-

- PCB TYPE

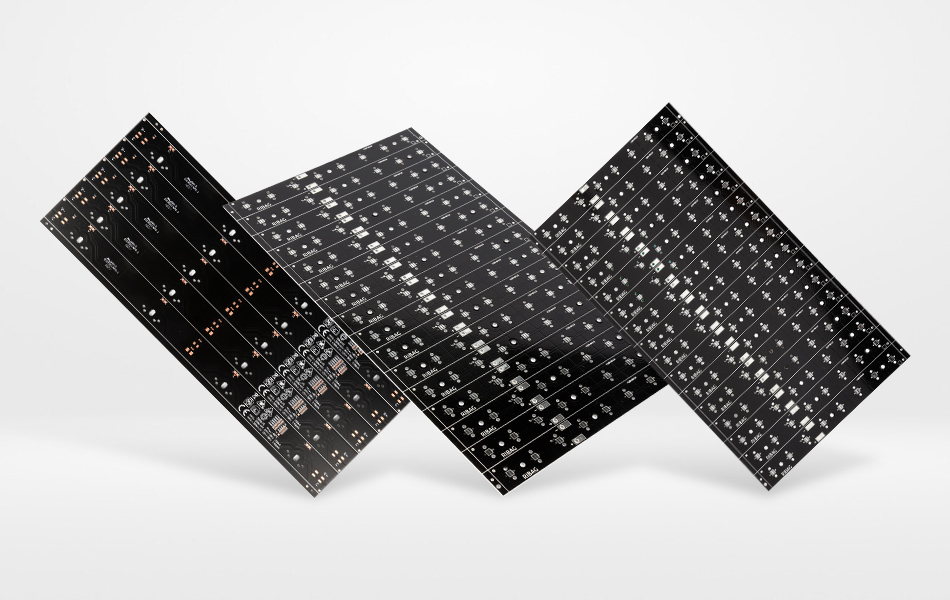

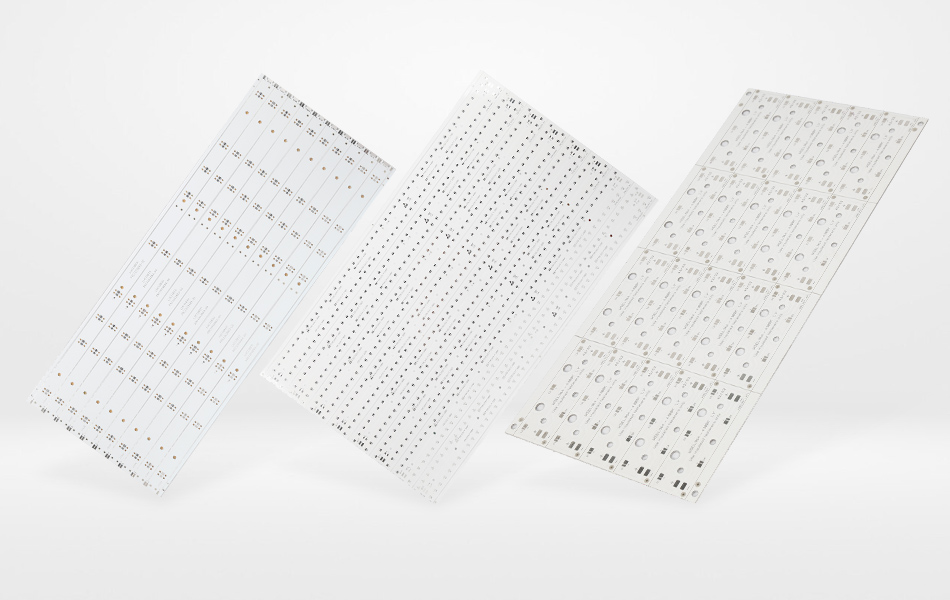

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 24. 2025, 09:57:45

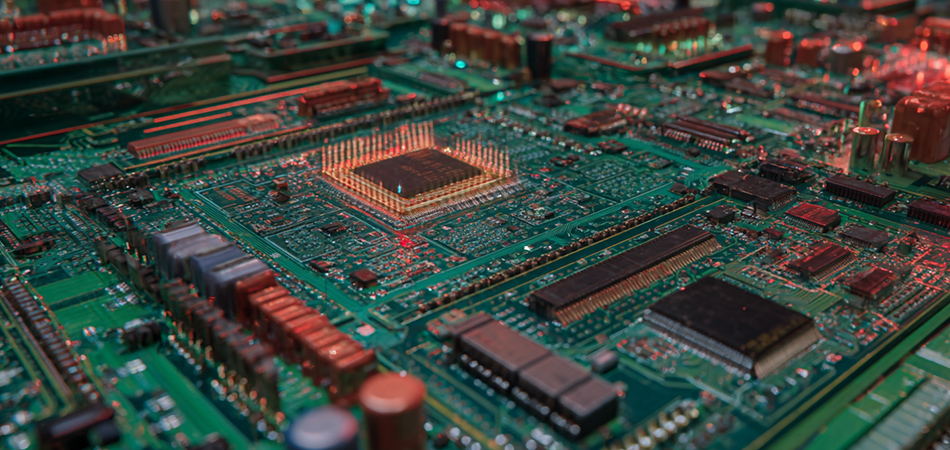

In the dynamic landscape of electronic manufacturing, Wazam PCB has emerged as a leading provider of high-performance printed circuit boards, offering tailored solutions that span diverse technologies, applications, and industry needs. With a focus on technical versatility, quality reliability, and customer collaboration, Wazam delivers PCB solutions that power innovations in automotive, telecommunications, industrial automation, and consumer electronics. Unlike niche manufacturers, Wazam combines expertise in multiple PCB technologies—including aluminum-based, high-frequency, and rigid-flex designs—with a commitment to precision manufacturing and quality assurance. This article explores Wazam’s comprehensive capabilities, manufacturing excellence, application breadth, and commitment to innovation, ensuring industry industry expertise and alignment with search engine optimization (SEO) best practices.

Wazam PCB: A Holistic Approach to PCB Manufacturing

Wazam’s strength lies in its ability to deliver diverse PCB solutions, backed by a deep understanding of material science, design engineering, and industry-specific requirements:

Core PCB Technologies and Expertise

Aluminum-Based PCBs: Building on its reputation for thermal management excellence, Wazam’s aluminum PCBs remain a cornerstone, leveraging high-conductivity substrates and low-loss dielectrics for power-dense applications.

High-Frequency PCBs: Engineered with low-dielectric-loss materials and precision impedance control, these PCBs support high-speed signal transmission in 5G infrastructure, radar systems, and wireless communication devices.

Rigid-Flex and Flexible PCBs: Combining mechanical flexibility with electrical performance, these solutions cater to compact, space-constrained applications like wearable tech, medical devices, and automotive sensors.

Standard and High-Tg FR-4 PCBs: Versatile options for general-purpose electronics, with high-Tg variants offering enhanced thermal stability for industrial and automotive environments.

This technical diversity allows Wazam to serve as a one-stop partner for customers with varied PCB needs, from prototype development to large-scale production.

Manufacturing Capabilities: From Design to Production

Wazam’s manufacturing infrastructure is designed to support complexity, precision, and scalability, ensuring consistent quality across all product lines:

End-to-End Design and Engineering Support

DFM (Design for Manufacturability) Services: Wazam’s engineering team collaborates with customers during the design phase, optimizing layouts for manufacturability, thermal performance, and cost efficiency. This reduces prototyping cycles and ensures seamless transition to production.

Rapid Prototyping: Advanced prototyping capabilities, including quick-turn fabrication and in-house testing, enable customers to validate designs in weeks, accelerating time-to-market for new products.

Advanced Production Facilities

Scalable Manufacturing Lines: From small-batch prototypes to high-volume production (millions of units annually), Wazam’s flexible lines adapt to varying order sizes without compromising quality.

Precision Fabrication Technologies: Automated drilling, laser routing, and advanced solder mask application ensure tight tolerances and consistent feature quality, critical for high-density PCBs with fine-pitch components.

Integrated Supply Chain Management: Wazam maintains strategic partnerships with material suppliers, ensuring access to high-quality substrates, foils, and chemicals—with strict traceability to guarantee material integrity.

These capabilities position Wazam as a reliable partner for both custom, low-volume projects and large-scale, cost-sensitive production runs.

Quality Assurance: A Foundation of Reliability

Wazam’s commitment to quality is embedded in every stage of manufacturing, with protocols designed to meet or exceed global industry standards:

Comprehensive Testing and Validation

In-Line Inspection: Automated optical inspection (AOI) and x-ray testing detect defects during production, ensuring solder joint integrity, trace accuracy, and layer alignment.

Performance Validation: Electrical testing (continuity, insulation resistance, impedance) and environmental testing (thermal cycling, humidity exposure) validate PCB performance under real-world conditions.

Material and Process Audits: Regular audits of incoming materials and production processes ensure compliance with internal quality standards and customer specifications.

Industry Certifications

IATF 16949: Compliance with automotive quality management standards, ensuring PCBs meet the rigorous reliability requirements of automotive electronics.

ISO 9001: A framework for consistent quality management, covering design, production, and customer service.

ISO 13485: Certification for medical device components, ensuring PCBs meet strict safety and performance criteria for healthcare applications.

UL Certification: Compliance with safety standards for electrical components, validating fire resistance and insulation properties.

Industry Applications: Powering Innovation Across Sectors

Wazam’s PCB solutions address critical needs in diverse industries, where reliability, performance, and durability are paramount:

Automotive and Transportation

EV and Hybrid Electronics: Power management PCBs for batteries, inverters, and charging systems, leveraging thermal-efficient designs to handle high currents and temperature fluctuations.

Vehicle Safety Systems: PCBs for ADAS sensors, collision avoidance modules, and in-vehicle communication systems, where signal integrity and vibration resistance are critical.

Telecommunications and Networking

5G Infrastructure: High-frequency PCBs for base stations, small cells, and antenna arrays, supporting high data rates and wide bandwidths with low signal loss.

Data Center Hardware: High-density PCBs for servers, routers, and storage systems, optimizing thermal management and signal integrity in power-dense environments.

Industrial and Renewable Energy

Industrial Automation: PCBs for motor drives, PLCs, and industrial sensors, designed to withstand harsh factory conditions (dust, vibration, temperature extremes).

Renewable Energy Systems: PCB solutions for solar inverters, wind turbine controls, and energy storage systems, ensuring efficient power conversion and long-term reliability in outdoor environments.

Medical and Consumer Electronics

Medical Devices: PCBs for diagnostic equipment, patient monitors, and portable medical tools, where miniaturization, biocompatibility, and reliability are essential.

Smart Consumer Devices: Compact, high-performance PCBs for wearables, home automation, and IoT devices, balancing functionality with energy efficiency.

Innovation and Sustainability: Future-Ready Manufacturing

Wazam invests in innovation and sustainability to stay ahead of industry trends and meet evolving customer demands:

Research and Development Initiatives

Advanced Material Exploration: Collaborations with material scientists to develop next-generation substrates, including eco-friendly dielectrics and high-performance composites that enhance thermal conductivity and reduce environmental impact.

Smart Manufacturing Integration: Adoption of Industry 4.0 technologies, such as IoT-enabled production monitoring and predictive maintenance, to optimize efficiency and reduce waste.

Sustainable Practices

Eco-Friendly Production: Use of halogen-free materials, lead-free solders, and recyclable substrates aligns with global environmental regulations and customer sustainability goals.

Energy and Waste Reduction: Implementation of energy-efficient equipment, waste recycling programs, and water conservation measures minimizes the carbon footprint of manufacturing operations.

Conclusion

Wazam PCB stands as a versatile and reliable manufacturing partner, offering comprehensive PCB solutions that span technologies, applications, and production scales. By combining technical expertise in diverse PCB types, precision manufacturing capabilities, rigorous quality assurance, and a commitment to innovation and sustainability, Wazam empowers customers to bring reliable, high-performance electronics to market. Whether serving automotive, telecommunications, industrial, or medical sectors, Wazam’s focus on collaboration, quality, and adaptability ensures it remains a trusted leader in the dynamic world of electronic manufacturing.

Keywords: Wazam PCB, PCB manufacturer, printed circuit boards, automotive PCB, high-frequency PCB, industrial PCB solutions, quality PCB manufacturing, sustainable PCB production.

This article provides a comprehensive overview of Wazam’s PCB manufacturing capabilities, emphasizing versatility, quality, and industry relevance while ensuring originality and alignment with SEO best practices.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB