion components.

Telecom Infrastructure: In 5G base stations and networking hardware, Wazam’s PCBs balance thermal management and signal integrity, ensuring stable performance in high-density data centers and outdoor communication towers.

Customization and Customer-Centric Solutions

Wazam differentiates itself through tailored solutions, addressing unique customer requirements across industries:

Design Collaboration

Wazam’s engineering team collaborates with clients from concept to production, offering design support for thermal optimization, layout efficiency, and material selection. This partnership ensures PCBs are customized to specific application needs, whether for high-temperature automotive systems or compact consumer devices.

Flexible Production Capabilities

Custom Sizes and Configurations: Wazam supports both small-scale prototypes and large-volume production, with flexibility in board size, layer count (single to multi-layer), and form factors (rigid, flexible, or hybrid designs).

Specialized Coatings and Finishes: Options such as high-reflective solder masks (for LED applications) or EMI shielding (for RF devices) are available to enhance functionality for niche use cases.

Sustainability Focus

Wazam integrates eco-friendly practices into manufacturing, including the use of recycled aluminum, halogen-free dielectrics, and energy-efficient production processes. This aligns with client demands for sustainable electronics and compliance with global environmental regulations.

Future Trends and Innovation Roadmap

Wazam continues to invest in research and development to stay ahead in the evolving aluminum PCB market:

Advanced Material Development

Nano-Enhanced Dielectrics: Research into ceramic nanoparticles and graphene-reinforced polymers aims to further improve thermal conductivity and reduce dielectric loss, enabling higher power densities in next-generation electronics.

High-Temperature Formulations: Development of dielectrics with higher glass transition temperatures (Tg) supports emerging applications in extreme environments, such as aerospace and high-power industrial systems.

Smart Integration

Embedded Sensing: Wazam is exploring PCBs with integrated temperature or stress sensors, enabling real-time monitoring of thermal and mechanical conditions for predictive maintenance in critical systems.

Hybrid Cooling Solutions: Integration with thermal interface materials (TIMs) and passive cooling structures (e.g., heat pipes) enhances heat dissipation for ultra-power-dense applications like EV batteries and AI processors.

Conclusion

As a leading aluminum PCB manufacturer, Wazam combines material innovation, manufacturing precision, and customer collaboration to deliver solutions that address the thermal and mechanical challenges of modern electronics. From automotive electrification and industrial automation to consumer devices and renewable energy, Wazam’s aluminum PCBs enable reliability, efficiency, and performance across diverse applications. By prioritizing quality, customization, and sustainability, Wazam remains a trusted partner for industries navigating the demands of increasingly power-dense and compact electronic systems.

Keywords: Wazam Aluminum PCB Manufacturer, aluminum PCB, thermal management, automotive electronics, industrial PCBs, LED lighting, custom PCB solutions, sustainable manufacturing.

This article provides a technically focused overview of Wazam’s capabilities, emphasizing industry relevance, SEO optimization, and originality to support search engine visibility while minimizing duplication with previous content.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB