-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Oct 20. 2025, 15:47:11

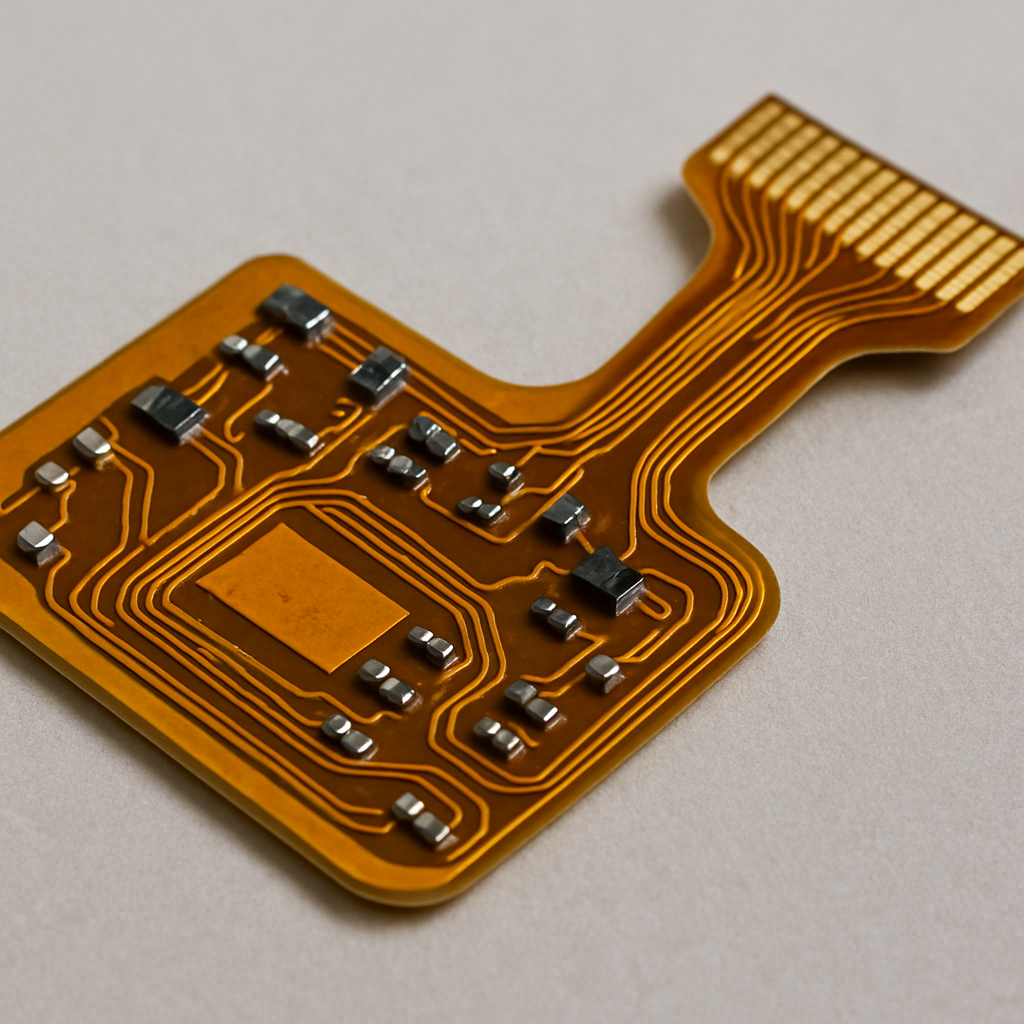

In today's technology-driven world, the demand for innovative and compact electronic devices is skyrocketing. Among the forefront of these advancements are wearable technologies, which require special attention in their design and manufacturing processes. A significant component of these devices is the flexible printed circuit board (PCB). This article will delve into the importance of wearable flex PCB assembly services, the benefits they offer, and how they play a crucial role in the development of wearable technology.

Wearable flex PCB assembly refers to the process of designing and assembling flexible circuit boards that are used in wearable devices. Unlike traditional rigid PCBs, flexible circuit boards can bend, fold, and fit into the compact spaces of wearable gadgets. This flexibility is what makes them ideal for the unique demands of wearable technology, such as fitness trackers, smartwatches, and medical devices.

Flexible PCBs offer incredible design flexibility. Their ability to bend and twist means that they can fit into tight spaces and unique shapes, which is crucial for the sleek and ergonomic design of modern wearables. This capability allows designers to create more compact and lightweight devices without compromising on functionality.

Wearable devices are often subjected to constant movement and environmental stress, such as moisture and heat. Flexible circuit boards are designed to withstand these conditions, offering durability and reliability. They are less prone to damage from vibrations and impacts, ensuring the longevity of the wearable device.

Flexible circuit boards can accommodate more complex circuits, allowing for enhanced performance of wearable devices. They support high-density connections and can integrate more functionalities into a smaller space. This leads to better performance and more features in wearable technology.

The first step in the assembly process is designing the flexible PCB. This involves creating a layout that meets the device's specifications and requirements. Prototyping is then conducted to test the design and make necessary adjustments. This stage is crucial to ensure that the final product functions correctly and efficiently.

Choosing the right materials is essential for the success of wearable flex PCB assembly. The materials must be flexible yet robust enough to handle daily wear and tear. Common materials used include polyimide and polyester, which provide the necessary flexibility and durability.

Once the design is finalized and materials are selected, the next step is component assembly. This involves placing and soldering components onto the flexible PCB. Due to the delicate nature of flexible circuits, precision in assembly is critical to avoid damaging the board.

After assembly, rigorous testing is conducted to ensure the functionality and reliability of the PCB. Quality assurance processes check for any defects or issues that could affect the device's performance. This step is vital to maintain high standards and ensure customer satisfaction.

Opting for professional PCB assembly services provides access to expert knowledge and experience in handling flexible circuit boards. Experienced technicians understand the intricacies of designing and assembling wearables, ensuring high-quality output.

Advanced Technology and Equipment

Professional services use the latest technology and equipment for PCB assembly. This includes state-of-the-art machinery for precise component placement and soldering, which is essential for the delicate nature of flexible PCBs.

While it might seem more economical to handle PCB assembly in-house, outsourcing to a professional service can be more cost-effective in the long run. They reduce errors and waste, leading to lower overall production costs. Additionally, their expertise can lead to better product performance and a quicker time-to-market.

Flexible PCBs are integral to fitness trackers, which require lightweight and compact designs to be worn comfortably. They enable the integration of sensors, Bluetooth connectivity, and other features into a small form factor.

In the medical field, wearable devices such as heart rate monitors and glucose meters rely on flexible PCBs for their functionality and comfort. These devices require reliability and precision, which flexible circuit boards provide.

Smartwatches are another popular application of wearable flex PCBs. The flexibility of the PCB allows for a sleek design that can incorporate various functionalities, such as GPS, Wi-Fi, and mobile connectivity.

The rise of wearable technology has highlighted the need for specialized components that can meet the unique demands of these devices. Wearable flex PCB assembly services offer the expertise, technology, and solutions needed to produce high-quality flexible circuit boards. By choosing professional assembly services, manufacturers can ensure that their wearable devices are durable, reliable, and capable of delivering exceptional performance.

Investing in the right PCB assembly service is a crucial step towards success in the competitive world of wearable technology. Whether for fitness, health, or convenience, flexible circuit boards are at the heart of innovation in wearables, enabling the creation of devices that enhance our daily lives.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB