-

- PCB TYPE

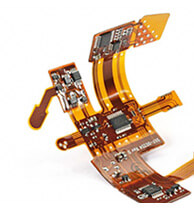

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Sep 17. 2021, 10:52:35

Module circuit board manufacturers will encounter the problem of printed circuit board warpage during the production process, and warpage will cause the problem of inaccurate positioning of components; then what factors should be paid attention to in the process of printed circuit board, or is there any way to avoid printing The circuit board will not warp. Today I will teach you how to deal with this problem; when the board is bent in SMT, THT, the component pins are not straight, which will bring a lot of difficulties to the assembly and installation work; IPC-6012, SMB-- SMT circuit boards have a large warpage or torsion of 0.75%, and other boards generally do not exceed 1.5%; the allowable warpage of electronic assembly plants (double-sided/multi-layer) is usually 0.70---0.75%, ( 1.6mm board thickness) In fact, many boards such as SMB and BGA boards require warpage less than 0.5%; some factories even less than 0.3%; PC-TM-650 2.4.22B warpage calculation method = warpage height/curved edge length;

Preventive method of module circuit board warping:

1. Engineering design: the arrangement of the interlayer prepreg should correspond; the multilayer core board and the prepreg should use the same supplier's product; the outer C/S surface pattern area should be as close as possible, and independent grids can be used;

2. Drying the board before cutting: generally 150 degrees for 6-10 hours, removing the moisture in the board, further curing the resin completely, eliminating the stress in the board; baking the board before cutting, whether the inner layer or both sides are required!

3. Pay attention to the warp and weft direction of the cured sheet before laminating the multi-layer board: the shrinkage ratio in the warp and weft direction is different, pay attention to distinguish the warp and weft direction before cutting the prepreg sheet; pay attention to the warp and weft direction when cutting the core board; generally the board is cured The direction of the film roll is the warp direction; the long direction of the copper clad laminate is the warp direction;

4, lamination thickness to relieve stress, cold press after pressing the board, trim the burrs;

5. Baking board before drilling: 150 degrees for 4 hours;

6. The thin plate is not mechanically brushed, and chemical cleaning is recommended; special fixtures are used during electroplating to prevent the plate from bending and folding;

7. After spraying tin, cool naturally to room temperature on flat marble or steel plate or clean it after cooling in air flotation bed; warped plate treatment: 150 degrees or hot pressing for 3-6 hours, using flat and smooth steel plate to repress, 2-3 Second baking;

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB